Billet Precision Accelerates Growth with DMG MORI Machine Investments

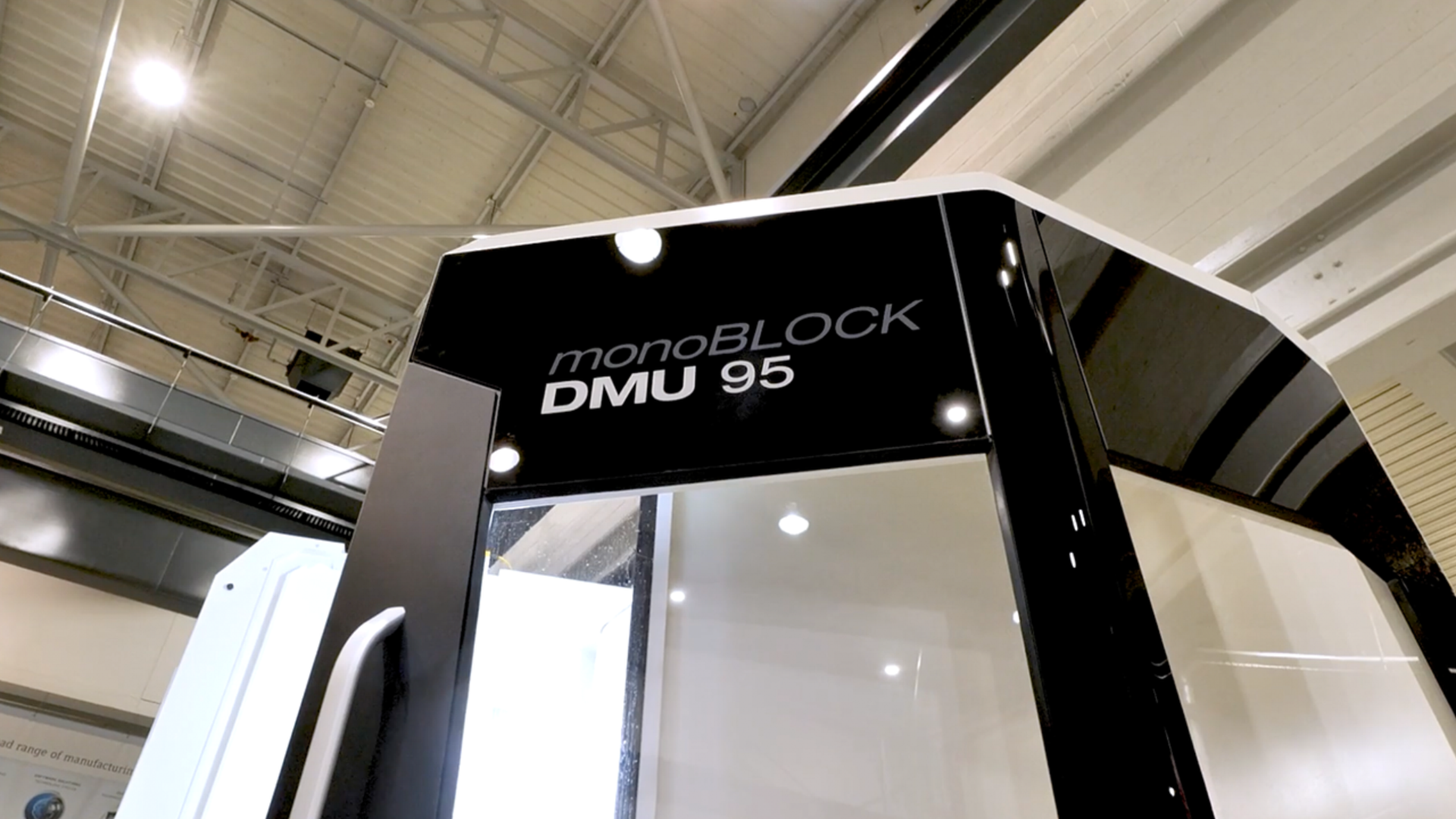

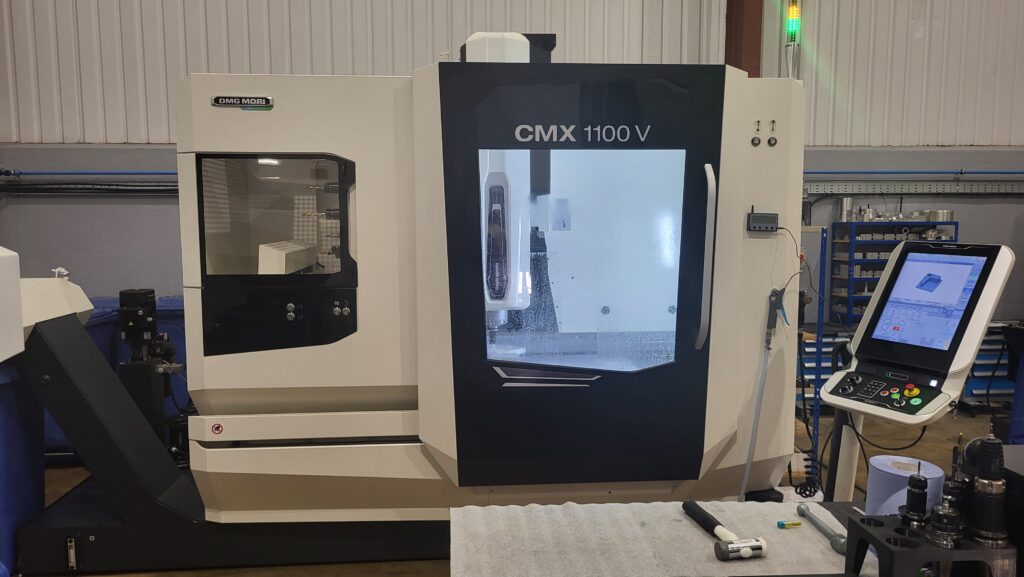

For many new subcontract manufacturers, choosing the right machine tools is one of the biggest decisions when starting out. For Billet Precision Ltd, founded just over a year ago, the choice was clear – invest in three brand-new DMG MORI machines to set the foundation for long-term success.

