When Markforged launched onto the market in 2014 it caused a bit of a stir. A small start-up at the time, it debuted a process to rival other desktop 3D printers with its ability to print in continuous carbon fibre. Its first printer – Mark One – set the precedent for the range that was to follow but always with the same mission of producing extremely high strength parts very quickly and cost-effectively.

In just seven years, Markforged’s printer range has expanded in both size and capability. With the ability to print extremely stable and high-quality parts in over 11 printing materials including metal; the printers are being used in varied applications and in a range of settings, including CNC machine shops. Here users are reaping the many benefits that can be gained from adding this complementary technology to their portfolio of traditional machines.

For instance, West Midlands-based Rushworth Performance, a supplier of comprehensive pre-fabricated and bespoke solutions for the automotive, motorsport and engineering sectors, invested in a Markforged 3D printer three years ago.

“At the time we already had what can be classed as a hobbyist style machine and we could definitely see the potential in investing in a more commercial printer for our shop floor. Having seen the Markforged demo parts from Mark3D, we were immediately impressed with the quality and price range of the printer,” admits Matt Johnson, Managing Director of Rushworth Performance.

“Originally, the main product we pushed with the machine was an airflow housing part which was challenging to machine and would have required bespoke workholding. The beauty of the Markforged machine is that we could continually improve the part based on feedback from our customers. We did about 11 revisions of the part – tweaking the design in CAD and sending it to the printer – before settling on the one we sell today,” he adds.

As Rushworth Performance confirms, it certainly proves more cost-effective using a 3D printer rather than a CNC machine for such high value, low volume parts. And this is just one of many reasons why Mark3D is encouraging other machine shops to invest in a Markforged 3D printer.

As a solus reseller, Mark3D exclusively supplies, installs and supports the full range of Markforged printers as well as the printers’ print materials, software and accessories throughout Europe in offices based out of the UK, Germany, Benelux, Switzerland and Austria. As well as its expertise in the machines, Mark3D’s team also prides itself on its proven background in CAD and engineering.

“As a team, we put a lot of time into understanding the engineering angle,” says Ian Weston, Managing Director of Mark3D UK. “We are not a commodity shop, we base our sales on our engineering skills and knowledge of customer applications.”

While a percentage of these customers are from a machining background who are thinking of investing in a 3D printer for the first time, he is very quick to point out that a Markforged printer is just another technology to add alongside the machinery already in-house. It’s a complementary technology, not a replacement, with a host of reasons why it’s worth the investment.

“Just taking infrastructure as an example of a few of these reasons – unlike machine tools that are big, often have to be bolted to the floor and need three-phase electricity, a Markforged printer sits on a desk, is powered by a 240-volt plug and uses as much energy as a 100w light bulb. It will print parts that are stronger than aluminium with no coolant or swarf. With a 3D printer, there is also no programming and complexity is free in that the end-to-end production cost is in no way affected by a part’s complexity,” describes Weston.

While aware of many of these reasons, Leeds-based Kirkstall Precision Engineering, which for over 30 years has been providing turn-key solutions to a wide range of global clients, took a more considered approach to investing in a Markforged printer. Having researched the market and narrowing its selection down to three suppliers that all produced various trial parts, Kirkstall were most impressed by the quality, strength and competitiveness of the parts produced on Markforged and so decided to go with that.

Having installed the printer four months ago, Kirkstall’s Managing Director, Adam Thornton, was very impressed at how quick it was up and running. “On the same day we installed the printer we printed a customer product, and the very next day we were fully operational with it,” he says.

