Duncan Dunbar established Dunbar Race Engineering in Dalbeattie in 2018 to design and supply prototype parts for the motorsport market. The company also reverse-engineers and remanufactures parts that are no longer available for historic and emerging classic racing motorbikes.

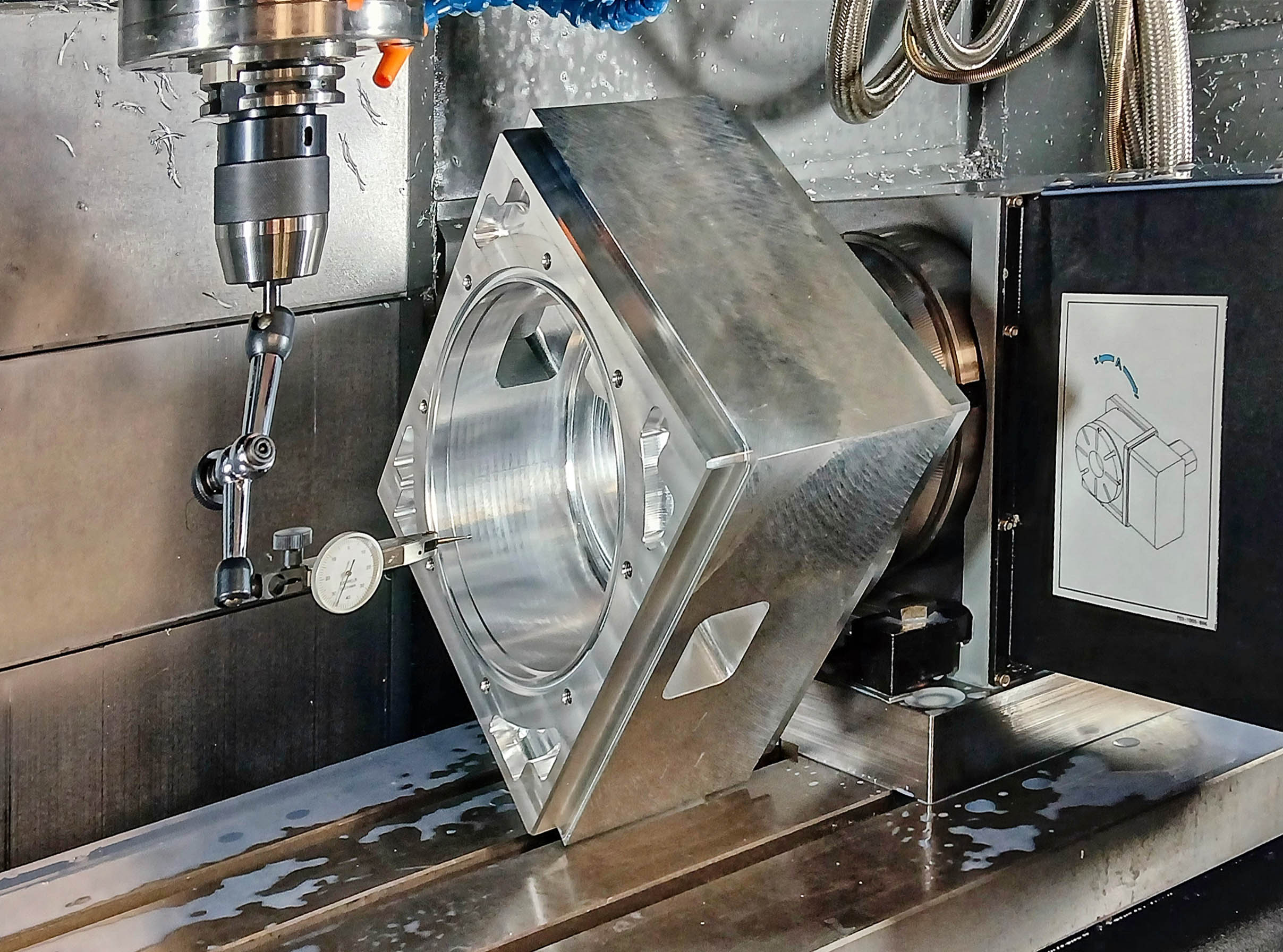

Initially, part production was outsourced to subcontractors. However, Duncan realised that to increase flexibility, reduce lead times, and ensure consistent quality, it would be necessary to transition from a home workshop to in-house manufacturing. Thus, in the spring of 2022, he relocated the company to an industrial unit and purchased a Hurco VM10i 3-axis VMC equipped with a 4th-axis rotary table.

Before deciding on the Hurco VMC, Duncan thoroughly researched the market. Hurco was recommended by a former colleague, which led to a visit to the supplier’s High Wycombe facility. As he was new to machining, he sought more than just a machine tool provider; he looked for a company with which Dunbar Race Engineering could partner. Critical to him was the assistance during the early stages of first-time CNC programming and a clear path to more advanced machining capabilities in the future. Duncan confirmed that Hurco’s training was excellent, and its applications engineers provided substantial support with programming and guidance on how different jobs should be set up.

Duncan described his experience with Hurco: “They are nice people to work with and the VM10i is a cracking machine. It has a large working area for its footprint and fits neatly into the space we had available.”

To produce excellent-quality parts with fine tolerances, sometimes as tight as ±10 microns, the manufacturer fully takes advantage of both the Hurco machine’s build quality and the conversational programming power of the WinMax control, which Duncan states is easy and intuitive to use. Most work, including complex jobs requiring 3+1-axis machining, is programmed directly at the control. Toolpath simulation and verification graphics help prevent potential input mistakes. “What you see on the screen is what you get on the part,” Duncan confirmed.

His career as a mechanical design engineer began with superbikes and MotoGP and continued with Mercedes AMG High Performance Powertrains. He retains a passion for all things motorsport but is keen to emphasise that Dunbar Race Engineering is not solely a racing company. He believes that the discipline, drive, and innovation that foster a career in motorsport can be applied to deliver design projects and manufacture products for a wide range of mechanical systems.

Additional expertise, including inspection and quality management system services using a Mitutoyo coordinate measuring machine, are offered. Customers also benefit from the experience of time-served manufacturing engineers who can be called upon at any stage of a project to analyse, redesign, and improve a process ahead of final sign-off.