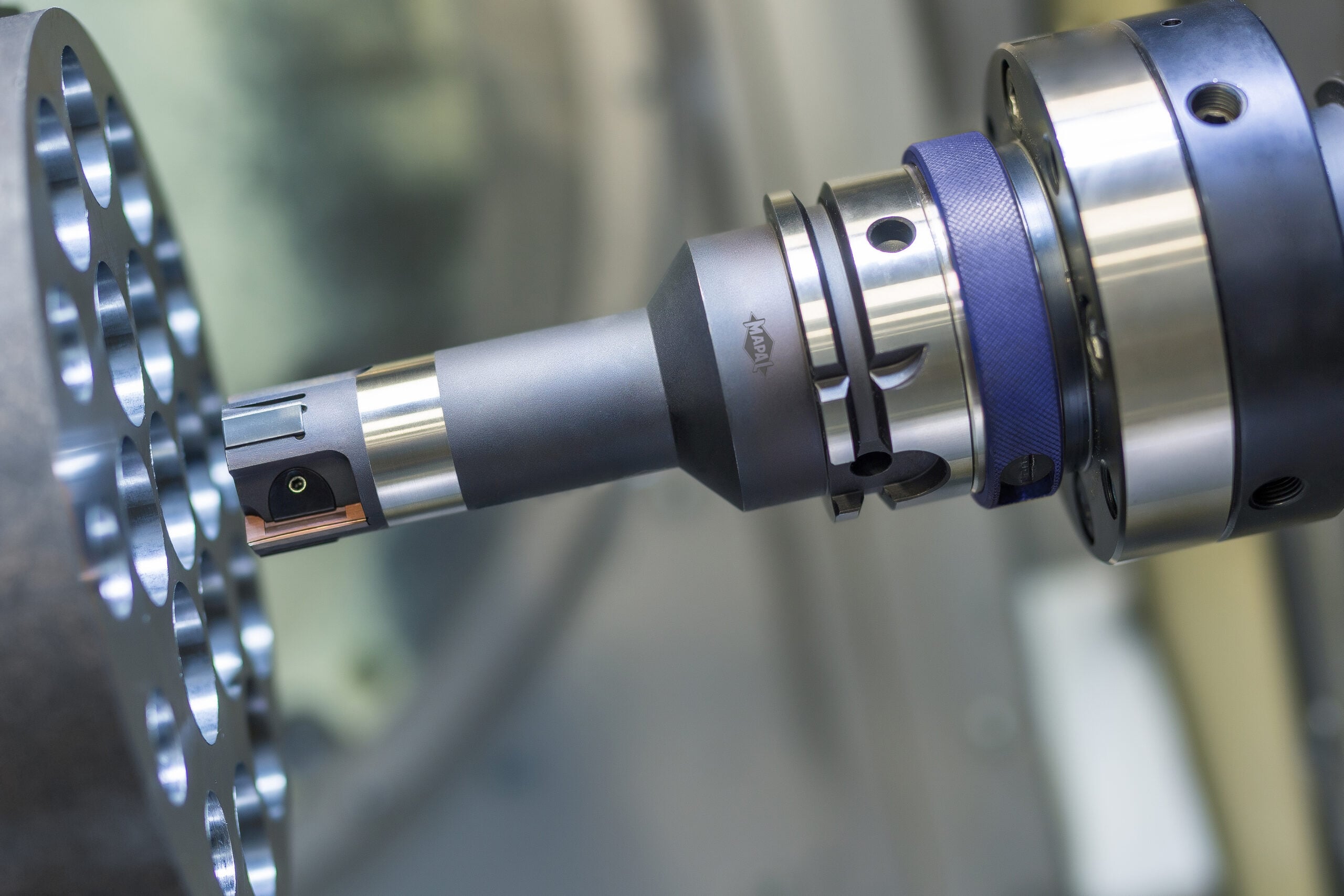

Mapal has developed a new, standardised chip breaker geometry for fine boring blades for machining long-chipping steel materials.

Chip formation plays a key role in process reliability, tool life and surface quality. So, Mapal has presented a brand-new approach to chip breaking for fine boring tools. It combines a precisely defined lead and rake angle geometry with optimally adapted cutting data and cutting depths. This adaptation enables chip formation, even for challenging materials. The result is optimal chip removal and reduced heat development.

Chip breakers are not a new invention, but the idea of implementing standardisation for long-chipping steel materials in fine boring is. The chip breaker geometry combines decades of experience in this area with a clear focus on cost-effectiveness and user orientation. Until now, Mapal has used chip breaker technologies for custom solutions.

The fine boring blades with chip breaker geometry for unalloyed, alloyed and stainless steels are now available from stock with defined geometries and coatings.