Drurys Engineering Supercharges 5-Axis Capability with Matsuura MX-330 PC10 Investment

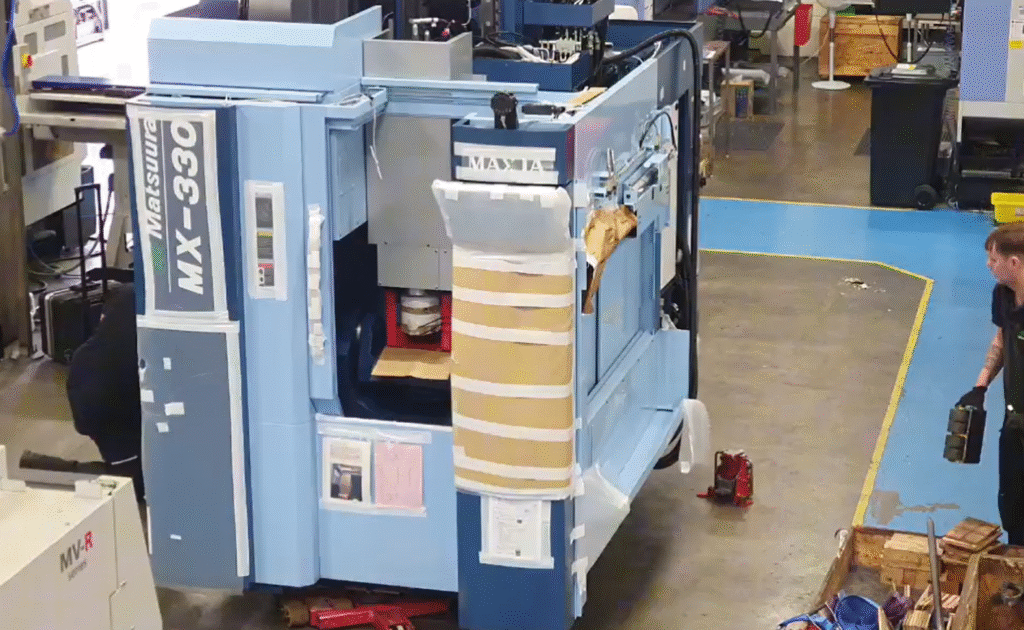

Big day at Drurys HQ – and a big statement of intent from a forward-thinking subcontractor.

