A thread of success

In the highly competitive cutting tool industry, the majority of manufacturers offer a comprehensive range of quality solutions without necessarily being outright experts in one specific field. There are obviously some exceptions to the rule, but they are few and far between. As world leaders in threading, Vargus is one of the few and far between. Vargus has a 60 year pedigree in the niche arena of threading, so MTD Magazine spoke with Ori Ehrenberg, the Medical Industry Product Manager and Baruch Books, the Vice President for Sales, Marketing and R&D.

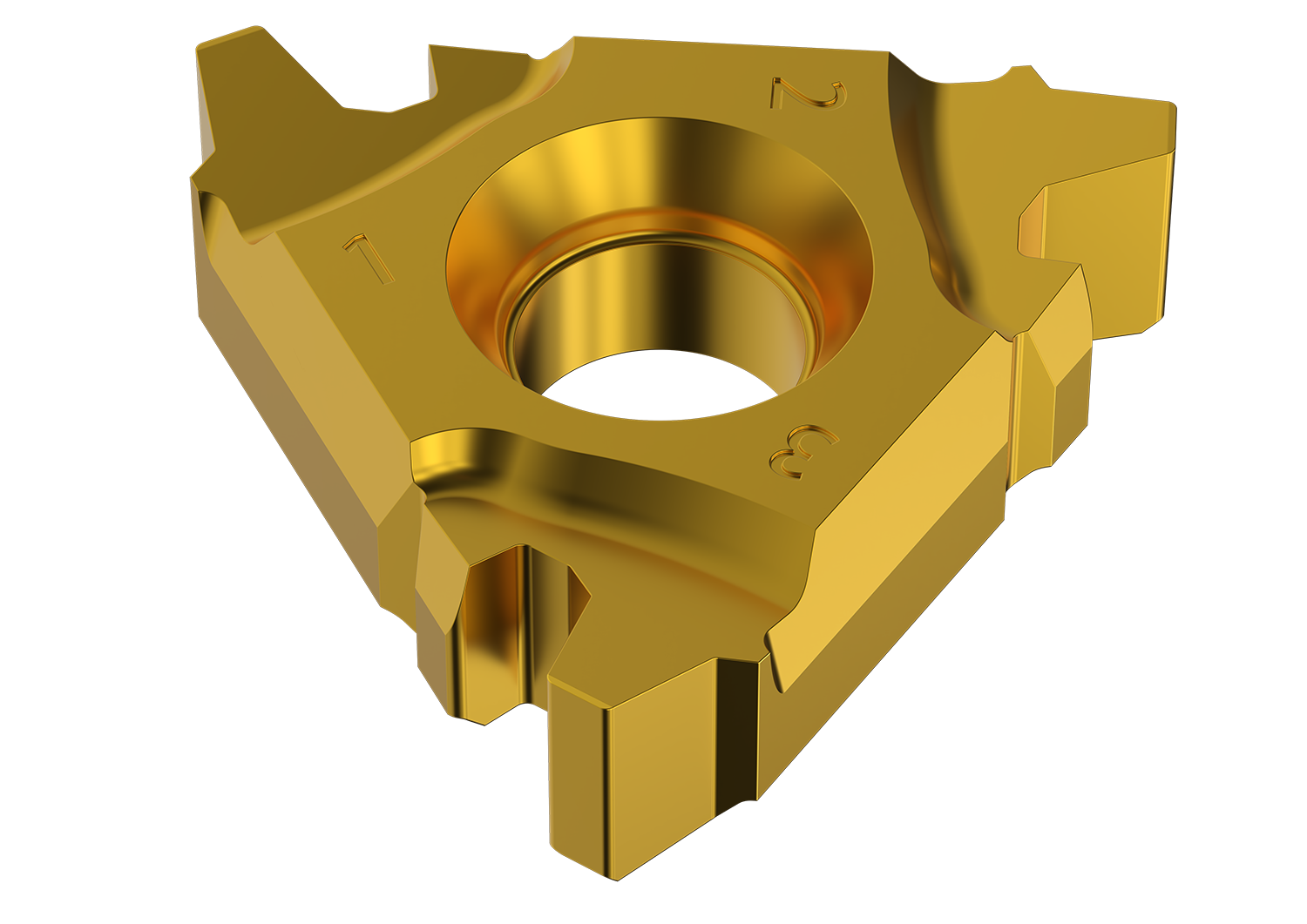

One of the first subject matters that was broached was the new MACH threading line that was launched back in January. The MACH Supersonic Threading range for Thread Turning and Thread Milling applications is a completely new innovation. Explaining the MACH line, Baruch Books says: “The MACH range was three years in development. As innovators, we lead and not follow, we are only competing against ourselves. The MACH series is a completely new method of generating a thread. We started from the ground up with new toolholder designs, insert geometries, coatings, substrates and so on. We didn’t want to improve on an existing product line. Our target was to improve cycle times by 70% and we achieved this. In the process, we have also massively improved tool life and surface finish. For instance, a thread that typically takes 10 to 12 passes can now be finished in three passes, and see dramatic improvements in tool life and surface finish!”

