🎧Bringing 5-axis to every UK machine shop

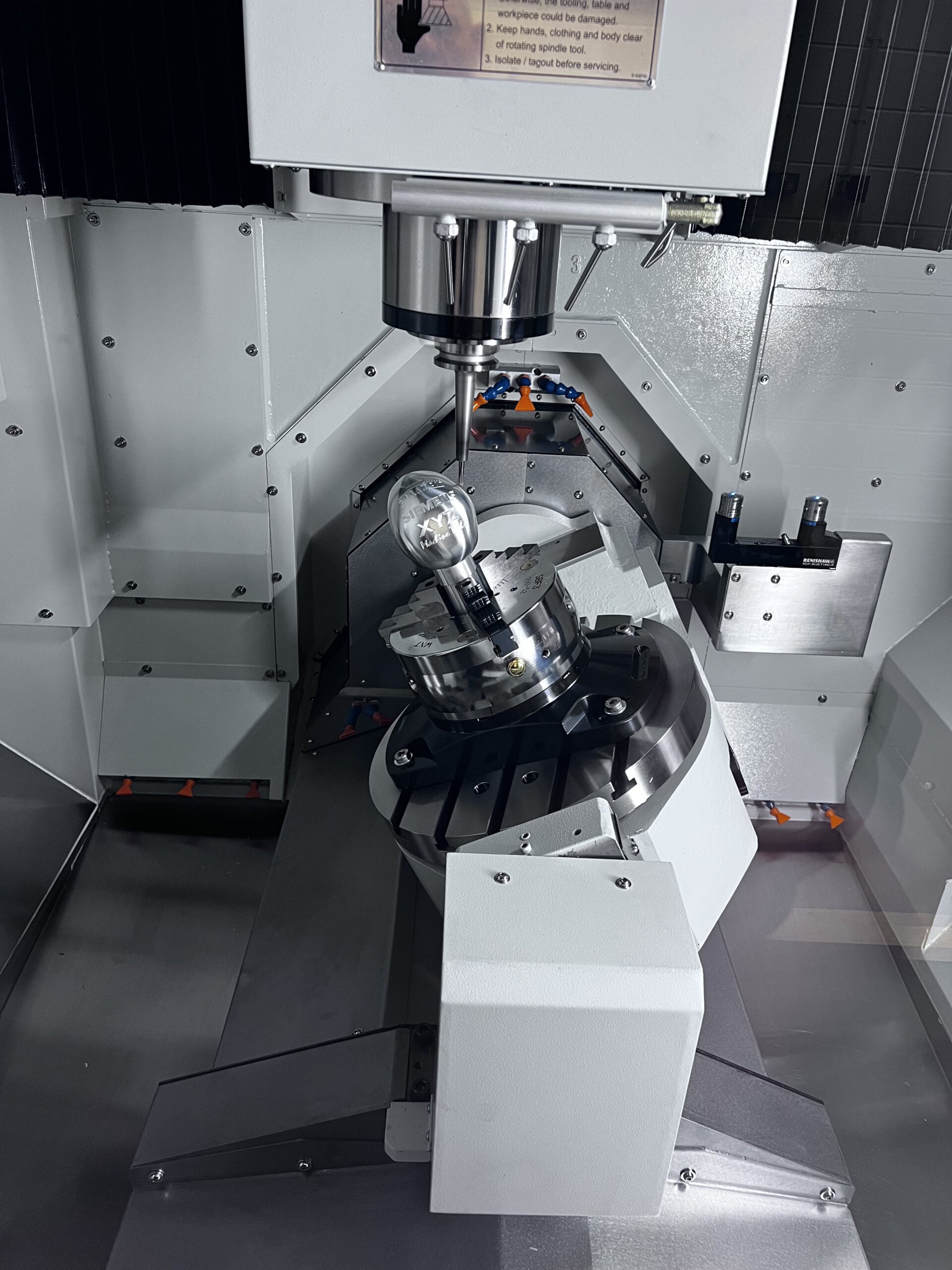

During my childhood, kids would play ‘pinch, punch, first of the month’, but on October 1st, XYZ Machine Tools brought a genuine ‘pinch me, punch me and wake me up moment’ with the unveiling of their new XYZ 400 UMC 5-axis machining centre. Why? The build, kinematics, quality and specs are imposing, but the ‘wake me up moment’ was the price point that XYZ’s Managing Director believes can bring 5-axis to ‘every machine shop in the UK’ – at a price marginally above a typical VMC, has XYZ broken the final barrier to 5-axis entry? By Rhys Williams

Presented at a press seminar at their Devon headquarters to unveil the new machine, XYZ believe this machine will fundamentally change the landscape of 5-axis machining in the UK. The day-long event provided detailed insights into not just the technical specifications of the new 400 UMC, but also the company’s broader vision for addressing the manufacturing skills shortage, embracing automation, and leveraging artificial intelligence to boost productivity.

