5-axis DMG Mori is a Diamond

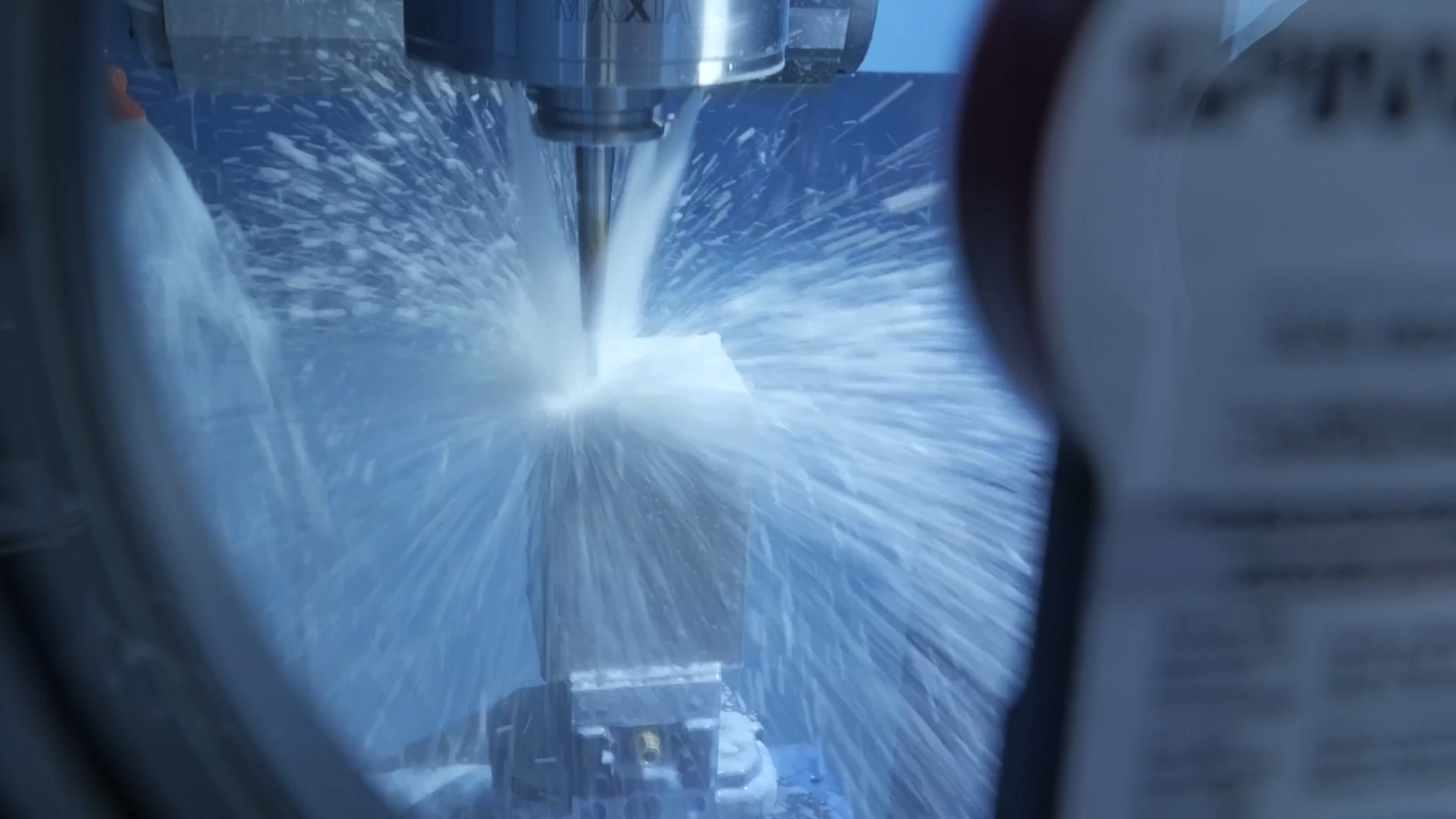

With a history that dates back more than 50 years, Blue Diamond Engineering Ltd has just invested in its first 5-axis machining centre, a DMG MORI DMU 95 monoBLOCK. MTDCNC visited the Shildon based company to find out why? The County Durham based SME started out servicing the mining industry and has since diversified into the steel, oil & gas, nuclear and machine-building industries. Jonathan Hedley, the General Manager at Blue Diamond Engineering says: “The previous machines we’ve had with 5-axis have been positional whereas the new DMG MORI is a full simultaneous 5-axis machine. This gives us the ability to machine swept features such as that you see on turbine blades. This capability is allowing us to move into the automotive sector and increase our work in the energy and medical sector that we already service.”

With a history that dates back more than 50 years, Blue Diamond Engineering Ltd has just invested in its first 5-axis machining centre, a DMG MORI DMU 95 monoBLOCK. MTDCNC visited the Shildon based company to find out why? The County Durham based SME started out servicing the mining industry and has since diversified into the steel, oil & gas, nuclear and machine-building industries. Jonathan Hedley, the General Manager at Blue Diamond Engineering says: “The previous machines we’ve had with 5-axis have been positional whereas the new DMG MORI is a full simultaneous 5-axis machine. This gives us the ability to machine swept features such as that you see on turbine blades. This capability is allowing us to move into the automotive sector and increase our work in the energy and medical sector that we already service.”

“The DMG MORI DMU 95 monoBLOCK has reduced operations and increased the potential for finishing jobs in a single set up. There have been times when we have done a job on a 3-axis machine and there have been up to 10 operations in a single job. Now, providing we put the time upfront in creating a fixture, we can reduce that to 2 or 3 operations. It also enables us to improve the accuracy of the components we machine. This is because every time you set a job up, there is an increased potential for error.” Commenting upon why the company opted for the DMU 95 monoBLOCK from DMG MORI, Jonathan continues: “DMG MORI has a reputation for quality and reliability. They also took us to see one of the machines and give us a demo on it. When we took the brochure back to our office and reviewed it thoroughly, we recognise that specification was excellent and the machine would fit nicely into our business and the kind of work we do – as well as where we would like to get to in the future.”

