Common Issues

- High manufacturing cost of new product.

- Low manufacturing efficiency.

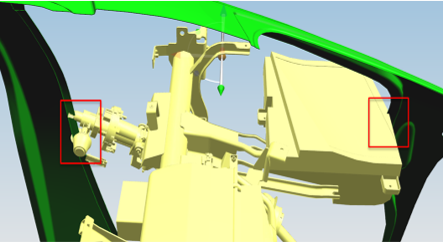

- Late identification and resolution of design issues

Common Causes

- Product design not challenged enough.

- Product design not supported for DFMA

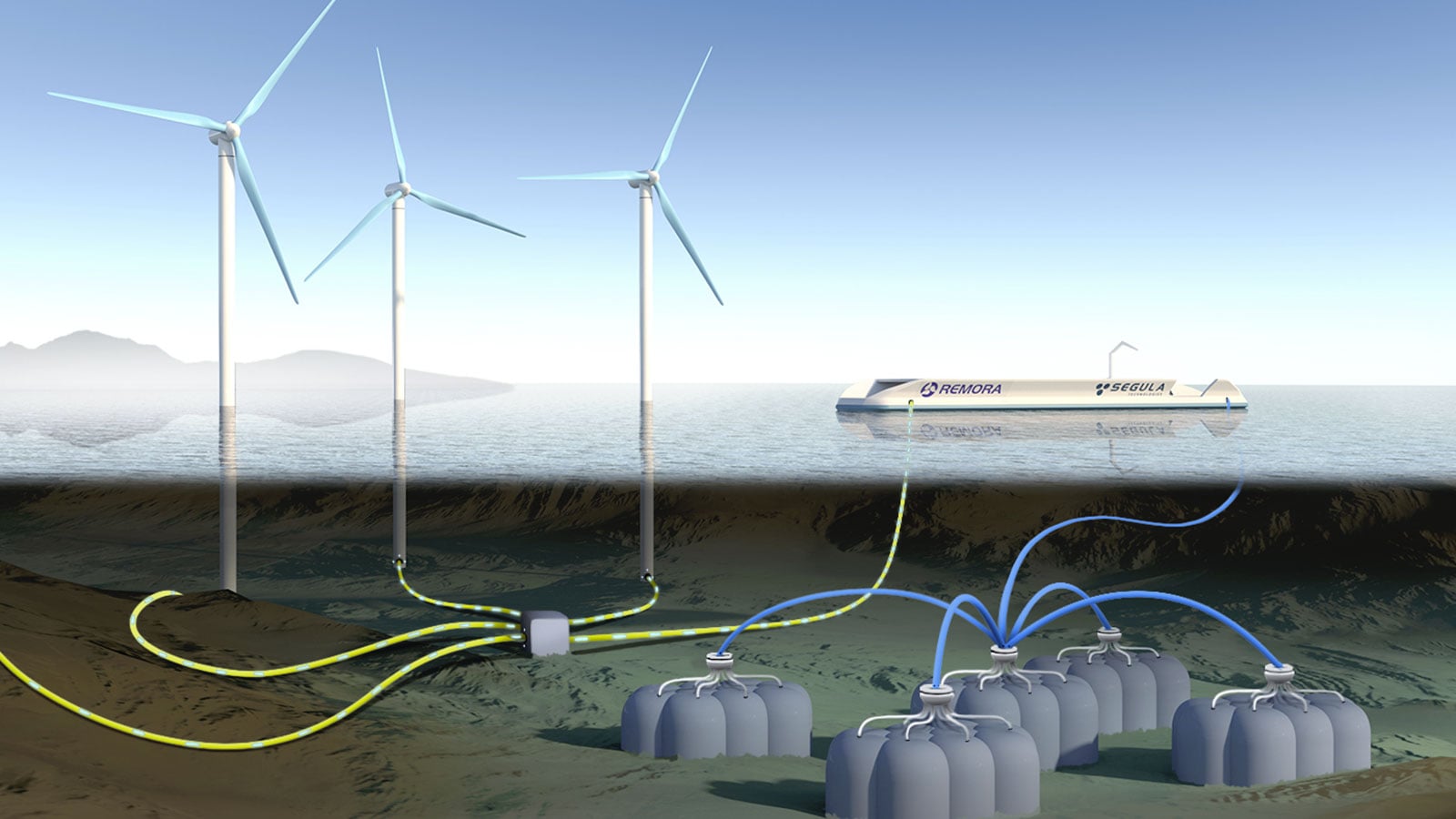

- Limited OPEX and CAPEX optimization.

