🎧A pilot drill that’s up to any challenge

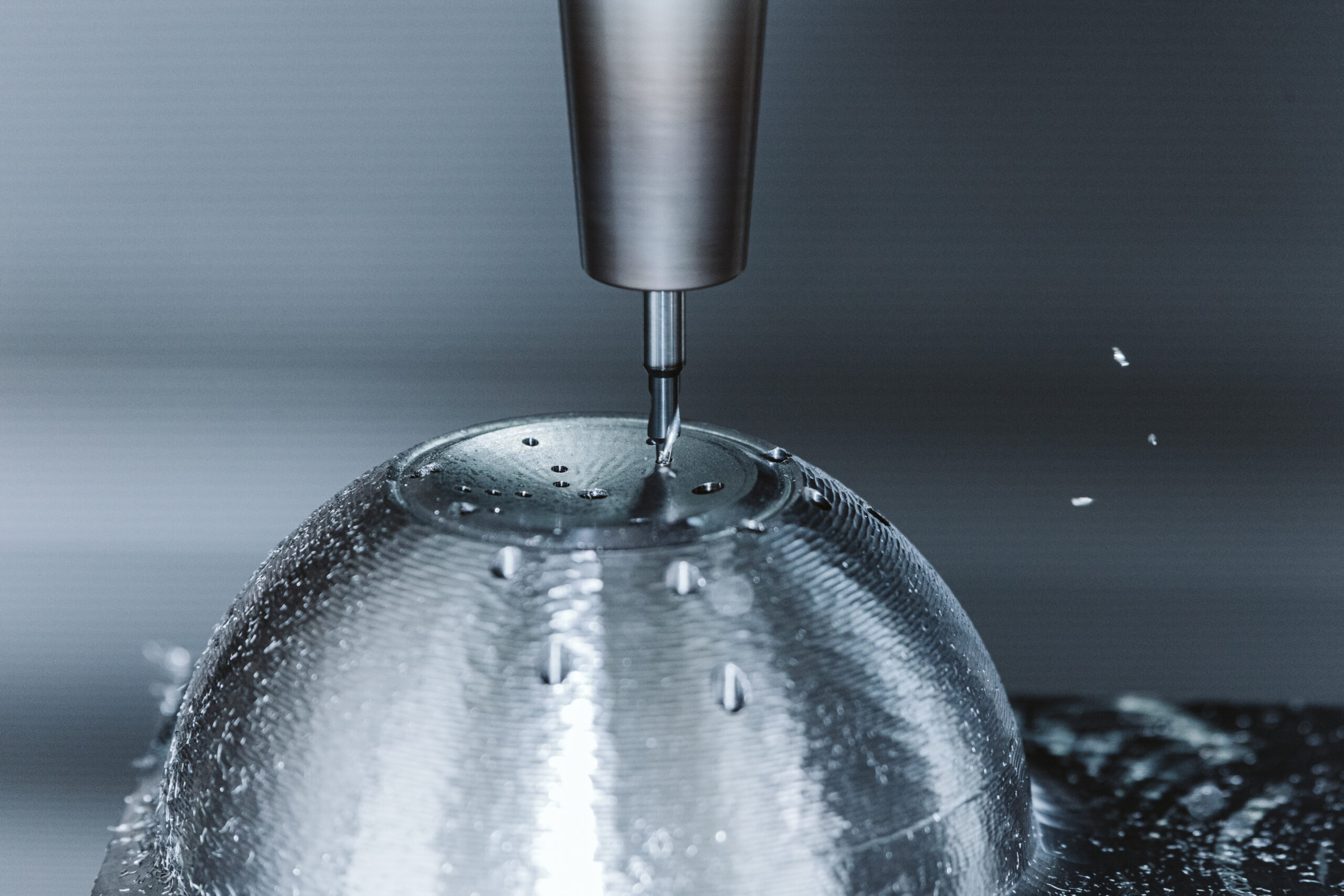

Manufacturers could only drill on inclined or curved surfaces with pre-chamfering using a milling cutter in the past. Those days are now behind us and you only need one tool – the newly developed WTX Micropilot from CERATIZIT. It can even pull off 90° countersinks at the bore entry in a single operation —saving tool changes, cycle time and costs.