The machine is equipped with a 56 position ATC and the Speedmaster spindle system. Referring to this, Jonathan continues: “With a 56 position ATC, it gives us a lot of space for standard tools. The machine also came with the Blum tool measuring system, so tools are calibrated automatically. We also purchased a machine with an increased accuracy package. We now get linear accuracy of 5µm and on the old machines the best we had was 10µm. The machine also has the Heidenhain control with the Celos system, this is beneficial as we already have several machines with the Heidenhain control system. This makes a lot of our operators familiar with the system and even though we can programme off-line, the Heidenhain CNC is very friendly for the shop floor staff to use.” Concluding on the installation and subsequent support from DMG MORI, Jonathan says: “The service and support have been second to none. The machine arrived on time and with regards to sighting and installation, we were pretty much able to keep running our machine shop around their engineers when they were fitting the machine. They then came in and did a week of training with three of our guys; not just going through the machine specs but also how you use all of the features on the machine.”

The machine is equipped with a 56 position ATC and the Speedmaster spindle system. Referring to this, Jonathan continues: “With a 56 position ATC, it gives us a lot of space for standard tools. The machine also came with the Blum tool measuring system, so tools are calibrated automatically. We also purchased a machine with an increased accuracy package. We now get linear accuracy of 5µm and on the old machines the best we had was 10µm. The machine also has the Heidenhain control with the Celos system, this is beneficial as we already have several machines with the Heidenhain control system. This makes a lot of our operators familiar with the system and even though we can programme off-line, the Heidenhain CNC is very friendly for the shop floor staff to use.” Concluding on the installation and subsequent support from DMG MORI, Jonathan says: “The service and support have been second to none. The machine arrived on time and with regards to sighting and installation, we were pretty much able to keep running our machine shop around their engineers when they were fitting the machine. They then came in and did a week of training with three of our guys; not just going through the machine specs but also how you use all of the features on the machine.”