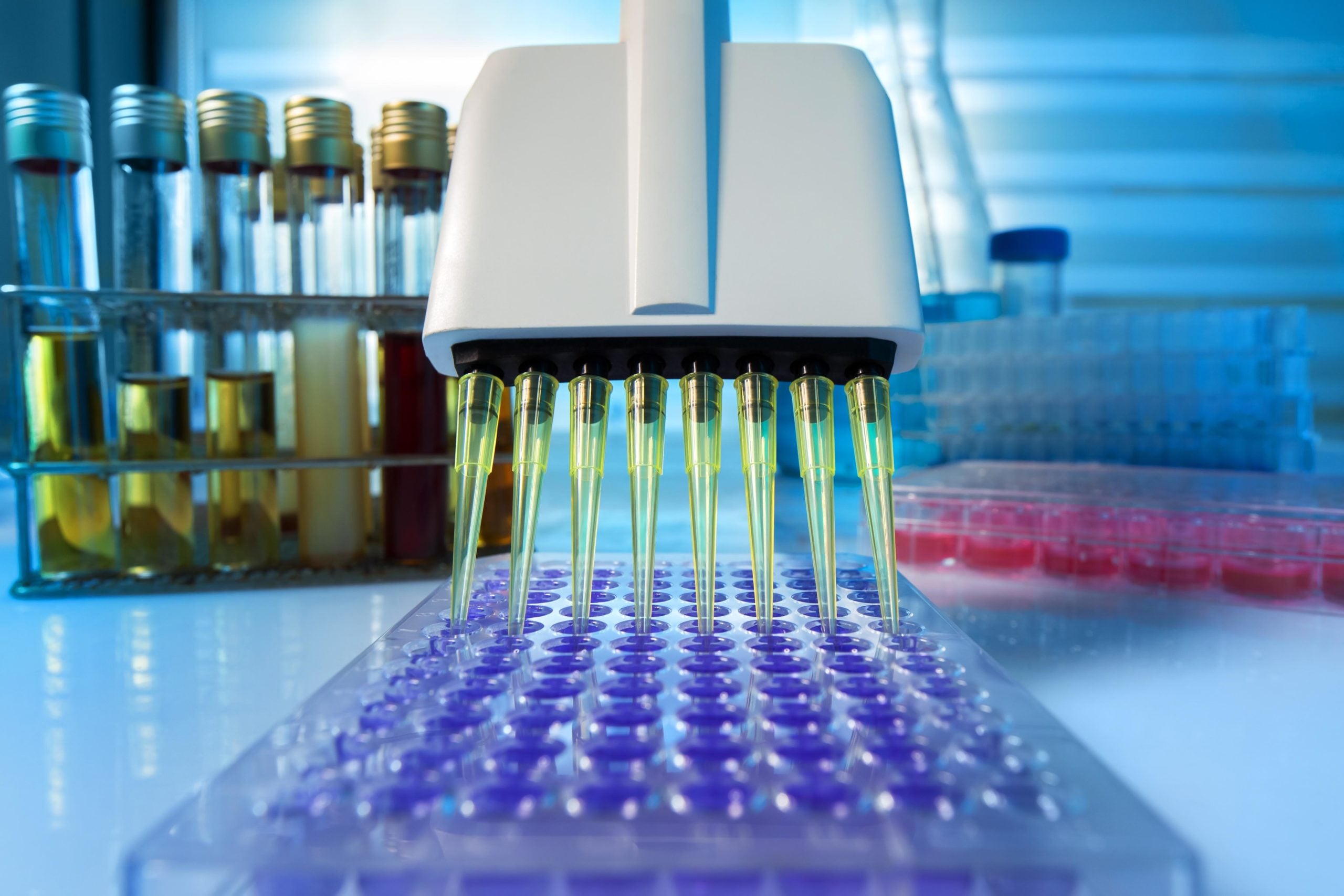

With more than 30 billion pipette tips used globally every year, the demand for the high-quality mould tools to manufacture them has never been higher – especially as annual growth stands at 8%. To support this growth, die-sink innovations from GF Machining Solutions are helping pipette tip mould tool manufacturers improve productivity, achieve consistent product quality and reduce operational costs.

Manufacturing these mould tools which, typically, have a multi-cavity design, involves significant time devoted to manual (hand) polishing to achieve the stringent surface finishes required. These difficult and time-consuming operations are performed by skilled technicians and, as such are expensive and can create production bottlenecks and often extend the time to market.

Little wonder then that mould tool manufacturers are looking for proven technologies that allow them to produce these high-quality tools more efficiently with reduced reliance on costly secondary finishing operations. GF Machining Solution’s advanced, robust and thermally-stable die-sink machines equipped with technical innovations such as the company’s iGAP technology and fast digital (Intelligent Power) generators provide manufacturers with a reliable, time and cost-saving solution.

Pipette tip mould tool manufacturing can be time-consuming.

Used extensively in the medical diagnostics, food and chemical industries, the pipette tip market is experiencing 7% to 8% annual growth and currently, the industry produces over 30 billion tips each year. To produce this volume of tips, it is estimated that 5,000 mould tools, equating to 100,000 hours of manufacturing time, are currently being used by manufacturers located predominantly in Europe, the US and the Far East.

But, with shortages being experienced across the world – it is reported that this is still not enough to meet future demand. It is anticipated that over 500 new mould tools, not including repairs to existing tools, will need to be manufactured every year.

It’s a tough ask, but it is against this backdrop that GF Machining Solutions (GFMS), the EDM, milling, laser and additive manufacturing machine tool specialist and automation and tooling system solutions provider can, with its EDM die-sink machines, offer some respite.

GFMS has a long pedigree in providing high-end machining solutions to medical manufacturers and it works in close collaboration with medical device manufacturers in designing and developing high-productivity turnkey and process improvement solutions for customers.

Concerning pipette mould tool manufacturing, the company’s recent technological advances made to its die-sink machines provide a way forward. This is particularly pertinent to the company’s iGAP and digital generator technology.

iGap technology

The iGap technology is an innovative feature in GF Machining Solutions’ advanced FORM-series of die-sink machines. It is an embedded auto-adaptive system that can respond to changing machining conditions by altering the discharge current and pulse duration in real-time, elevating cutting speeds and reducing electrode wear, especially lateral wear during roughing and finishing operations.

The system is most effective when using copper or graphite electrodes to machine mould tools with deep multi-cavities, using a spark gap of less than 0.2mm to deliver smooth, homogenous and repeatable surface finishes to VDI 0, reducing and in some cases even eliminating the need for hand polishing. The virtual elimination of secondary finishing operations enables pipette tip mould tools to be manufactured more quickly and efficiently than before with fewer electrodes and, as a consequence, reduced costs.

It is interesting to note that hand polishing just one square millimetre of the interior of a cavity can take up to 30 minutes. With deep cavities, the time required for hand polishing each cavity could be as much as 20 hours. This means that for multi-cavities, hundreds of hours could be required to achieve the desired ‘polished’ finish. iGAP technology is therefore a real asset for pipette tip mould tool manufacturers as it can boost productivity to ensure high and consistent surface finishes that will subsequently reduce overall costs.