On Stand 460 in Hall 20, the Carfulan Group will be demonstrating its portfolio of products with metrology, additive manufacturing, tool pre-setting and turned part measurement technology on show from OGP UK, SYS Systems, ZOLLER UK and VICIVISION UK.

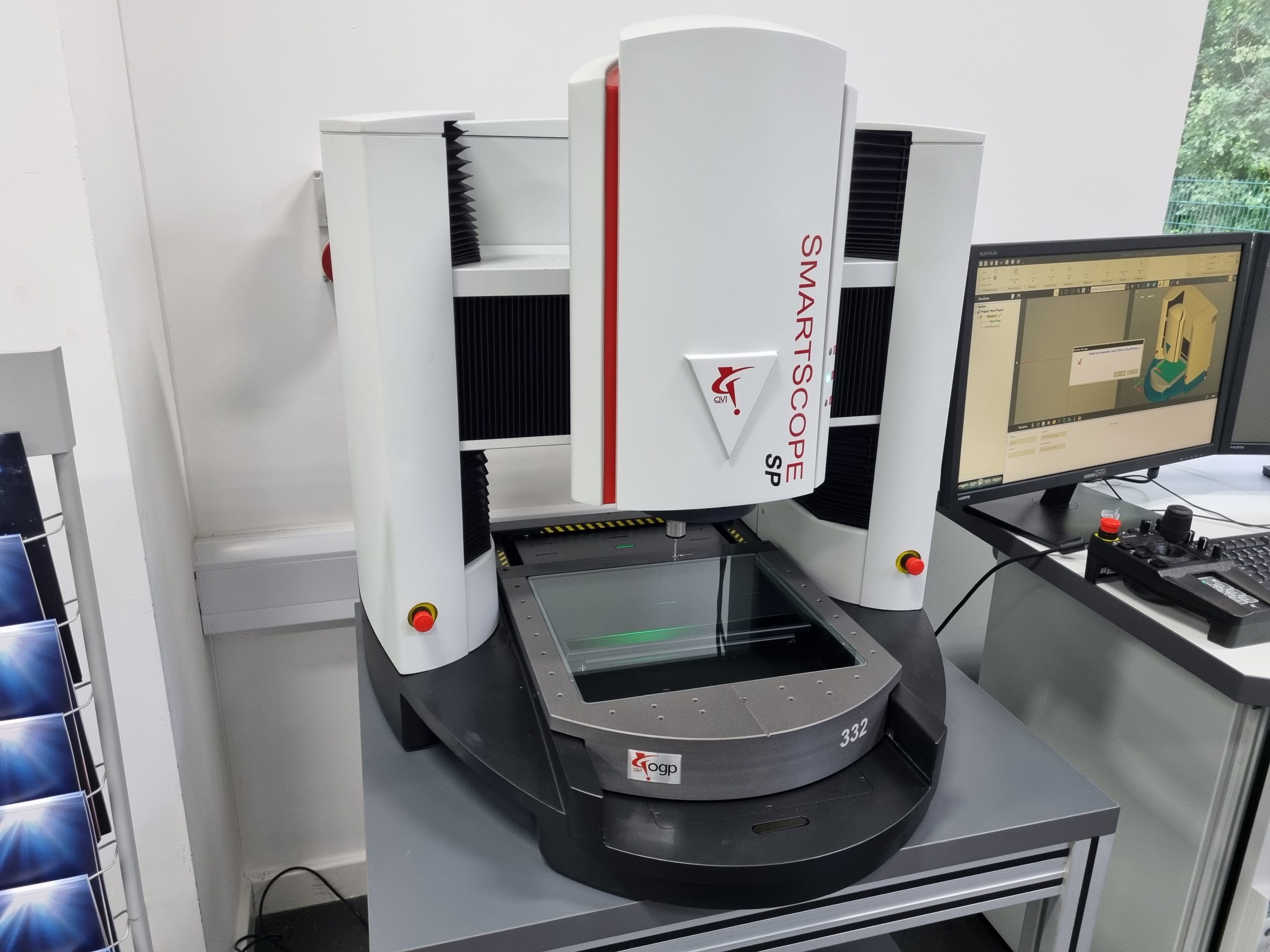

OGP UK will present its SmartScope Vantage 450 machine, designed to combine a variety of sensors for full 3D measurement. This system delivers optical performance alongside the highest standards of accuracy, repeatability and speed. Appearing alongside it will be the Smartscope CNC 200, CNC 500 and SP332. The CNC 200 and CNC 500 generate multi-sensor measurements, maintaining accuracy whilst withstanding the most hostile of environments. Generation of automatic component measurements alongside multi-sensor deployment mechanisms allow for unmanned inspection and high component throughput.

SYS Systems will be showcasing a selection of Stratasys 3D printing machines. Suitable for a variety of applications, the F900, Fortus 450 and F370 systems will all be on show, as well as the J35 Pro PolyJet 3D printer which is revolutionising desktop prototyping. The F900 machine can print 16 materials from engineering-grade thermoplastics to high-performance polymers and is suited for early prototyping, functional prototyping, end-use parts, production tooling and more. The soluble support materials can produce complex geometries in one print without assembly. The high-strength material capability of Stratasys FDM technology is the standard in carbon fibre printing for tools and end-use parts that demand high strength and stiffness.

For machine shops to tool manufacturers, the ZOLLER UK setting, measuring and tool pre-setting machines will be on show. The SmileCompact, Smile Pilot 1, Pilot 4 and Redomatic will preset and measure cutting tools offline with speed. Designed to work quickly and ergonomically in the manufacturing environment, the Smile range assesses tool length, diameter, radius, angle, concentricity and axial run-out in just seconds using pilotStarter image processing and touch-screen technology, as well as showcasing zidCode data transfer technology.

VICIVISION UK will show the X360, the brand new Prima 306, Techno M614 and the M309. For measuring the smallest of details, the X series of optical measuring devices have been designed to measure micro-mechanical components and general micro-parts. The high-resolution machines detect the smallest of details, measuring everything from cylindricity, roundness, axial and radial run-out.

To optimise performance in smart automated factories, VICIVISION UK will also demonstrate the Metrios 2D digital optical measuring machine. At the press of a button, this versatile system performs accurate and objective part-quality tests directly on the shop floor, driving increased productivity and reducing both scrap and costs. Using automatic position detection with 100x magnification power and capable of inspecting multiple parts at the same time, complex measurements such as distances, angles, radii, diameters and roundness can be taken in seconds, all with a simple and intuitive click.