The Strategic Vision:

5-Axis for Every Workshop

XYZ Managing Director Martin Burton set the tone for the launch with an ambitious declaration: “We want to bring 5-axis machining into every workshop in the UK.” This wasn’t mere hyperbole – it represented a carefully considered strategy that had been 18 months in the making.

The genesis of the 400 UMC lies in XYZ’s relationship with their existing customer base. Since launching their first 5-axis machine, the UMC 5X in 2017, the company has built a strong reputation for high-technology machining solutions. However, at a £220,000 entry point, the 5X represented a significant investment barrier for many workshops. Burton explained the fundamental challenge: “One of the biggest things that we wanted to bring to this was you don’t have to decide today whether you need 4+1 or 5-axis, because if you’ve got that decision to make, you’re going to go for a 5-axis. Because you’d be foolish as a businessman to take that risk.”

Listening to the Market

XYZ’s development process was driven by extensive customer feedback. Mike Corbett, the company’s long-serving technical expert, emphasised: “At XYZ, we listen to our existing users – a lot. Our sales team are going around the country all of the time getting feedback from our customers about where they need to move with their machining capability.”

This feedback revealed several key requirements: customers wanted a smaller footprint machine, less capacity than the 600mm table on the 5X, a more cost-effective rotary table that didn’t need to rotate at 90rpm, but critically, they still demanded excellent build quality. And, perhaps unsurprisingly, they wanted to spend less money.

The Price Point Challenge

Burton was remarkably candid about the pricing strategy discussions with King Rich, their Taiwanese manufacturing partner: “The target and discussions that we’ve had for the last 18 months, our target price was always £100,000, as I wanted to get the price as close to a VMC price as possible.”

This represented a strategic inflexion point. Burton continued: “The negotiations around the table that we’ve had are that you can’t compromise on quality. We want this machine to perform like all of our other products – that’s a minimum. We want 400mm capacity. That’s it. Don’t try and make it bigger. Don’t try and bring in extra stuff. Let’s stick to the profile that we put together.”

Burton explained the decision on the rotary table: “How do we get that table to be a better price? Direct Drive tables were not at the forefront of anyone’s decision; it was a lot of technology that people don’t really need – take that out. But we want a really good table because we don’t like traditional worm and wheel.”

The resulting launch price is £110,000 for the 30-station tool changer version and £125,000 for the 60-station variant – roughly half the cost of the UMC 5X, positioning the 400 UMC at around 20% more than a traditional VMC. Burton’s satisfaction was evident: “At only about 20% more than a VMC, this should essentially become a no-brainer.”

Technical Innovation:

The Roller Gear Cam System

Central to achieving both performance and cost targets was the adoption of a Japanese roller gear cam mechanism for the tilt/rotary table. Burton explained the technical reasoning: “We saw this table probably six years ago, and our partners built the actual table with the high-end Japanese parts in it. So, it has zero backlash and almost zero maintenance.”

This mechanism replaced the traditional worm and wheel or expensive direct drive systems. By using a cam that engages with rollers around the turret, the system achieves 30rpm rotation speeds on both B and C axes whilst maintaining zero backlash. The rolling mechanism reduces friction, allows enormous torque transmission, and crucially, helps keep costs manageable.

Burton was clear about the quality standards: “We’ve actually built the machine and tested it to the same tolerances as our 5X. We’ve still put it through our rigorous check sheets and tests, and it’s built to the ISO standard as well.”

Built-In Spindle Technology

Another significant technical decision was the adoption of a built-in spindle design, where the motor windings and spindle are assembled as one unit. This choice was informed by XYZ’s experience with their LTY-S sub-spindle lathe, launched last year.

The 400 UMC’s built-in spindle is chilled to reduce heat build-up, delivers 25.7kW maximum power, with continuous power of 11kW and duty cycle power of 18.2kW. The standard spindle speed is 12,000rpm with a 15,000rpm option available with a BBT40 face-and-taper configuration for enhanced rigidity.

