This is how QUICKGRIND’s technology helped NMIS go from 15 tools to just one!

By Rowan Easter-Robinson

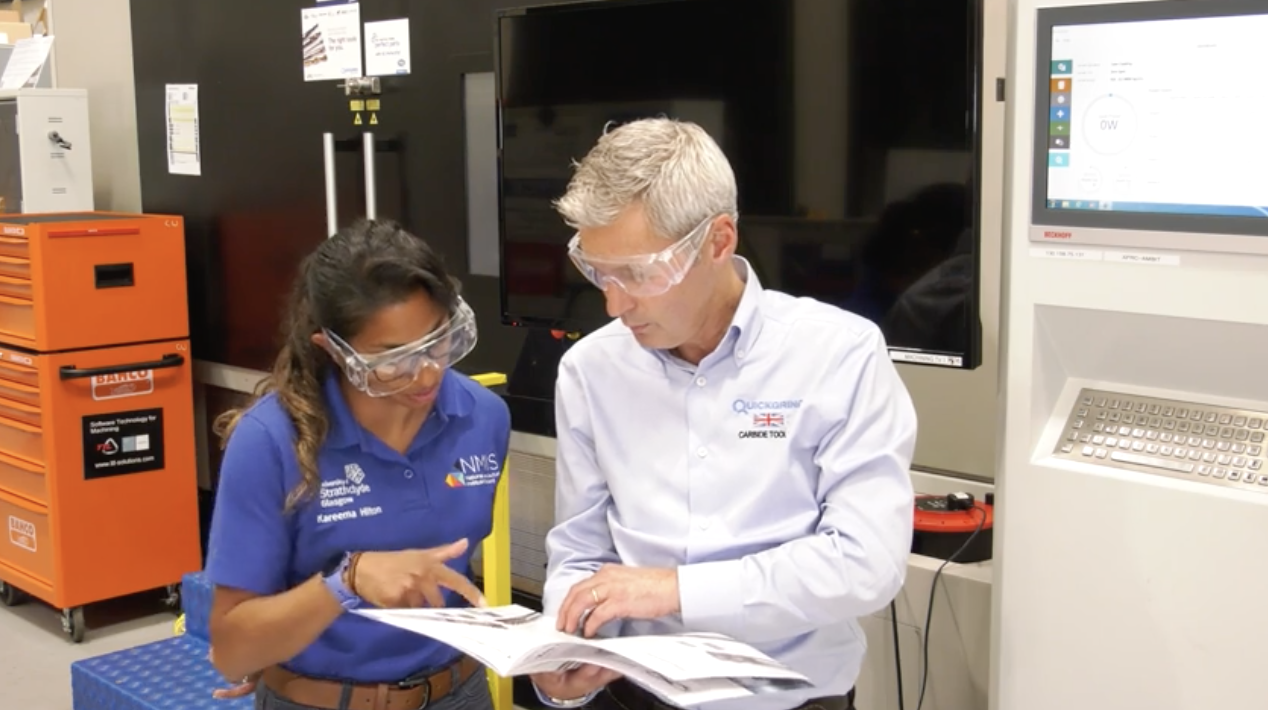

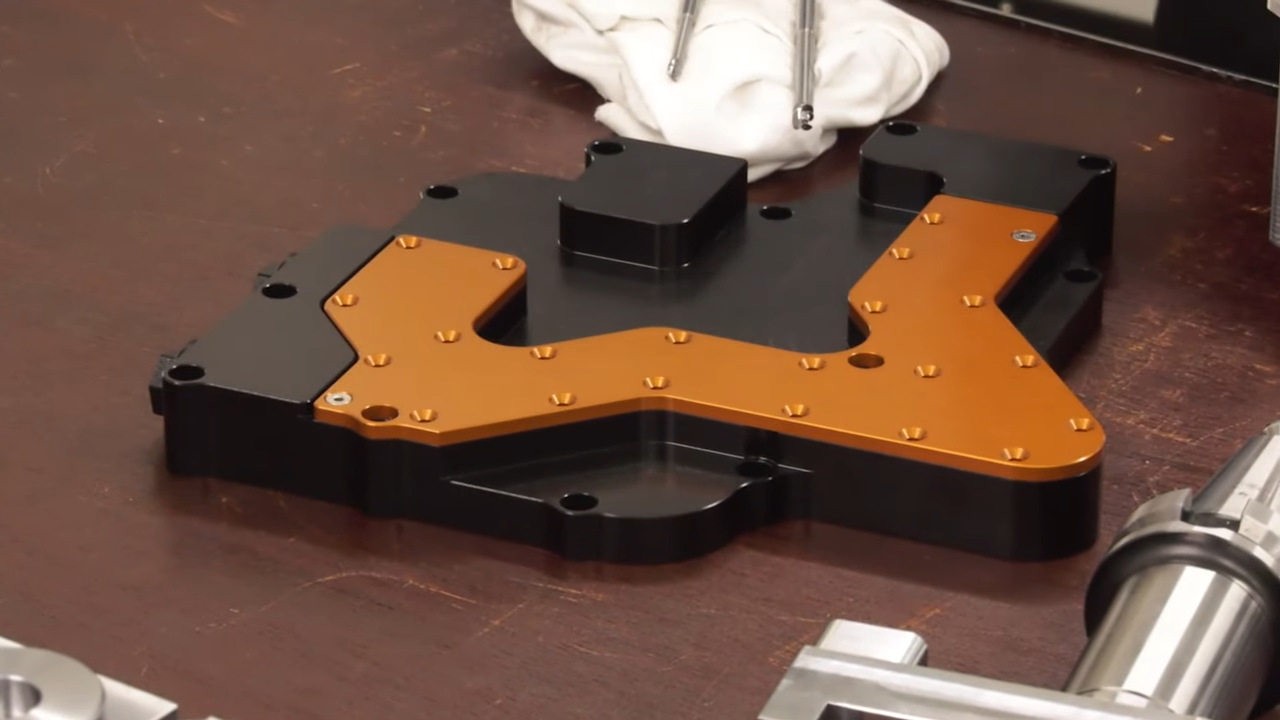

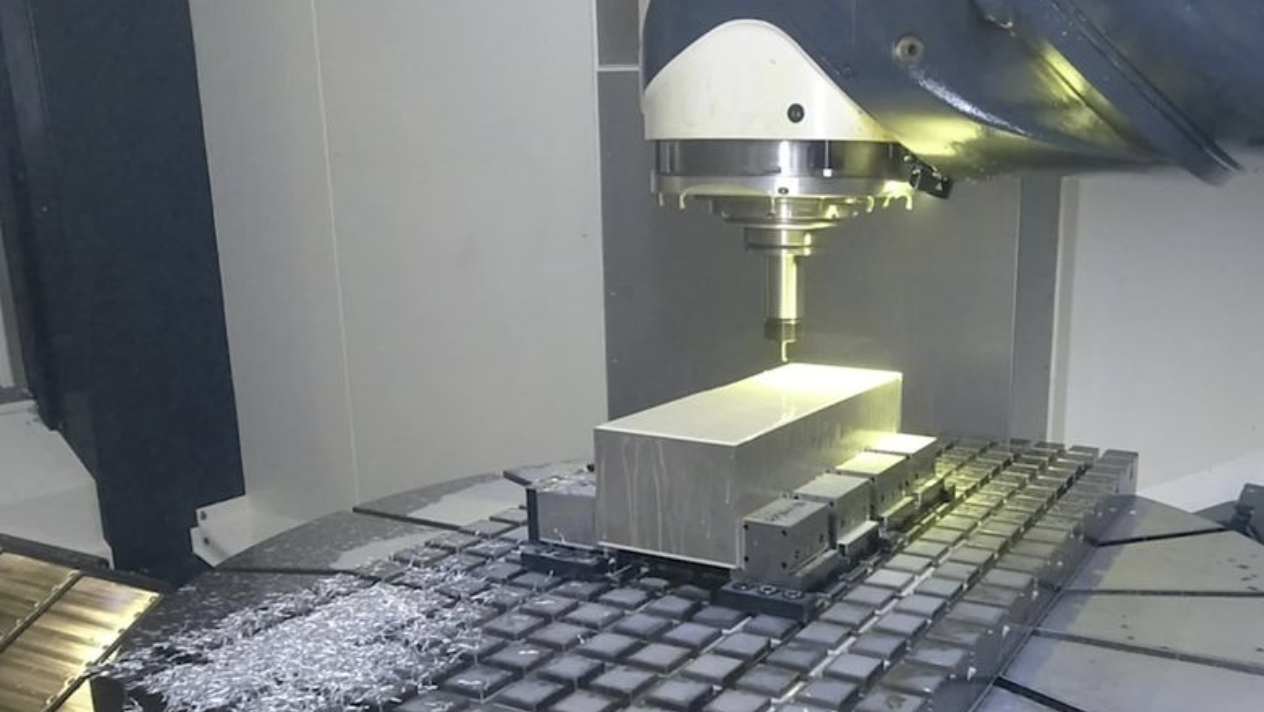

Rowan Easter-Robinson of MTDCNC is with Ryan Devine of NMIS to talk about additive manufacturing through laser metal deposition and how QUICKGRIND provided the right solution for their business. NMIS have been working to design a proof of concept for oil and gas companies. This process of additive manufacturing on Inconel 625 involves building layers onto a blank substrate and then machining the part to provide a quality surface finish. Before using QUICKGRIND, the process resulted in wearing out of the tools with up to 15 tools being used for a single part! With QUICKGRIND’s Spectre tooling, NMIS are now able to complete the machining with just a single tool. Find out how Spectre tooling has helped NMIS save big on time, regrinding, and tool life to end up with a beautifully finished part.

[ID3074118037]