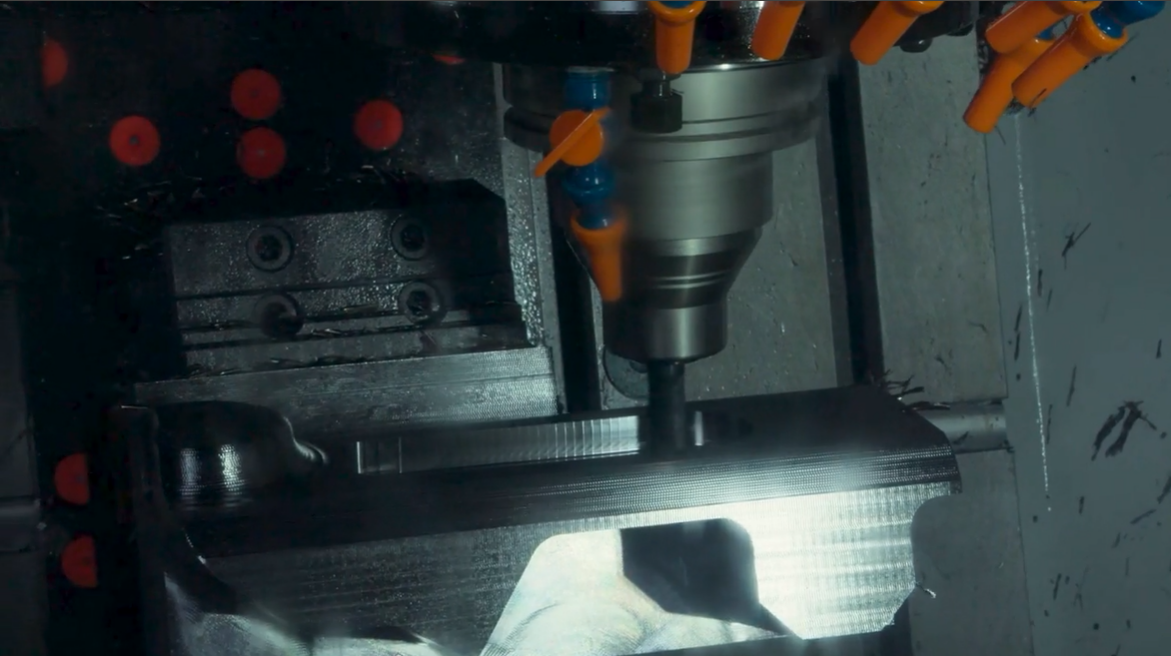

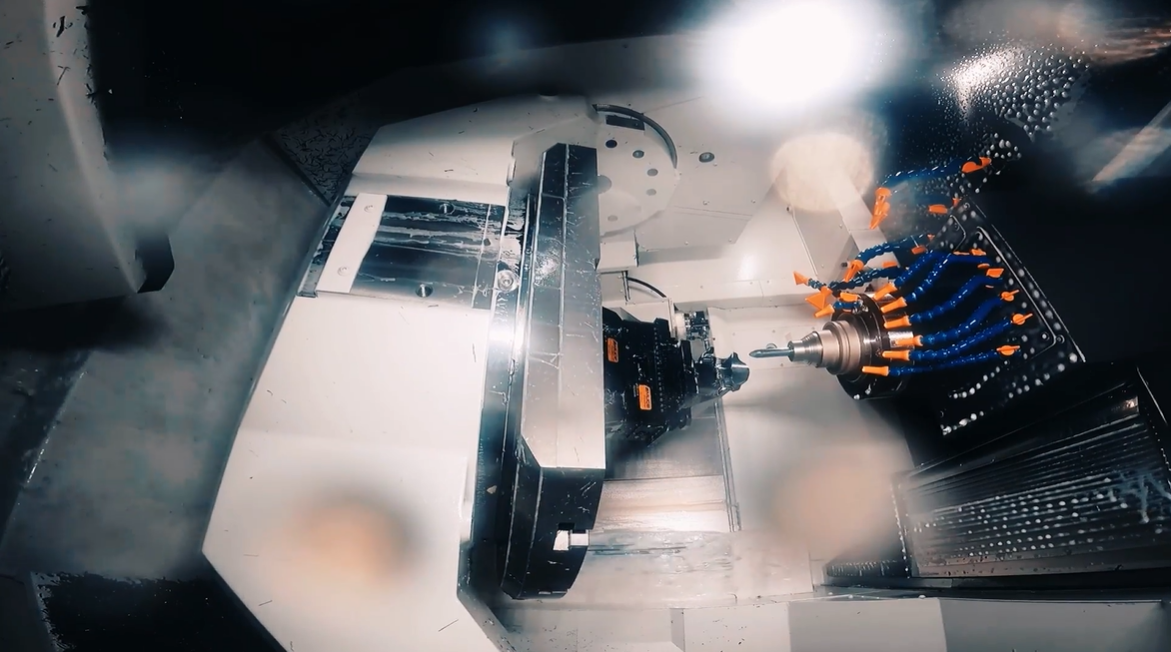