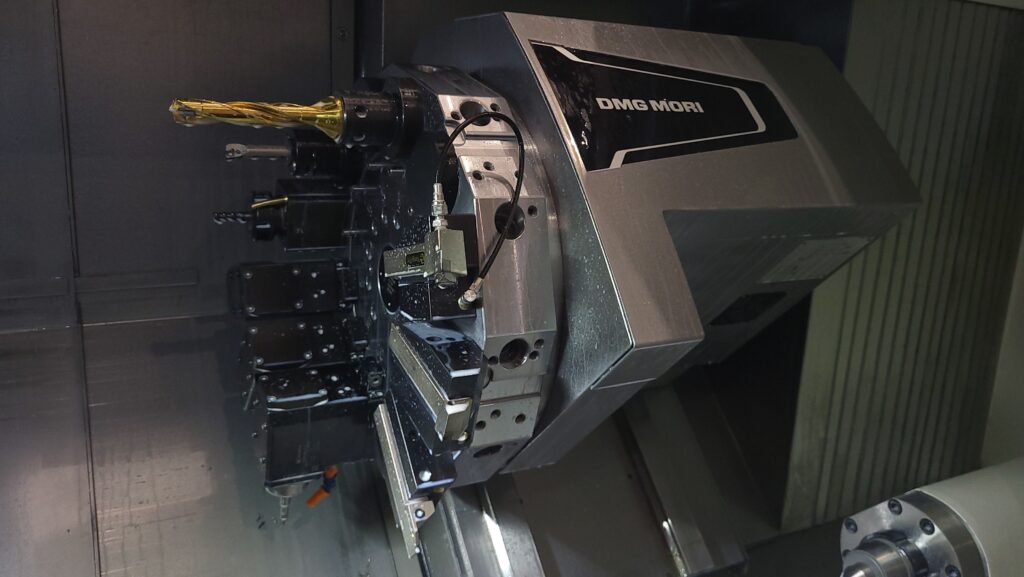

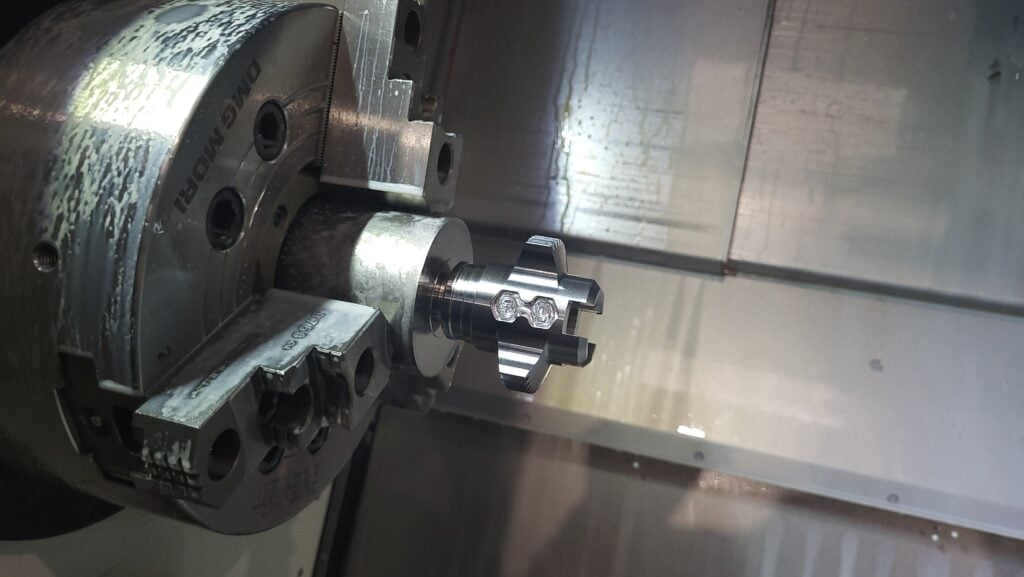

By combining 3- and 4-axis milling with multi-axis turning, the company has built an adaptable machining capability that ensures no part is turned down. This versatility has already positioned Billet Precision as a reliable partner for customers with diverse and demanding requirements.

As an owner-operated business, efficiency and reliability are critical. Co-founder Ryan explained how DMG MORI’s technology makes the difference:

“It’s the repeatability and consistency of the machines that help us produce all of our parts right first time. Being a small, hands-on team, we can’t afford rework – so this level of accuracy is invaluable.”

The company’s investment strategy reflects its ambition to grow steadily and build a reputation for quality from day one. With Ryan, Will, and James at the helm, Billet Precision is already demonstrating the advantages of starting strong with world-class equipment.

The MTDCNC team recently visited Billet Precision to see the machines in action and speak with the team about their first year in business.