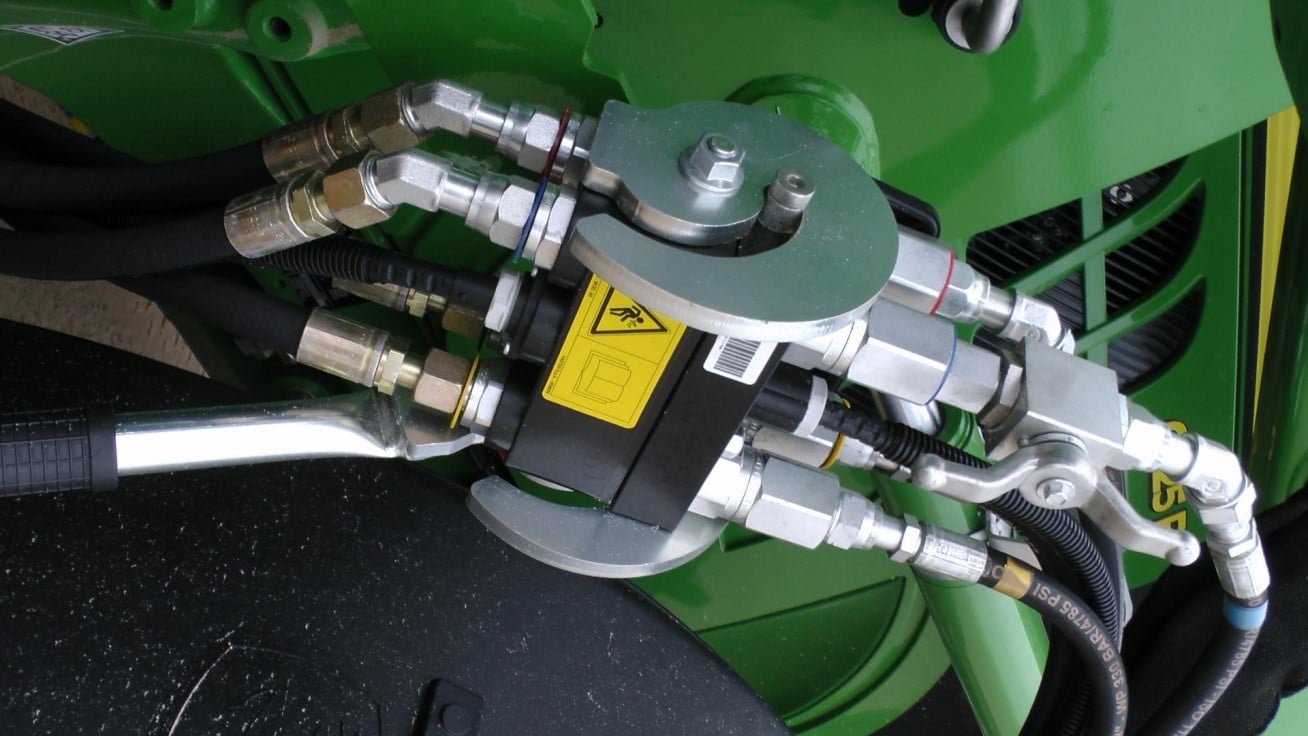

Honing is the precision machining process in which a very fine surface on a workpiece is produced using an abrasive tool. High quality honing of hydraulic cylinders is essential, as the effective operation of the pistons depends on the cylinder having a very fine surface finish, which can also prevent premature wear of moving components. Honing also creates a secure seal around a hydraulic cylinder, providing extended life and preventing costly leaks.

How Hydraulic Cylinders Work

In hydraulic systems, cylinders usually come in pairs, each of which houses a piston, one smaller than the other. The cylinders are partially filled with a suitable hydraulic fluid, such as oil, which can be transmitted between them via a connecting pipe that sits perpendicularly between the two. When the system is in operation, the hydraulic fluid in the cylinder with the smaller piston will be forced under pressure through the pipe into the other cylinder, driving the larger of the pistons with a magnified force. Using cylinders of different sizes, the system can exert enough force to lift, push, or pull heavy weights.

Why Honing Is Important In Hydraulics

Honing is an important part of surface preparation for hydraulic systems and offers numerous benefits that will improve its efficiency, lifespan, and precision:

1) Efficient, robust pistons: pistons in hydraulic systems are subjected to considerable strain, being in constant operation, so protecting them from friction, premature wear, and fluid resistance is vital if they are to work efficiently. Surface honing of the cylinder and carefully matched pistons can significantly increase their lifespan and improve tolerances, ensuring a more precise push when operating.

2) Reduced chance of component failure: hydraulic failures are expensive, inconvenient, and, in some industries, such as aerospace manufacturing, can be critical to the safety of consumers. Honing can ensure the surface of crucial components is free from inconsistencies that could cause the metal to wear unevenly. Honed pistons also wear more slowly, as honing facilitates smoother movements within the hydraulic cylinders.

3) Improved Transmission Of Fluids: efficient transmission of the hydraulic fluid between cylinders is essential for the system to operate effectively. A honed tube for the hydraulic cylinder will ensure that inconsistencies are eliminated, leaving a machined surface that is smooth to facilitate the fast and consistent transmission of fluid through the system.

4) Accurate metalwork inspections: hydraulic cylinder honing can also facilitate a more accurate, informed inspection of the hydraulic system, highlighting flaws and deficiencies such as scratches or dents that could render it prone to failure. With a full view of the problems, personnel can determine the most appropriate action, such as carrying out additional honing, refurbishing or replacing the affected section.