Baker has soft-spot for Lang-Technik

Founded in 2009 by Adrian Baker, Derby based Baker Engineering Ltd has rapidly grown to be a prominent subcontract manufacturer in the aerospace, rail, energy and power generation sectors with customers in the UK, Europe, the US and beyond. The company has gained a reputation for impeccable precision and quality that is the result of its investment in both staff and technology. MTDCNC visited Baker Engineering to find out a little more about both its investment and workholding strategies.

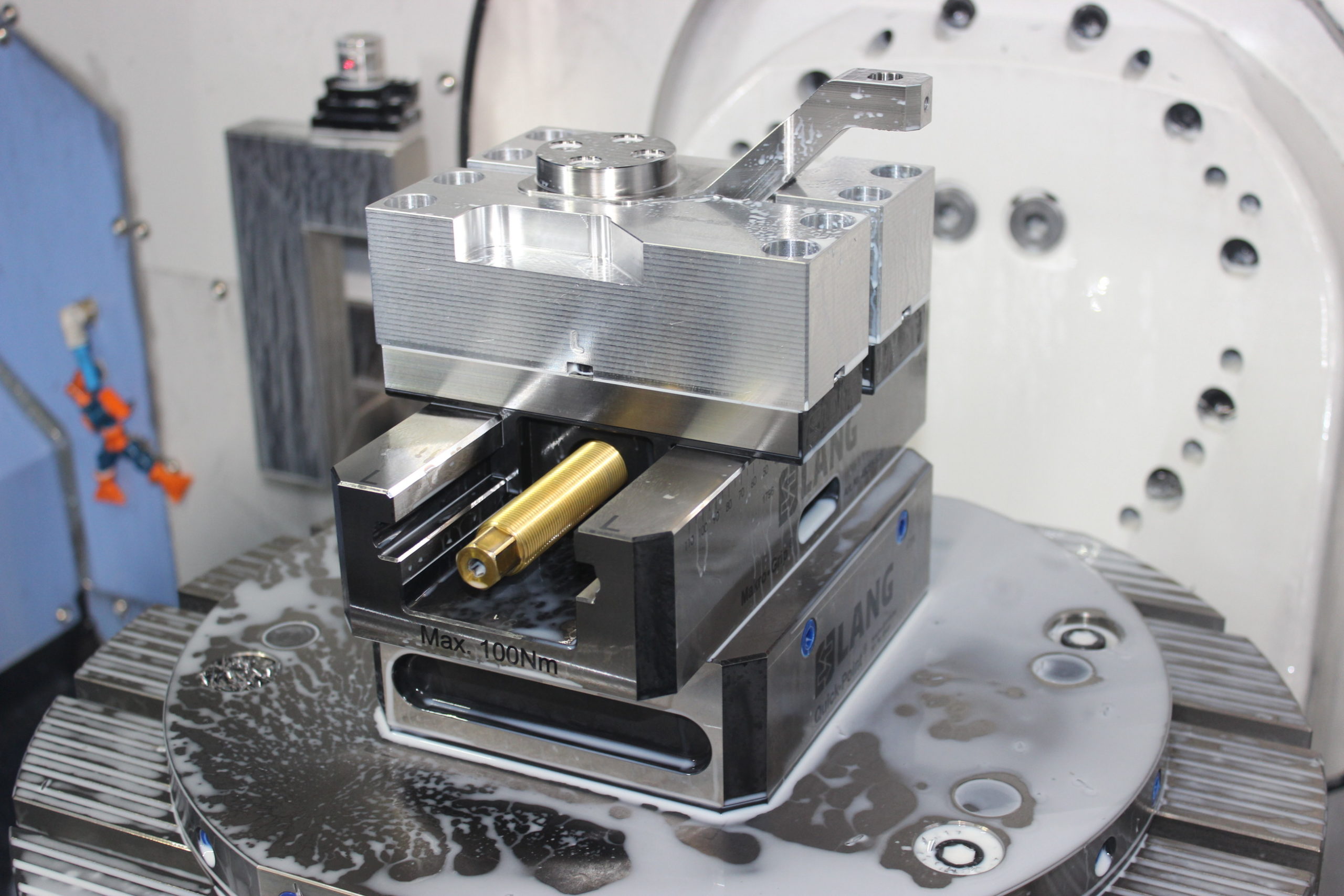

The company has a multitude of machine tool brands that includes Leadwell, Doosan and many others and it has recently invested in a new Doosan DVS 5000 5-axis machining centre and this has been complemented by workholding from Lang-Technik.

Speaking with Warren Baker at Baker Engineering, Warren tells MTD: “Our work ranges from one-off prototypes of jigs and fixtures right through to medium batch production.” Commenting upon the investment in the new Doosan DVS 5000 5-axis machining centre, Warren continues: “We have a good relationship and history with Mills CNC, so the acquisition of the DVS machine made sense to us as a business. We went to Lang for the workholding system and this combination was a very easy decision for us. Usually, we go through a list of suppliers and investigate the options, but Lang really is the company to go to. We’d been looking on the MTDCNC website and watching videos of installations at other companies, and that has really helped our decision process. We bought the system and we have been elated with the results we have achieved. It’s brilliant.”

Investing in the Lang-Technik Quick Point and Makro Grip system, Warren was asked what issues the company has had to overcome with its workholding. “We have had zero issues with the workholding, its perfect for 5-axis machining. Normally, you’d associate Lang with the stamping technology the company has developed, as it’s a great first-op workholding solution. We are using the Profilo system that is mounted on top of the Makro Grip vice. This allows us to machine in soft jaws with both first and second op components. The accuracy and repeatability is brilliant, it is within 0.02mm.”

Generally, the Profilo vices offer a simple and cost-effective solution to the problem of holding the component to then machine the sixth face once it has been machined on 5 sides using the MakroGrip jaws. The Profilo base jaws can fit onto existing Makro Grip vices enhancing the capability of the workholding system, as soft jaws can be purchased in steel or aluminium depending on the application, which is exactly the scenario at Baker Engineering.

“We also have the Quick Point system for zero-point clamping and this is something that we have now also adopted on an additional 4th axis machine. We have done this purely for ease of change over. Our changeover times have now drastically reduced and it has also helped to support us with retaining accuracy on all the components from one machine to the next.”

Commenting on whether Lang-Technik will be the workholding solution for the future, Warren says: “Now, I don’t think I would look anywhere else, to be honest. When it comes to vices and workholding, I will just go straight to Lang-Technik every time.”