Established in 1998 as a manufacturer of miniature precision, turned and milled screw machine parts from 0.2mm to 32mm diameter for high specification industries, Astec Precision recently wanted to embark upon machining larger components. With a range of sliding head turning centres from Star already installed, including a bank of SR-10J Type C machines, the Cumbrian company opted for another Star machine, this time the choice was the Star SX-38 Type-A.

Discussing the acquisition, Managing Director, Mr Eddie Young says: “At Astec Precision, we currently machine micro components and micro turned parts for the aerospace, medical, interconnect, energy and offshore sectors. There was a demand for us to make larger and more complicated components and this was the reason to bring the Star SX-38 Type A with HFT technology into our business.”

“The Star SX-38 gives us a bigger machine capacity, as before our largest machine was 32mm capacity. This machine gives us a 42mm diameter capacity and it allows us to machine longer parts that are more complex. It is also a more flexible machine than what we had before.”

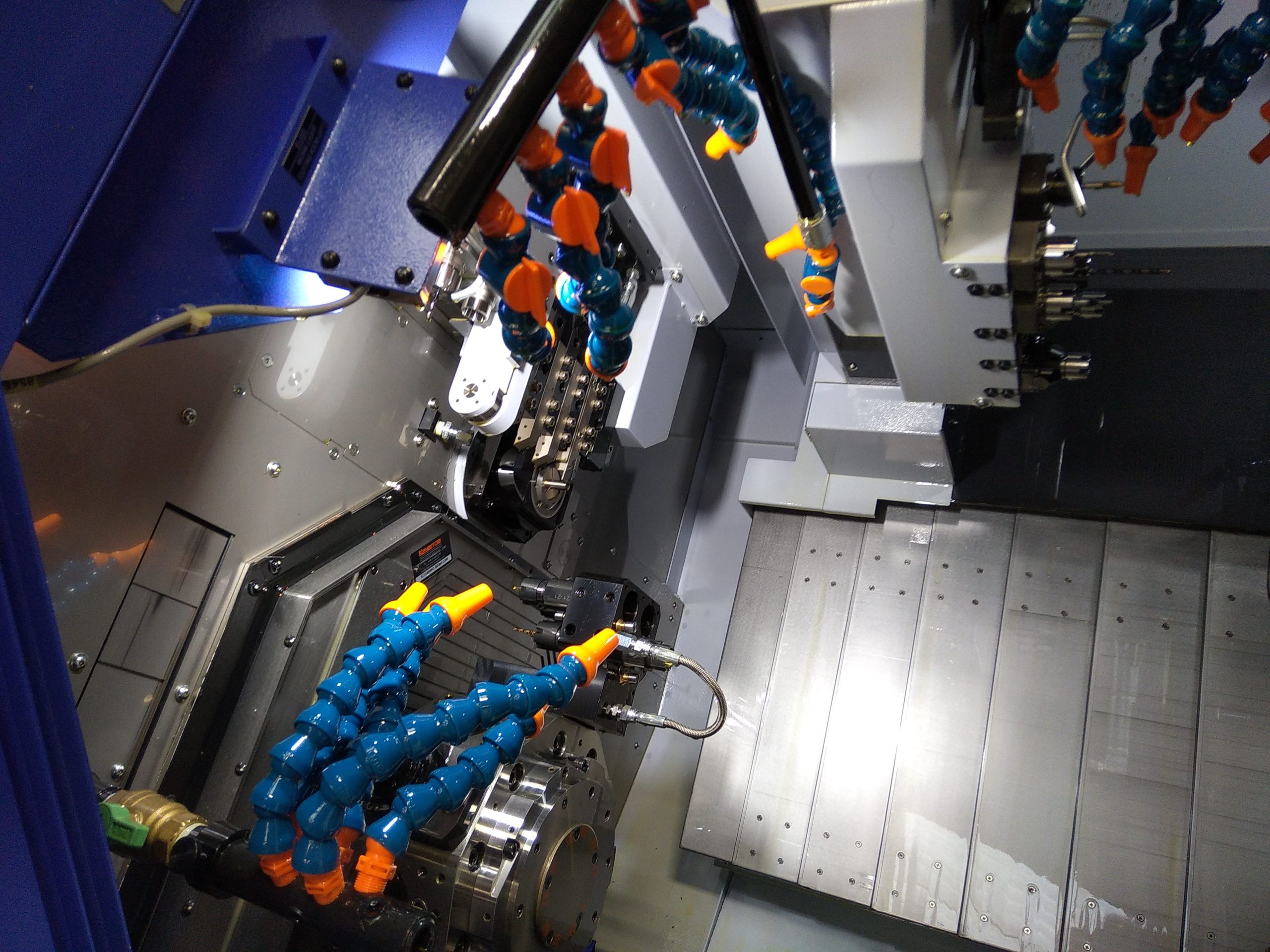

Taking a closer look at the machine and the process of understanding how to operate the new Star SX-38 Type A, Julie Emma-Fell from the Ulverston based company says: “It was a steep learning curve as this machine has three paths, but programming the new machine is certainly not an issue now.” Explaining the three paths, Emma continues: “On the head one, we have the tool platten with some driven tools and on head two you have the back turning tools for the sub-spindle and thirdly, there is the lower tooling turret that has multiple stations that can use driven tools, turning tools and drills on it.”

Commenting on what the robust new turning centre can accomplish in comparison to its predecessors, Emma says: “This machine gives us more flexibility on head two for machining on the sub-spindle – previously we wouldn’t be doing much more than drilling on head two. This machine has really opened our eyes to what we can do on head two. With the twin spindle and three tool turrets, there isn’t much that this machine cannot do. As a business, we are trying to get into machining more shell bodies and larger capacity parts. At present, we are machining larger and more complex parts out of materials like inconel and monel. One of the jobs on the machine is a prototype part for a customer that is being machined from monel – it has an 85mm deep hole drilled in it, and this would have been impossible to do on any of our other machines – especially as there are a lot of tolerances tied to +/-0.01 to +/-0.02mm.”

“Overall, I have thoroughly enjoyed learning how to use the Star SX-38 Type A machine. We have also had some interesting periods when we are using tooling turrets one and three at the same time for roughing and finishing and the tools are quite close together. The flexibility and productivity of this machine make it a great turning centre – I absolutely love using it,” concludes Emma.