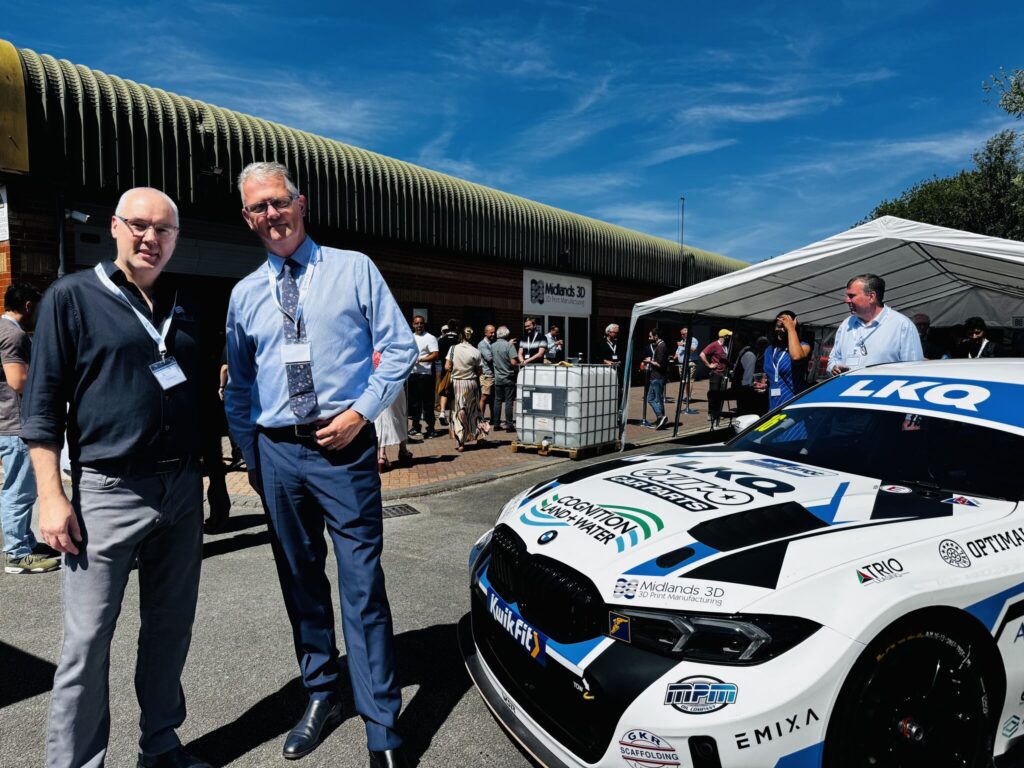

Midlands 3D Printing Ltd opened the doors to their brand-new facility yesterday, welcoming customers, partners, and industry friends to celebrate a major milestone in their journey.

With sunshine, refreshments, and factory tours, the atmosphere was buzzing throughout the day. Guests had the chance to see firsthand how Midlands 3D is evolving from a specialist in small-volume manufacturing into a serious player in additive production parts.

Leading the day’s discussions was Paul Moloney, who barely had a moment’s rest as visitors were eager to learn about the rapid advancements in 3D printing technology and the growing real-world applications for industries across the board.