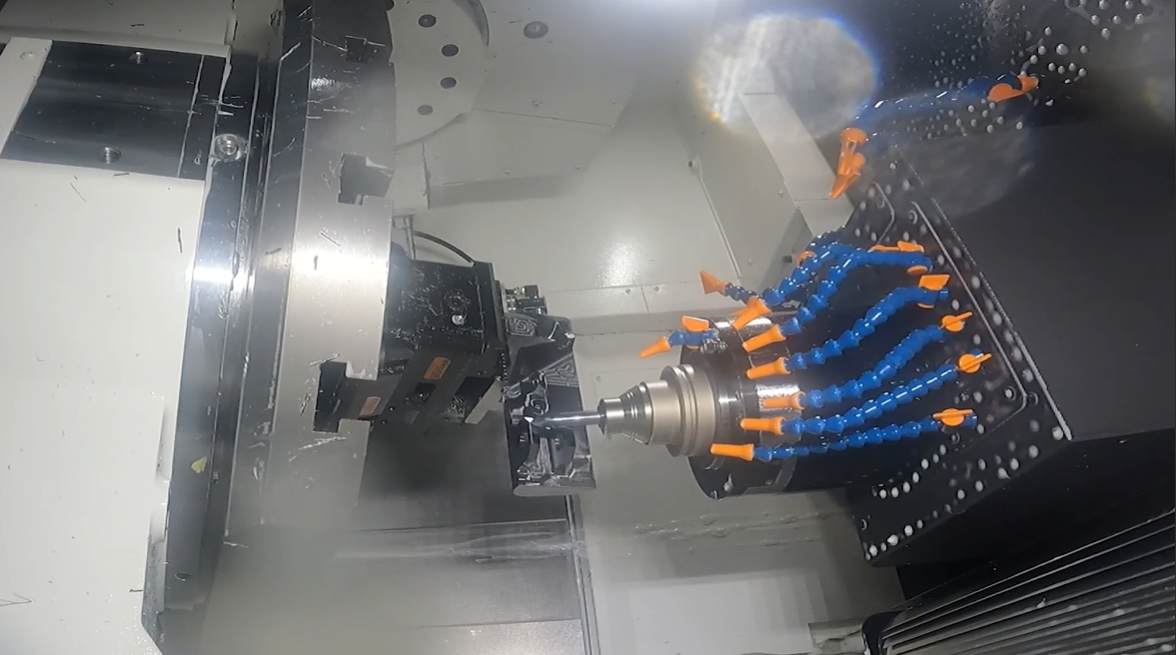

What’s really happening inside Emuge-Franken’s U.S. HQ?

