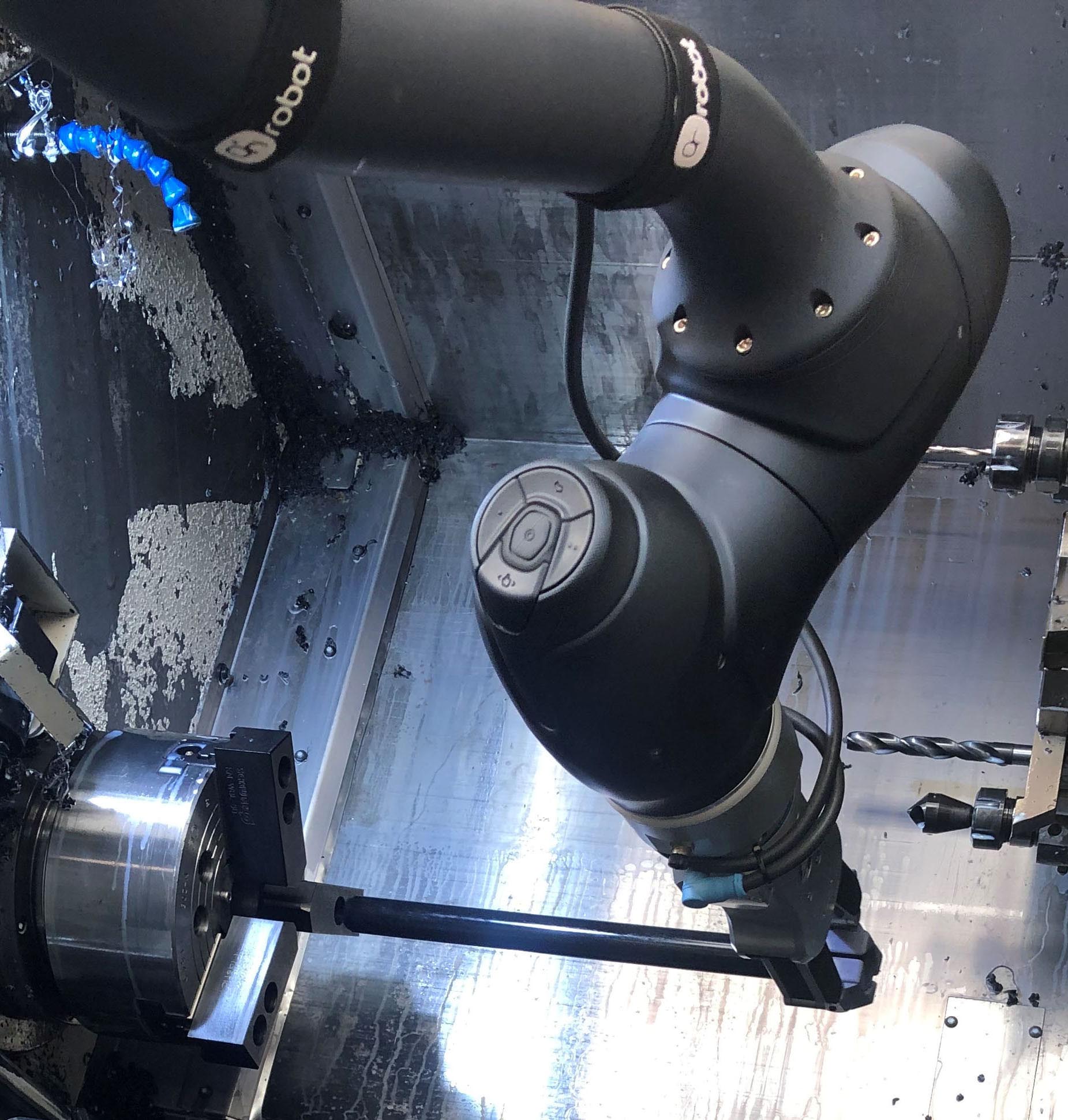

McCallum Bagpipes Ltd has recently acquired a cobot from Mills CNC Automation, the distributor of Doosan collaborative robots in the UK.

The M1013 cobot was supplied with RG6 OnRobot gripper end-effectors. It was installed in the company’s facility in February by Engineering Supply Co (Scotland) Ltd. The cobot was acquired to load workpieces that require machining into a CNC lathe and after the machining operations have been completed, unloading the machined parts into containers, and then repeating the cycle.

Says McCallum Bagpipes’ Managing Director, Stuart McCallum: “Since being installed, the cobot has improved operational efficiencies. By integrating the cobot with our Dugard Eagle lathe we can operate this machine 24/7.”

The automated machining of a medium batch of 100 practice chanters (bagpipe tubes) made from Polypenco plastic is placed in a pallet tray situated adjacent to the lathe and the cobot. Each chanter sits vertically in its own, individual circular hole – the cobot is programmed to open the machine door, take a chanter from the tray, orientate it and place it into the open chuck of the machine before moving away from the machine. The machine door closes and the chanter is machined. The cycle time including all cobot and machining operations is typically 3 minutes in total.

Explains Stuart McCallum: “We can load up jobs like this late at night during the 2pm – 12am shift. The 100 practice chanters are machined to completion overnight and unattended in approximately five hours. As well as getting five hours unmanned production from the machine, the cobot investment also means that operators are no longer required to perform repetitive and tedious part loading and unloading tasks.”

McCallum Bagpipes in Kilmarnock is on a strong growth trajectory with revenues and profits up, year-on-year, over the last five years. Whilst being good news for the company, the consistent upsurge in demand did put pressure on existing manufacturing resources. Explains Stuart McCallum: “Despite running a two-shift system, we were still under pressure. We needed to become more efficient and optimise the technology we already had at our disposal.”

The cobot has been permanently integrated with one of the company’s 20 CNC lathes and, after only two days required for its installation followed by a further two days to train four members of staff, the cobot was up and running.