Every machine on the Advanced Grinding Solutions (AGS) stand at MACH will be receiving UK debuts on their Stand 320 in Hall 17. AGS is showing the new Rollomatic 660XW GrindSmart multi-axis tool grinding machine along with Tschudin, Comat and FLP machines.

The latest Rollomatic machine combines the performance of a blank prep cylindrical grinder with the flexibility of a multi-axis tool grinder. The latest technology brings gains in production efficiency for tool manufacturers and the savings are made because lengthy setups on multiple machines are avoided. Typical production efficiency from the traditional multi-machine production method for standard end mills is in the region of 11% and this is increased to some 82% on the Rollomatic 660XW machine.

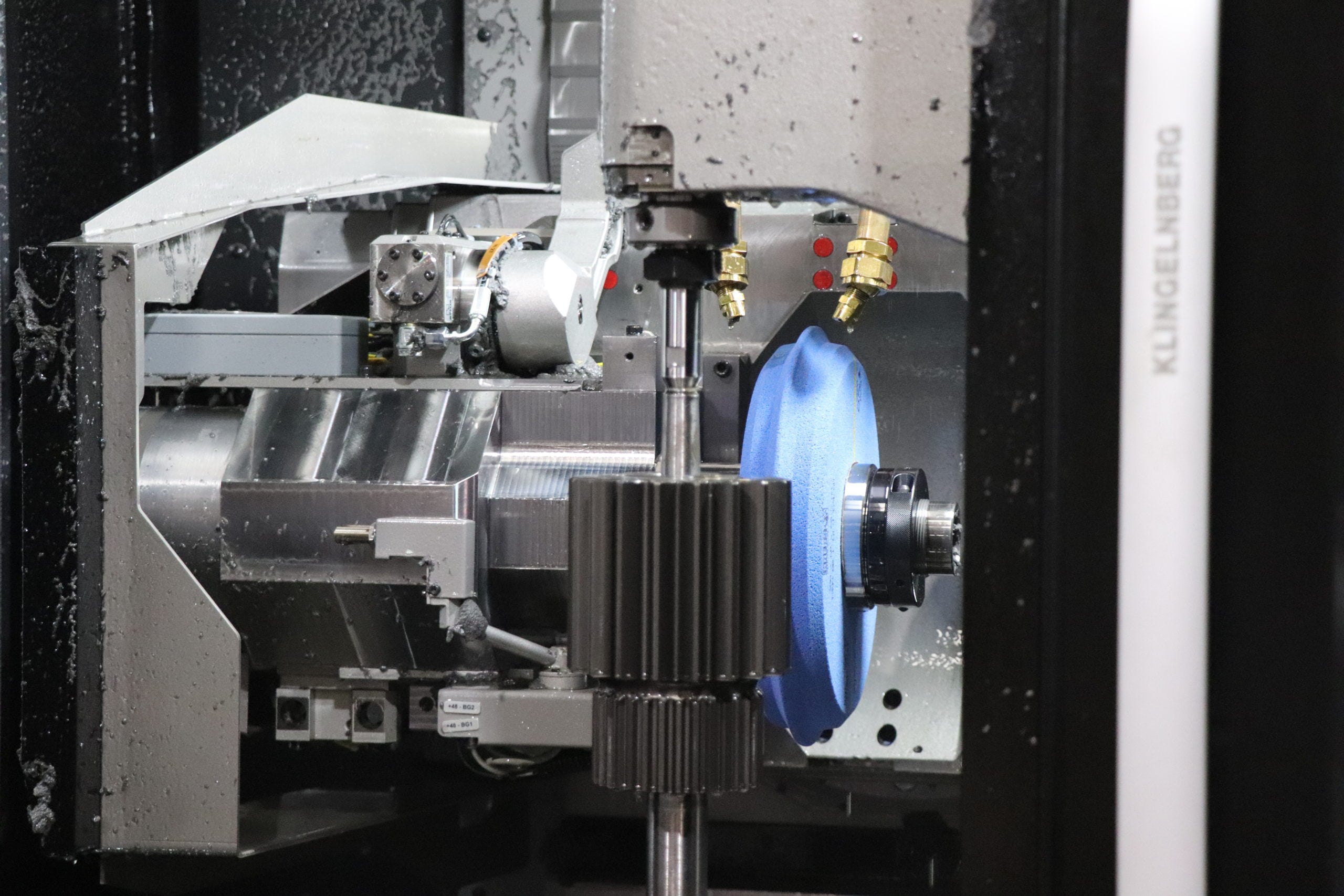

Also on display for the first time is the latest Tschudin Cube centreless grinding machine. The Tschudin Cube machine benefits from a new design that enables users to achieve productivity gains. The grinder can be manually loaded outside of the grinding zone and it uses Tschudins patented W-axis that has the workrest blade mounted onto its CNC axis that makes loading efficient, fast, and very safe.

Another UK debutant will be the Comat C-120 filtration system. Comat superfiltration systems are engineered to filter neat cutting oil to 2 to 3 microns whilst constantly maintaining a stable temperature (+/-0.2 degrees), without compromising filtration or flow rates. Comat superfiltration systems minimise running costs to obtain the lowest cost per litre of oil filtered. The C120 is the latest compact superfiltration system designed to manage a single machine tool and can filter any contaminant to guarantee intelligent performance with process optimisation by remote monitoring.

FLP (Fine Grinding, Lapping and Polishing Machines) are showing their new FLP380 single-sided lapping machine. The range of FLP machines also includes twin wheel – double-sided CNC lapping and fine grinding machines.

FLP Double Disc or twin wheel machines have seven machines in the range offering a working disc diameter of between 540mm and 1.3m. These can be offered with full automation via linear or robotic solutions, and weigh between 7 and 16 tonnes. These machines are offered as high-precision versions with granite machine beds and the latest machine controls.

Specialists from Krebs & Riedel will be present on the AGS stand to discuss all grinding applications and the best use of their range of internal and external grinding wheels. Krebs & Riedel manufacture high quality conventional, diamond and CBN abrasives and are constantly introducing new types of wheels with improved grain structures and novel bonding systems that enhance grinding wheel quality and optimise performance.