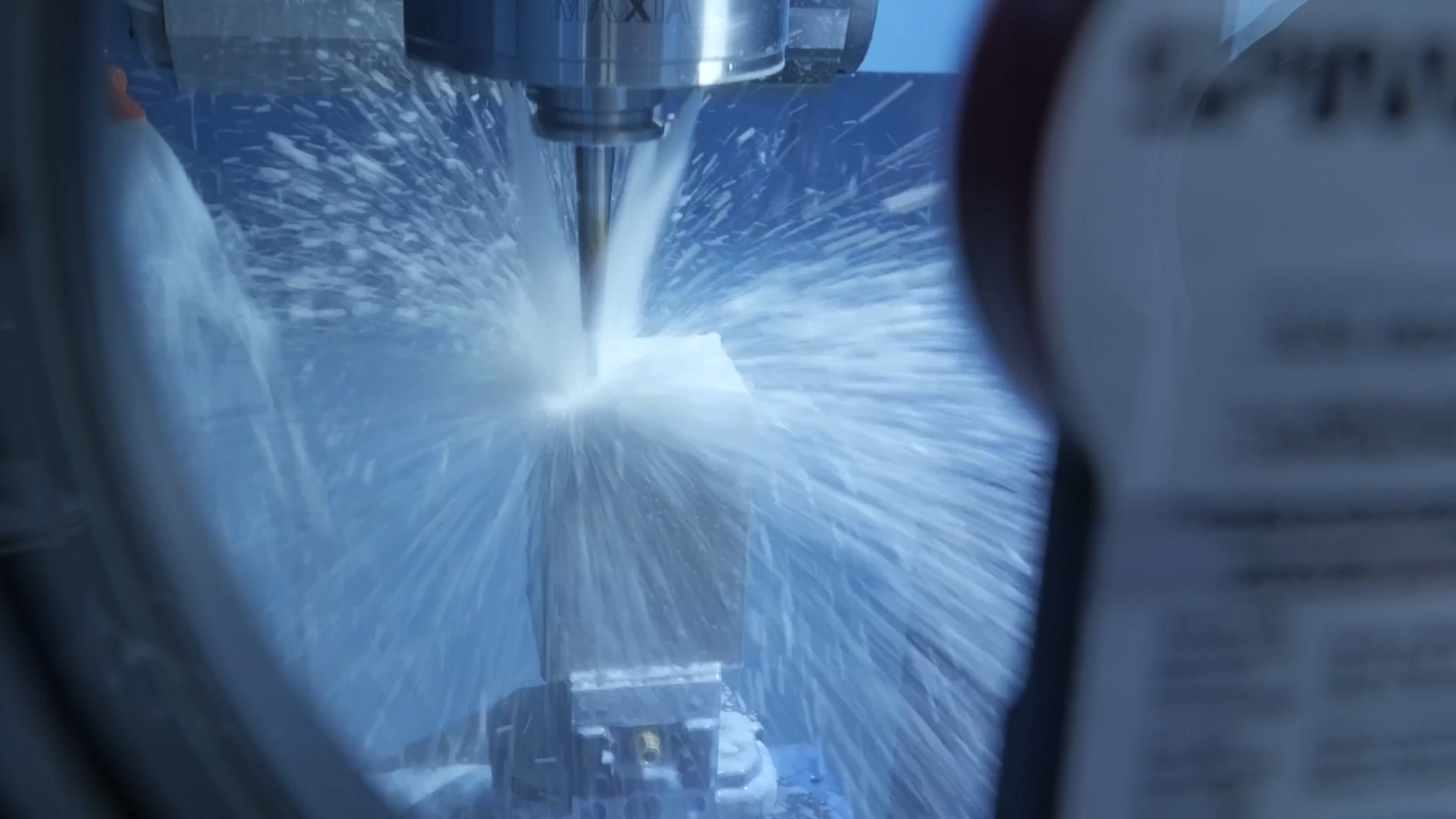

While many already understand the cost and speed benefits of 3D printing for prototypes and low-volume work, it’s clear Midlands 3D is now pushing into the next phase — scaling up additive production, providing robust, high-quality parts with repeatability and consistency.

Supporting this growth is Matsuura Machinery Ltd, whose role has extended far beyond just supplying machines. Matsuura has been pivotal in shaping the entire operational infrastructure, helping Midlands 3D unlock new levels of efficiency, reliability, and scalability in their production processes.

The open day was a fantastic opportunity to see what’s next for Midlands 3D and how modern additive manufacturing is quickly becoming a go-to solution for both prototypes and full-scale production.

Congratulations to the Midlands 3D team on their new facility and exciting next chapter — it’s clear they’re just getting started.