Bridge Design for Maximum Rigidity

The machine employs a bridge-style construction rather than the gantry design of the UMC 5X. This means the X and Z axes remain absolutely static on the bridge, with only the cradle-style tilt/rotary table moving in the Y-axis underneath the spindle. The meehanite cast iron construction features an innovative honeycomb rib pattern, proven through testing to maximise material removal capability whilst damping vibration.

The compact footprint of 3,030mm by 2,340mm belies the generous working envelope of 800 by 600 by 510mm in X, Y and Z axes. Corbett suggested the space saving was dramatic: “I’d nearly go as far to say, compared to the UMC 5X, you get three for two. The space saving is around 25 to 30%.”

Future-Proofing with Upgradeability

Perhaps the most innovative commercial aspect of the 400 UMC is its upgradeability from 4+1 to full 5-axis simultaneous machining. Burton explained the practical reality: “It takes about three or four hours for us to do on-site. A lot of it is computer licences and software.”

This removes the difficult purchasing decision that often stalls potential customers. Burton elaborated: “If you’ve got a bottleneck in your workshop, because you’ve got a skill or space shortage, you can put one of these in and machine five sides in one hit instead of multiple operations.”

Automation-Ready Design

Recognising industry trends towards unmanned machining, the 400 UMC features both front and side doors. The side door specifically facilitates robot loading, with XYZ already having orders for machines with automation integration. Burton explained: “This product has been designed to future-proof the potential purchases. We know that a lot of customers might purchase this machine with automation in mind.”

Siemens Sinumerik One Control

The 400 UMC is fitted with the latest Sinumerik One control featuring a 22-inch touchscreen and NCU 1740 processor – 30% faster than the previous 840D system. Mark Higson, XYZ’s Applications Team Leader, described it as “the nicest control I’ve ever used.”

The control features haptic feedback on the feed and speed override rotary controls – they vibrate when reaching 100%, allowing operators to maintain focus on the cutting process. Standard features include ShopMill conversational programming and collision monitoring with a built-in machine model.

AI-Powered Productivity: Siemens ACM

During the unveiling event, the media were given a presentation of the Siemens Adaptive Control & Monitoring (ACM) suite by Mark Coombes from Siemens UK. The software uses machine learning to optimise cutting conditions in real-time, with typical cycle time reductions of 10 to 25% and ROI periods of around six months.

Where Next – The Management Perspective

The concluding Q&A session with Martin Burton provided insights into XYZ’s direction. Burton, who took the reins alongside Chris Hellier through a management buyout, emphasised continuity: “Business as usual. Nothing changed. The feel must not change within this company. We’re recruiting more service engineers, and we’ve got more people on the phone downstairs, because we can fix issues over the phone. The focus will always be after-sales and looking after customers.”

Stock Management and Expansion

XYZ maintains 300 to 400 machines in UK stock for immediate delivery, valued at up to £20m. Burton explained the challenge: “When we place an order for a machine, it’s probably about six months to delivery, so we have to think a minimum of 6 to 12 months ahead. We’ve also purchased adjacent land and are planning a 30,000sq/ft storage facility divided into three units. We’ll have the foundations in within the next six months.”

Market Outlook

Burton was candid about some industry forecasts predicting 8% growth: “We think there’s going to be a bit of a tidal wave that will eventually come, which is why having stock is quite key to us. Long term, I don’t think it’s going to be 8%, probably be 4 or 5%. The 8% growth forecast was supposed to arrive last November, we’re now 12 months on and we haven’t seen it yet.”

Burton identified Europe as a key growth area, with Poland showing promising results: “We are starting to see orders coming out of there now regularly. We are actively seeking distributors in countries like Italy to expand our European footprint.”

New products will continue at a steady pace, with Burton revealing: “There are going to be two launches next year, and it’s probably going to be two machines a year.”

The XYZ 400 UMC represents a strategic intervention in UK manufacturing capability. By achieving a price point that makes 5-axis machining accessible to a far broader market, whilst maintaining quality and offering future upgradeability, XYZ has potentially removed a huge barrier to adoption. Burton’s goal of bringing 5-axis machining to every machine shop in the UK may have seemed ambitious at the start of the day. The event answered my opening question of whether XYZ has removed the final barrier to 5-axis entry, I certainly believe it has.