With a 169 year history, Gilbert Gilkes & Gordon (Gilkes) designs and manufactures hydropower turbines and pumps, exporting to over 85 countries. The company supplies pumps to the marine, rail and automotive sectors and hydropower turbine systems installed as far afield as Alaska and Australia.

Created in 1853 to manufacture agricultural equipment, under the name of Williamson Brothers, the company’s first order for a turbine was registered in 1865. It was in 1881 that Dublin-born businessman Gilbert Gilkes purchased the company and a prestigious customer at that time, Lord Armstrong, installed a water turbine at his home, Cragside, the first house to have electric lighting.

Many of its products harness the natural power of water flowing in rivers, described as run of river systems. “Wear has always been an issue given the application, so we are constantly looking at new, more exotic materials, to help reduce wear and to extend operating time. Most recently we have utilised tungsten carbide coatings on the runner systems within our turbines. This posed challenges to our in-house production team who worked closely with Ceratizit to achieve the desired result,” says Derek Thomas, Gilkes’ Production Engineering Manager.

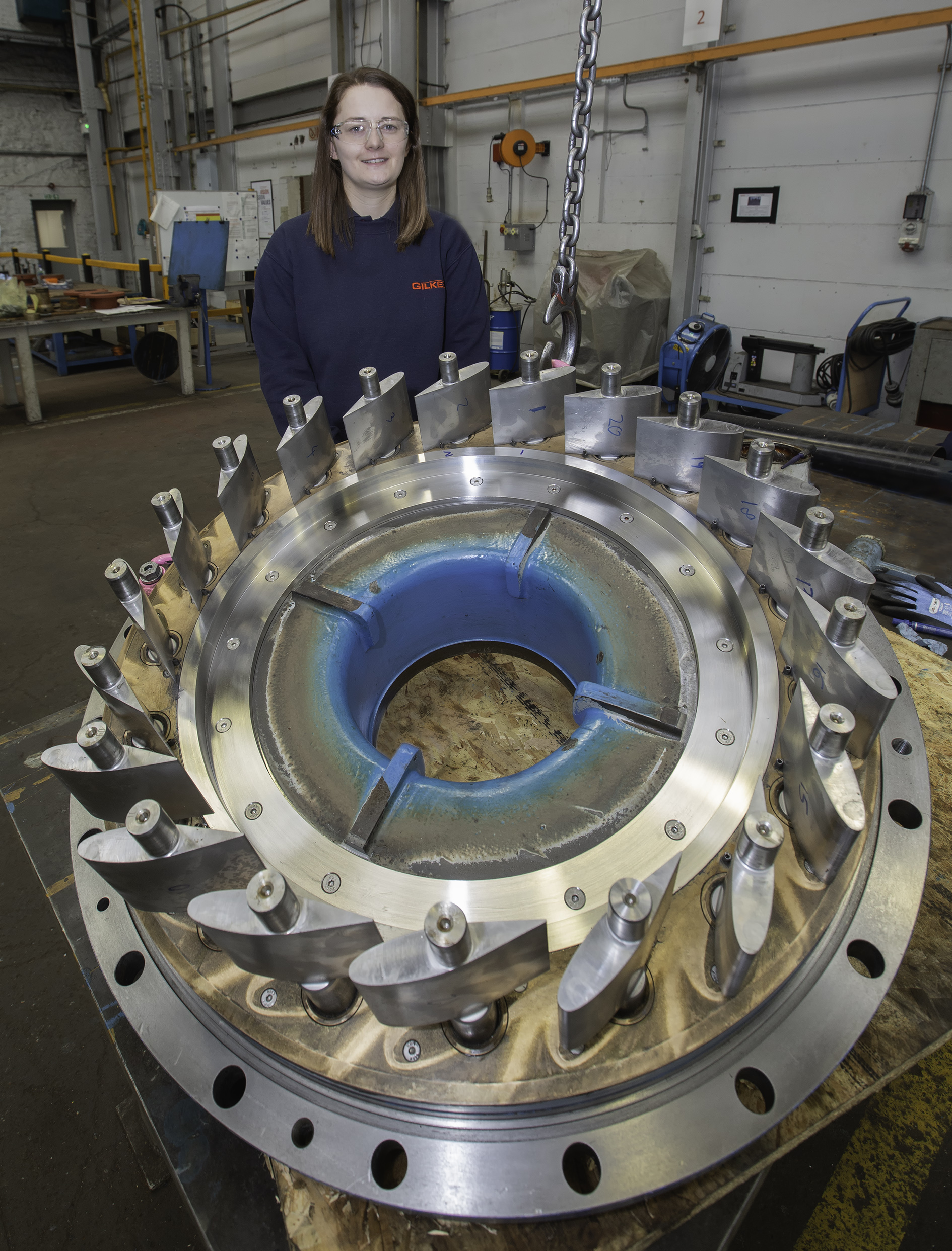

The part in question was a 600mm diameter F35 Super Duplex ring that was subject to abrasion from sediment. To overcome this, Gilkes added a Tungsten Carbide coating, the application of which caused out of roundness, which then had to be machined away. The challenge was how to remove this excess material. Matthew Darbyshire from Ceratizit suggested a new insert grade that would allow us to turn the part on the Mazak.”

The insert was a brand new CBN grade CTBH 40U, which had been developed for turning hardened materials where the intermittent cutting was an issue. Two inserts with cutting data of 210m/min surface speed and 0.12mm/rev feed rate with a 0.25mm depth of cut were suggested by Matt for testing. “The result was superb, just one insert was needed to complete the machining operation and the surface finish was excellent. The insert cut the tungsten carbide coating like a dream,” says Production Engineer Justine Marshall.

In the case of Gilkes, Matt visits on a fortnightly basis to discuss any upcoming requirements as well as servicing the two Ceratizit tool vending machines on-site. One of these vendors is the latest TOM 840 unit capable of storing up to 840 individual items with monitoring and reordering done remotely by Ceratizit, this unit is used to stock regular consumable cutting tools, such as inserts and drills. While the second vendor is an older TOM 60 system, which Gilkes maintains for tooling such as special taps and regrinds. The use of this older system, with its glass front, is due to the preference of Gilkes’ operators who want to physically see stock levels of these lesser used, but vital tools.

“The support we give to the team at Gilkes is what we would provide to any customer. The vending solution covers the vast majority of their day-to-day needs, and my regular visits take care of everything else,” says Matthew Darbyshire, Technical Sales Engineer, Ceratizit UK & Ireland. “We have worked together for over 16 years now. This ensures that things run smoothly. In addition to new tools, we also take care of regrinds of Ceratizit products, collecting them every month to be returned to the factory to be refreshed to original condition. We also provide a recycling service for used carbide inserts. These are collected every quarter and their value is returned to Gilkes in the form of a rebate on new products.”

“The support we give to the team at Gilkes is what we would provide to any customer. The vending solution covers the vast majority of their day-to-day needs, and my regular visits take care of everything else,” says Matthew Darbyshire, Technical Sales Engineer, Ceratizit UK & Ireland. “We have worked together for over 16 years now. This ensures that things run smoothly. In addition to new tools, we also take care of regrinds of Ceratizit products, collecting them every month to be returned to the factory to be refreshed to original condition. We also provide a recycling service for used carbide inserts. These are collected every quarter and their value is returned to Gilkes in the form of a rebate on new products.”