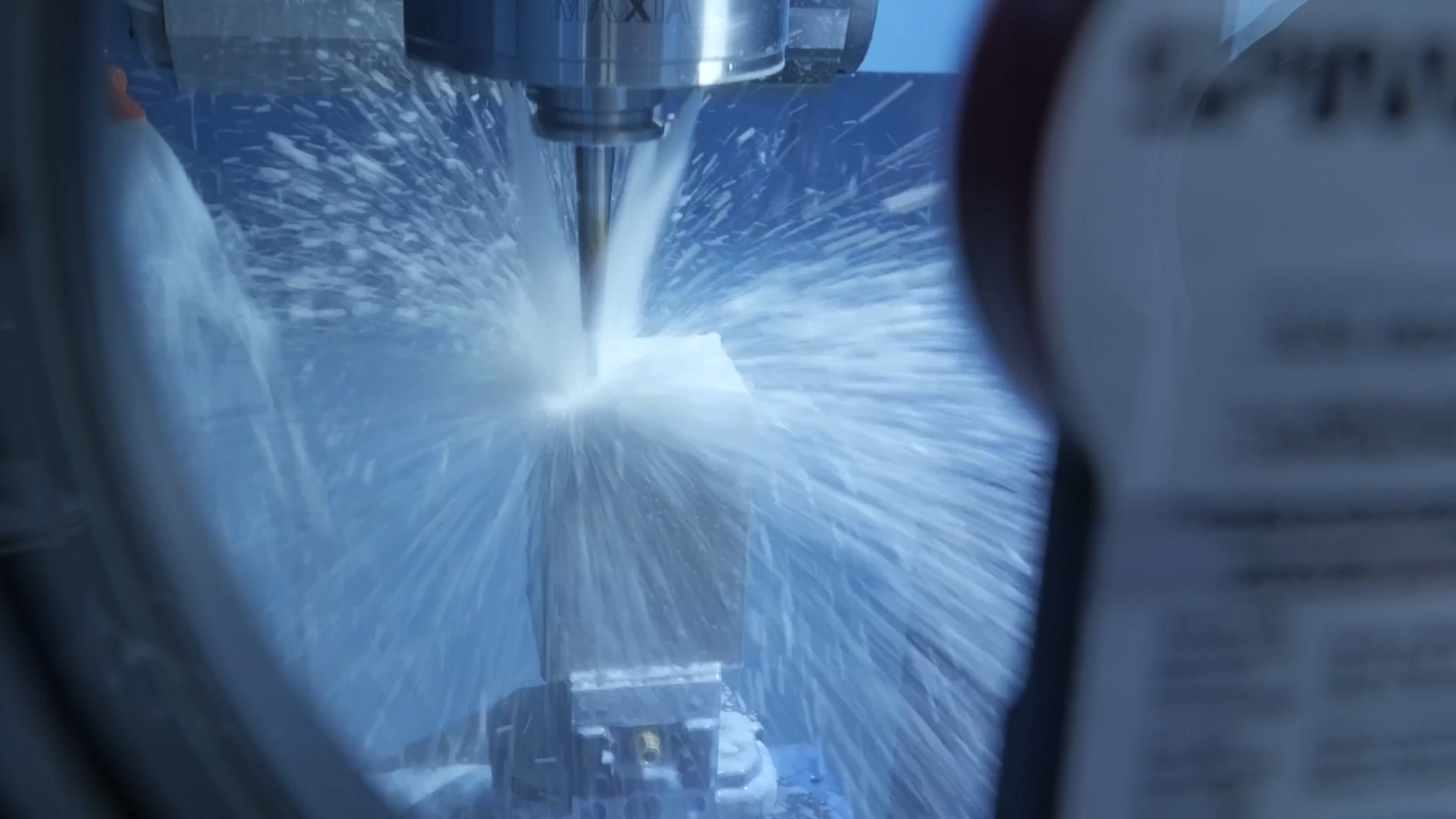

The team at Drurys Engineering has just taken delivery of a brand-new Matsuura MX-330 PC10 – a 5-axis vertical machining centre equipped with 10 pallets for high-mix, lights-out manufacturing. This latest investment adds serious capacity and automation to Drurys’ already impressive stable of CNC technology.

For over 20 years, Drurys Engineering has been a trusted name in precision subcontract machining. Based in the UK and serving industries from motorsport to medical, Drurys has carved out a reputation for delivering exceptional quality, flexibility, and customer service. With the addition of the Matsuura MX-330 PC10, the business is now geared up to handle more complex, multi-operation work with shorter lead times and improved productivity.

Matsuura’s MX-330: A Subcontractor Favourite

It’s no surprise that Drurys chose the MX-330 PC10. Across the UK, Matsuura’s MX range has earned a strong reputation among subcontractors who need a blend of reliability, precision, and automation. With its 10-pallet system, the MX-330 allows unmanned running across multiple jobs and setups — an ideal solution for subcontract manufacturers balancing one-offs, small batches, and repeat production.

For Drurys, this isn’t just about adding another machine — it’s about scaling smarter. By automating 5-axis production with the pallet system, they can now queue up different components, switch jobs mid-cycle, and maximise spindle uptime — even outside of staffed hours.

Ongoing Investment in Technology and Talent

Drurys’ latest addition is part of an ongoing programme of investment that’s seen the company continually raise its game. As customers demand faster lead times, tighter tolerances, and more efficient delivery, Drurys is answering the call — with high-end machine tools and the skilled team to match.

A Bright Future for Drurys and Its Customers

With the MX-330 PC10 now in place, customers can expect faster turnarounds, more production flexibility, and the same rock-solid quality that Drurys is known for. Whether it’s a batch of complex aerospace components or a high-value, one-off prototype, the company is now even better equipped to deliver.

More machines. More capacity. Same premium quality.

It’s a win for Drurys — and a win for their customers.