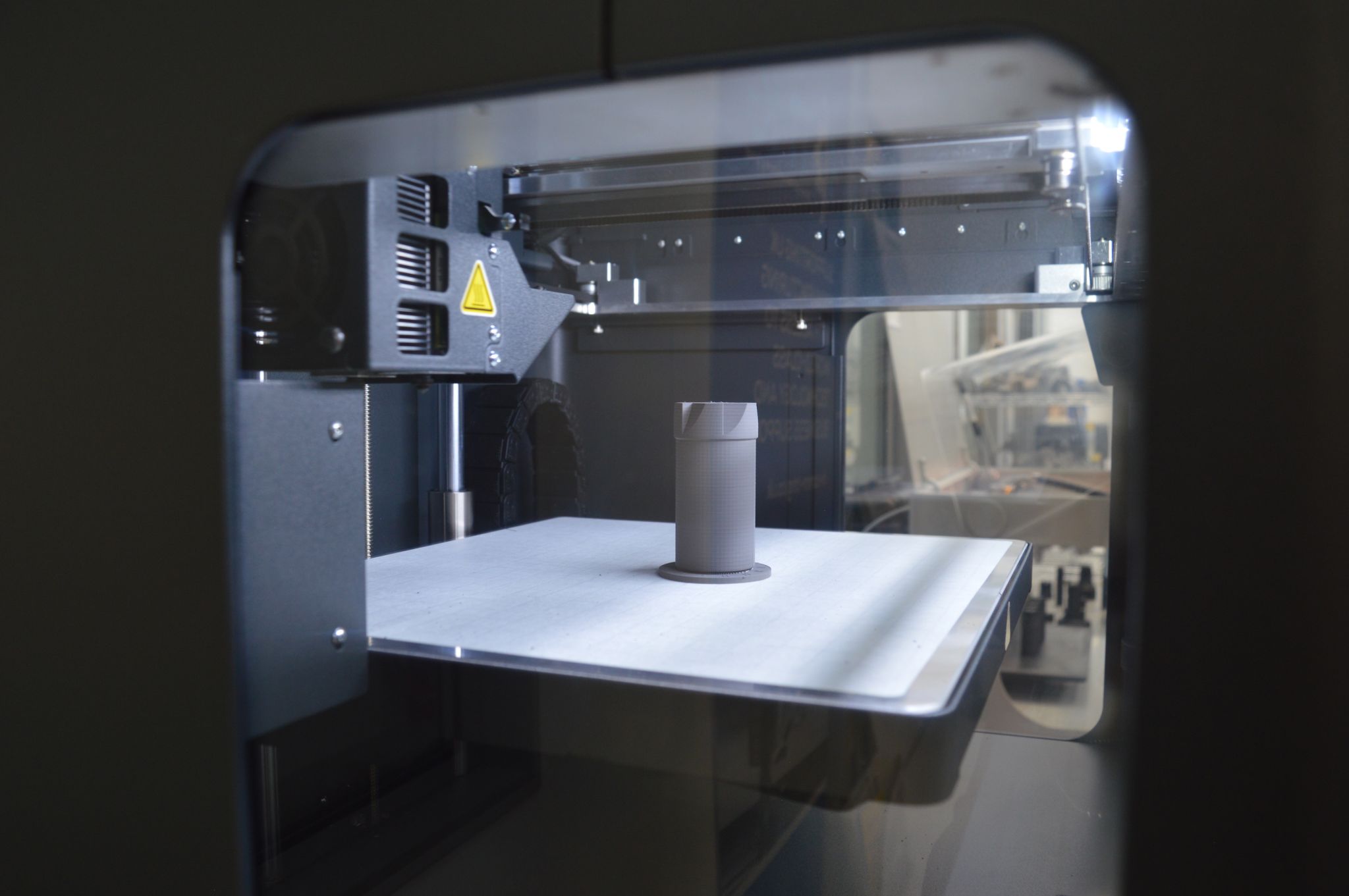

Guhring UK continues to show why they’re one of the most forward-thinking names in cutting tool manufacturing, by embracing metal 3D printing to accelerate the development of their tools.

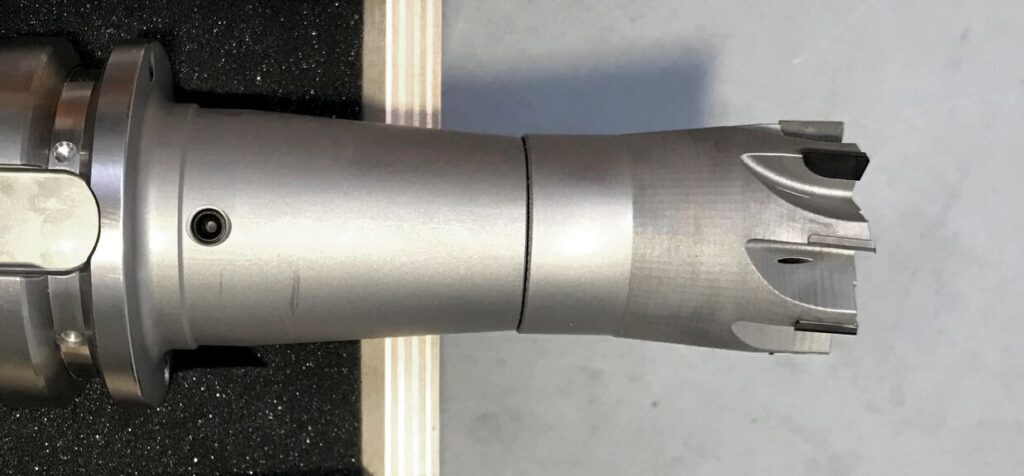

In a recent project, Guhring used H13 tool steel to produce fully functional metal prototypes of cutters and milling fixtures — all within just one day.

This rapid turnaround has allowed them to validate new designs quickly, make improvements early, and avoid the time and cost traditionally associated with producing prototype tooling through conventional CNC methods.

By using metal 3D printing to their advantage, Guhring is:

- Speeding up the design-to-test cycle

- Reducing machine setup time and scrap

- Lowering prototype costs without sacrificing metal fidelity

- Creating more room to experiment with innovative tool designs

This isn’t just about keeping pace with modern technology — it’s about leading the way in smart, agile manufacturing. Guhring’s approach is proof that even in industries built on precision and tradition, there’s huge value in adopting new processes that cut lead times and open the door to faster innovation.

It’s great to see a UK manufacturer combining engineering expertise with modern production strategies to keep delivering performance without compromise.