They’re running 24/7 with unmanned shifts! MTDCNC’s Arthur Field takes us inside Emuge-Franken’s U.S. facility in Massachusetts to see how they continue investing in North American manufacturing. From advanced technology and training centres to in-house edge prep, PVD coating, and lights-out robot…

MTDCNCLast viewed

MTDCNCLast viewed

Total Posts

24

Total Social Posts

28

Supplier

EMUGE FRANKEN USA

1800 Century Drive, West Boylston, MA 01583, America

About

EMUGE-FRANKEN USA (U.S. and Canadian Headquarters in West Boylston, MA U.S.A.) is a wholly owned subsidiary of German parent company EMUGE-Werk Richard Glimpel KG, a leading manufacturer of precision taps, thread mills, drills, end mills, tool holders, clamping devices and other rotary tools for over 100 years. Over 10,000 types of high performance cutting tools and accessories are stocked in the U.S., with over 40,000 items sold through distributors worldwide.

16 January 2026

From Standard to Specialised Milling Tools – Taking You One Step Further

EMUGE-FRANKEN offers a comprehensive milling program that combines versatility, precision, and uncompromising quality. Our range includes end mills and bore cutters in HSS and solid carbide, as well as high-precision special tools, including form milling cutters and profile milling cutters. For demanding applications, we also provide PCD and CBN end mills, and tools with indexable inserts. A complete system of tool holders and chucks ensures you have everything you need for efficient milling. We are specialists in milling technology. Our forward-looking development of milling strategies opens up new possibilities for your machining. Using advanced simulations, we design tool geometries tailored

View Product

16 January 2026

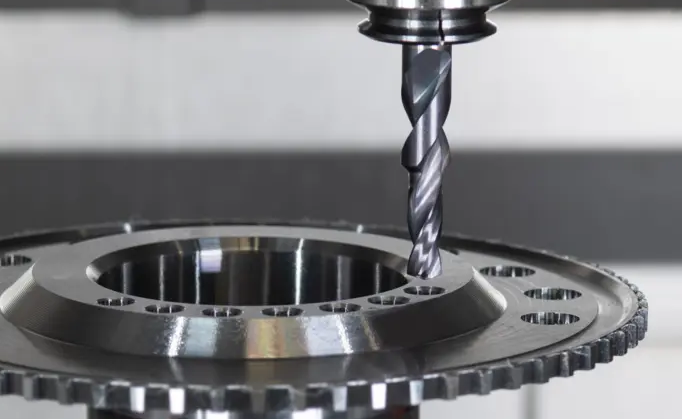

BasicDrill CM C – Fully Customisable, Ready for Any Challenge

The BasicDrill CM C takes versatility and precision to the next level. This innovative universal chamfer step drill is designed for demanding applications, featuring integrated internal cooling for optimal performance and reliability. What sets it apart is its customisability: within defined parameters, you can configure your twist drill to match your exact requirements, with a uniform length and a fixed price—ensuring a perfect fit for your process. With EMUGE’s Quickline-Service, speed meets flexibility. Our fully automated production process dramatically reduces lead times, meaning your first custom chip can be produced in just 24 hours. Currently available for the BasicDrill CM

View Product

16 January 2026

BasicDrill Performs Best with Feed – Don’t Hold It Back

The BasicDrill is designed to run with higher feed rates. While conservative values may feel safe, they don’t unlock the full potential our engineers built into the tool. With the right feed, BasicDrill delivers its strongest performance—improving productivity, stability, and overall efficiency. Its strengths are proven in demanding applications such as worm shafts, joint rings, crankshafts, turbine housings, and wheel hubs—and many more beyond that. If your application isn’t listed, that doesn’t mean it’s not suitable. We’re confident we can develop the right drilling concept for your specific requirements. To make tool selection even easier, EMUGE is introducing three clear

View Product

What MTDCNC can do for you

Your partner for marketing, media, and events in manufacturing.

Join Thousands of Professionals Staying Ahead with MTD

Sign up to receive the latest videos, insights, and exclusive content from the world of manufacturing