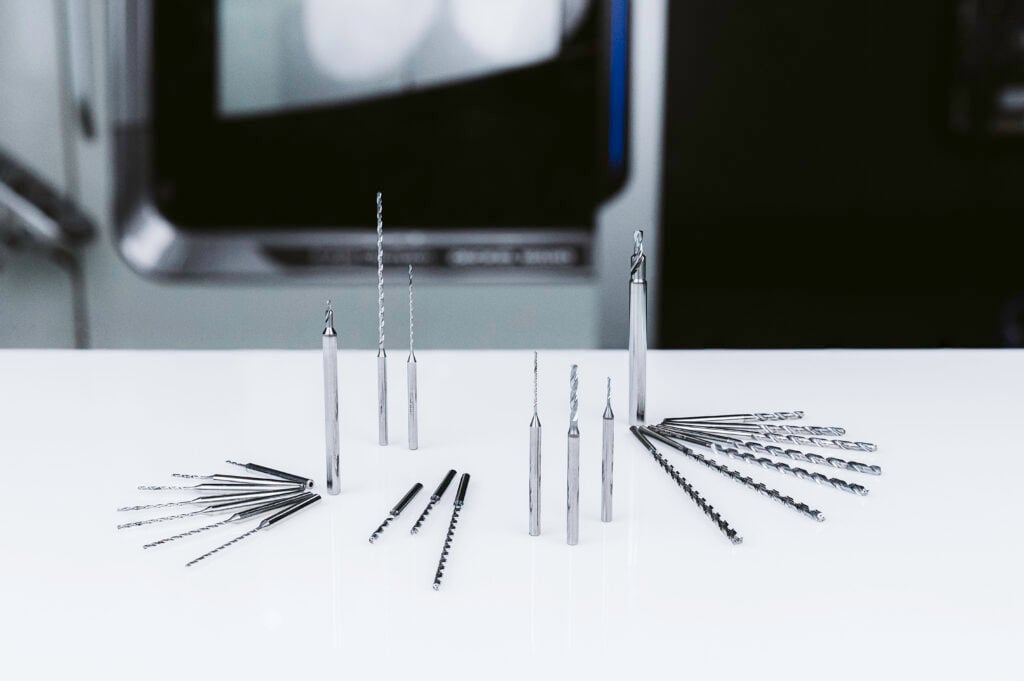

Micro machining has rules and practices that are different to everyday machining. Simply put, what works well with standard tool dimensions does not necessarily hold true with small diameters. “To this end, we have revised our micro drilling program and developed a genuine time saver. The WTX – Micropilot is small in stature, but big in performance. Perfectly matched to our WTX – Micro micro drill from 8xD to 30xD, the pilot drill is used at drilling depths of up to 2.5xD,” says Manuel Keller, Product Manager at CERATIZIT.

When faults occur in complex, micro-sized components, they quickly end up dumped in the recycling can. The truth is that a number of things can go wrong. Drills can run off, drill holes get crooked or tools break—including damage to the workpiece itself. “Efficient machining of small components presents its own set of challenges,” says Manuel Keller. “Our customers want process reliability, the shortest possible machining times and demand extremely high-quality standards. Fortunately, our WTX – Micro series is up to the task.” Thanks to its ingenious face geometry with a 160°-point angle, the tool ensures the follow-up drill can plunge in cleanly and without running. And with the special Dragonskin coating, clean chip removal and a longer tool life are guaranteed.

The WTX – Micropilot is developed from the latest technologies from the substrate to the geometry to the coating. It is also perfectly designed to work together with its ‘best buddy’ WTX – Micro. This drill duo can handle the most common as well as the most demanding tasks. “One special feature of the WTX – Micropilot is that it circumvents the usual mirroring required if drilling inclined and curved surfaces with an inclination of up to 50. This eliminates one processing step, saving time and tool changes. When piloting on straight surfaces, a 90° countersink at the bore entry is also possible,” reveals Manuel Keller.

What all WTX micro drills have in common is their special pointing. This maximises positioning accuracy and excellent centring properties. Their lapped surfaces and the patented chip space grinding also guarantee safe and fast chip removal. Additionally, the spiral internal cooling channels of the WTX Micro drill have been optimised to ensure maximum flow of cooling lubricant, which, in turn, secures improved surface quality of the holes. Among other things, this is thanks to a power chamber, which is fitted to the micro drills from 5xD over the entire shank length, which increases the amount of coolant at the tip while maintaining uniform pressure—thus improving tool life.

Made for maximum precision

With its micro-tool portfolio, CERATIZIT covers most micro-machining applications with high-quality solutions. “This also applies to the WTX – Micro product range, including the new WTX – Micropilot, which makes the impossible possible. On both inclined or curved surfaces with an inclination of up to 50°, there is no need for prior mirroring. And if 90° countersinks are required at the bore entry point on straight surfaces, WTX – Micropilot can easily handle the task in a single operation, saving tool changes, time and costs—without sacrificing quality,” says Manuel Keller.