- Simultaneous engineering is a token effort.

- Toolmakers are left to define process

Solutions

Manufacturing performance is key throughout development:

Proactivity in DFM suggestions with Product Engineering. DFM standards to be applied for re-usable processes.

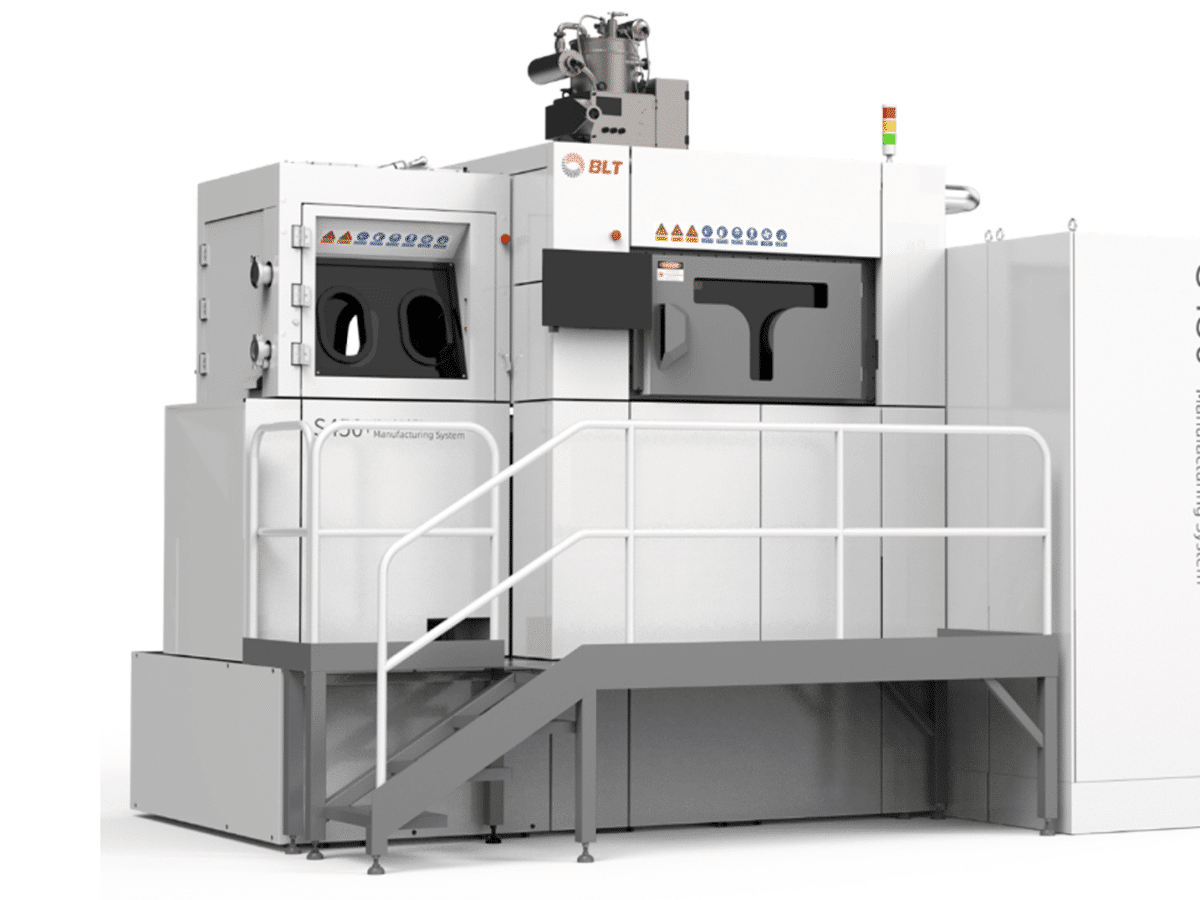

Neutral CAPEX reduction & best practices implementation.

Holistic approach for simulation and process planning.

Collaborating with the design, suppliers & toolmakers

Simultaneous Engineering is key for efficient product launch

Involvement of Civil, Facilities, MP&L; from strategy development to current manufacturing.

The faster a redesign requirement is identified, the less expensive and the more controlled it gets.

Cross-function working optimises CAPEX, anticipates issues, accurate make/buy strategy.