This example highlights how Vargus differentiates itself from other cutting tool manufacturers. In fact, in the last three years, the company has introduced more than 25 different product ranges. Baruch credits the investment in R&D: “We restructured our business model and have invested heavily in R&D in the last three years. We have doubled the number of engineers we employ, and we have invested significantly in machinery and other technology. R&D and engineering now account for 20% of our employee headcount, as an investment in people is the key to success. Our technical centre has six machine tools running 24/7, trialling and testing new tool developments, creating hundreds of kilos of swarf daily.”

Medical Excellence

With life expectancy extending through medical advances, the industry is a significant growth market for manufacturers of everything from prosthetics and implants to surgical equipment. Commenting upon this, Ori Ehrenberg says: “Average life expectancy has risen from 60 years in 1950 to over 80 years in Europe and North America. We are becoming more dependent upon implants and joint replacements as we live longer. As technology advances, there is a greater demand for more complex products and this creates more opportunities for manufacturers. However, like the automotive industry, the medical industry and its supply chain are looking for lower cost per part, shorter lead times and to reduce manufacturing costs without compromising quality.”

Adding to this, Baruch states: “This industry is going through rapid changes with the onset of technology like 3D printing of organs, valves and complex geometry prosthetics. Added to this, some countries have witnessed exponential population growth and this brings further demand for technological revolution. We have always strived to reduce production costs through new technological advances. What we are doing at Vargus is working with leading innovators in the medical industry, such as the academics, surgeons and researchers to provide solutions for the future demands of the sector.”

Expanding upon this point, Ori says: “There is a strong move towards implants now being 3D printed in different types of materials, especially in titanium, stainless steel and even composite materials. This, however, does not diminish the demand for threading applications since all implants require a screw connection.

“We have excellent standard solutions for stainless steel and titanium applications, which are extremely popular in this industry. And we are now working with a host of medical R&D facilities on how to create threads in composite materials without witnessing the common issues of delamination and poor thread quality. This is an exciting challenge that we are fully embracing. Every material has a different story and composition with the fundamental common attribute that it is very difficult to machine. We are developing threading tools with new edge preparation techniques to prevent delamination and also new methods of applying tool coatings to the substrate to prolong tool life and performance. Like everything at Vargus, this is a relentless pursuit of improvement that will never end.”

“Almost every implant requires a thread to attach it to the bone and the surgeon conducting the procedure has a multitude of standardised thread profiles to choose from. Whilst many cutting tool manufacturers try to be full-line suppliers, the unique applications demand extremely technical solutions and Vargus is one of the very few cutting tool manufacturers that can accommodate this. Not only are we the biggest threading tool manufacturer in the world, but we are also breaking boundaries with our R&D. Whilst the technological evolution of the medical industry exponentially expands, we are already advancing technologies with the leading medical companies and research facilities for the next generation of advancements,” adds Ori.

Looking at some of the challenges faced by the industry, Baruch says: “Every industry faces the same challenges of increasing operational and material costs as well as the pressure to deliver more bespoke products at shorter lead times with reduced cost-per-part requirements from customers. We recognise these concerns and we have created solutions based on the issues that manufacturers face. For example, we worked with machine tool manufacturers to introduce our thread whirling system to increase productivity and reduce costs and set-up times drastically – incorporating features like multiple start threads. With regard to additional applications such as groove-turn, front and back turning, and parting off, we addressed the issue of material cost and worked to strengthen and enhance our solutions. For example, for parting off tools such as our ST-Cut and VG-Cut, in our GROOVEX – Grooving and Turning Line – we lowered the parting off width dramatically. Our parting inserts offering once started at 3mm width and have decreased to 2mm, then 1mm and now as low as 0.5mm. Where we have differed from other manufacturers is that we have retained the performance, productivity, strength and tool life of our tools. This may seem a small incremental move, but saving over 2mm of waste from each part manufactured from a bar can have a huge impact over a week, a month or a year – saving the customer thousands in material costs.”

“In addition, we have a wide range of internal micro-machining solutions in our micrOscope Line, specifically designed for the medical and dental industries. We are now able to machine inside holes less than one millimetre in diameter.”

Looking to the future, Baruch concludes: “I believe we are the most interesting company with the most diverse and innovative solutions for industry. We create the technology ourselves and always develop unique product lines. Our heavy investment in R&D will help us to continue at a rapid pace. It is easy to copy somebody else’s methods and follow in somebody else’s footsteps, but at Vargus, we are committed to leading the industry, not following. This is how we break new boundaries and stay ahead.”