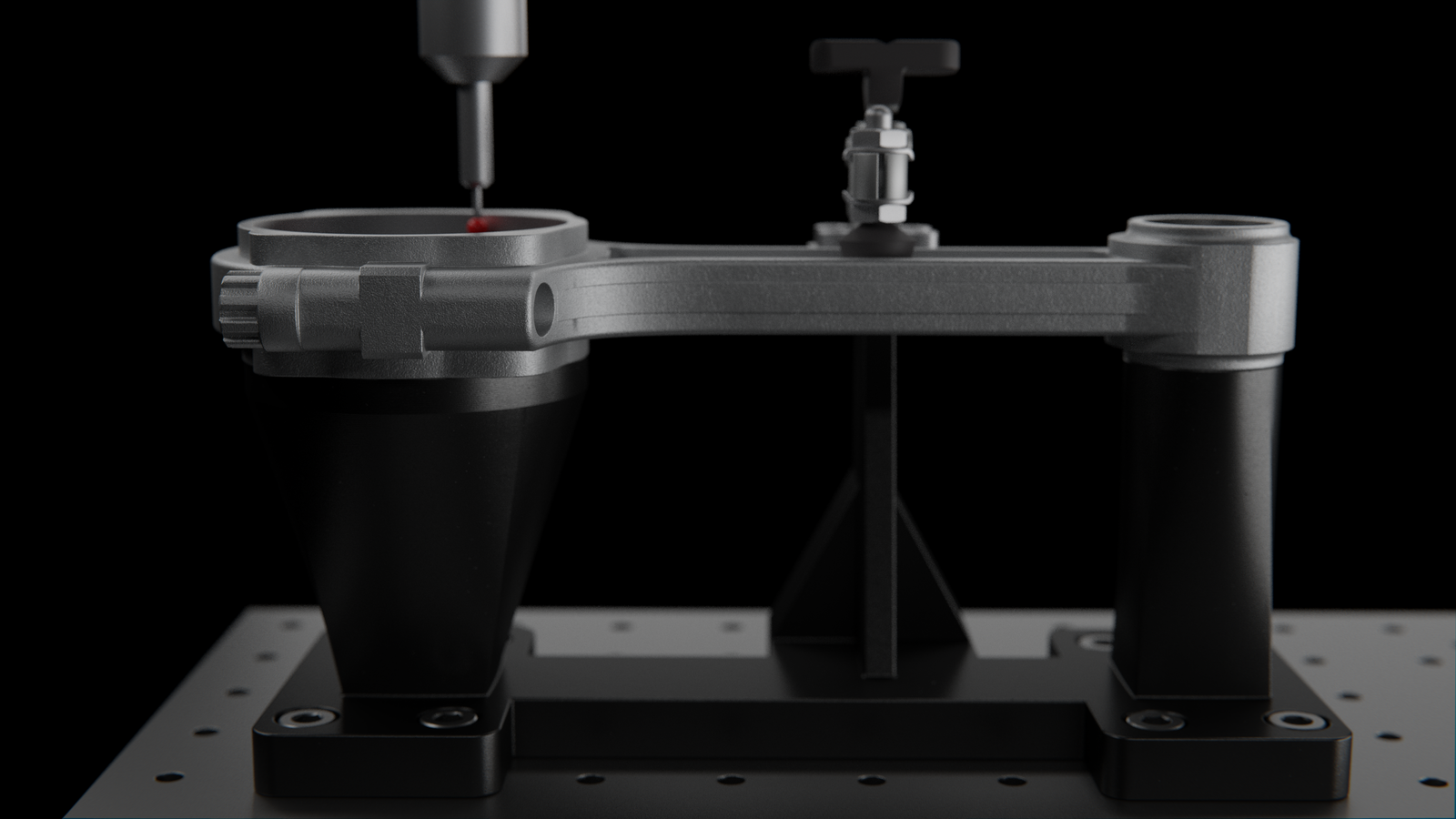

Currently, Kirkstall is predominantly using its Markforged printer to produce jigs and fixtures, which, according to Mark3D, is one of the main uses of the machines as the technology can be used to support production lines. For instance, instead of tying up expensive assets to make their own fixtures and workholding, they can print it quickly and far more cost-effectively.

“All the jigs and fixtures that our Markforged printer is currently producing we would have had to schedule them in our machine shop. So it’s not only taken time out of the machine shop, and so enabling us the capacity to be able to manufacture customers’ products, but we’ve also been able to create more innovative jigs and fixtures because of the capability of printing,” says Thornton.

“In terms of the strength, the ability to add reinforcements makes them extremely strong and, if you correctly designed the jigs, they will perform as good as a machined jig,” he adds.

Likewise, Rushworth has also used its Markforged printer to produce jigs, fixtures and work holding. “The beauty of it is I can reverse engineer off the final part in CAD, send it to the printer 5pm on a Friday and 9am Monday morning I’m pulling the jigs and fixtures off the printer to mount in the CNC mill or lathe,” says Johnson.

“As an example, we did a job about a year ago for a customer that needed a batch of 150 fairly simple, high-end stainless steel pig nose fittings. We literally printed the plastic jaws overnight, fitted it to the mill the next day and they produced the batch without skipping a beat. As with all our jaws and fixtures, if printed in the right orientation and in the right way there is no distortion in the jaw and you can go to town with it,” he adds.

As both Rushworth and Kirkstall will concur, the orientation in 3D printing, which is the alignment of an object within the space of the build volume, is crucial. This does not make using a 3D printer complicated, it is just something that users must bear in mind as it’s a different mindset. If anything, using a 3D printer is arguably far easier than using other production machinery. For instance, there is minimal programming, no tool paths to consider, no thoughts about fixturing, tooling offsets or collisions either. “If you can run CNC machine tools you can definitely run Markforged’s EIGER software. The process is as simple as putting the file in, it loads it, it prints it and that’s it. I can’t fault it – it just cracks on,” says Johnson.

If there are issues, it’s often down to user error rather than machine error. “We have printed a lot of jigs that haven’t quite worked out but that’s not down to the quality of the printer it’s down to us and our experience with printing especially in terms of orientation – the printer is more than capable,” says Thorton.

Of course, if there are any issues then they can always get in touch with Mark3D for support, which they both have done from time to time. “The support I’ve had over the last three years has been second to none, nothing has ever been too much of a hassle for Mark3D if I’ve needed help with anything,” admits Johnson.

Both Rushworth and Kirkstall are huge advocates of Markforged’s printers and encourage others to get in touch with Mark3D if thinking of investing in one themselves. As well as the reasons mentioned above, there are many others too. For instance, with a low entry-level cost the ROI is quick, readily found and sustainable. There are no operator costs as the printer can run day and night unattended. If needed, you could print from anywhere in the world. This could be advantageous if your team operates across various offices. All you need is the Markforged printer to be connected to Eiger. Lastly, spare parts for Markforged printers are a lot cheaper compared to those for machine tools.

“An argument I’ve come across in the CNC sector when it comes to purchasing a 3D printer is ‘if it ain’t broke why fix it?’ They also think that a 3D printer will put staff out of work. But it won’t. You will be giving the CAD team some more to do and you are making the tool setter’s life easier to literally up the process,” says Johnson.

“We use our printer constantly. It has run near enough non-stop for the three years we’ve had it. It can be left totally alone for as long as four-day prints. It just gets on with it,” he adds.

Kirkstall has only had its Markforged printer for a few months, but like Rushworth, they are already looking at expanding their use into creating one-offs and low volume end-use parts to offer new or additional services to customers. “Due to the accuracy, quality and strength of the 3D print, we are already producing some end-use products for our customers that have worked very well and have drastically reduced cost, lead-time and have increased performance,” says Thornton.

“We can certainly see some products that we could produce that will enable us to offer our customers a much more competitive solution. In the future, we may even expand our use further as I know that Markforged has been very successful recently in metal printing and that’s something that we’ll certainly be keeping an eye on as well.”