DC4

Wednesday 11 February 2026

Supplier Information

Detailed Specification

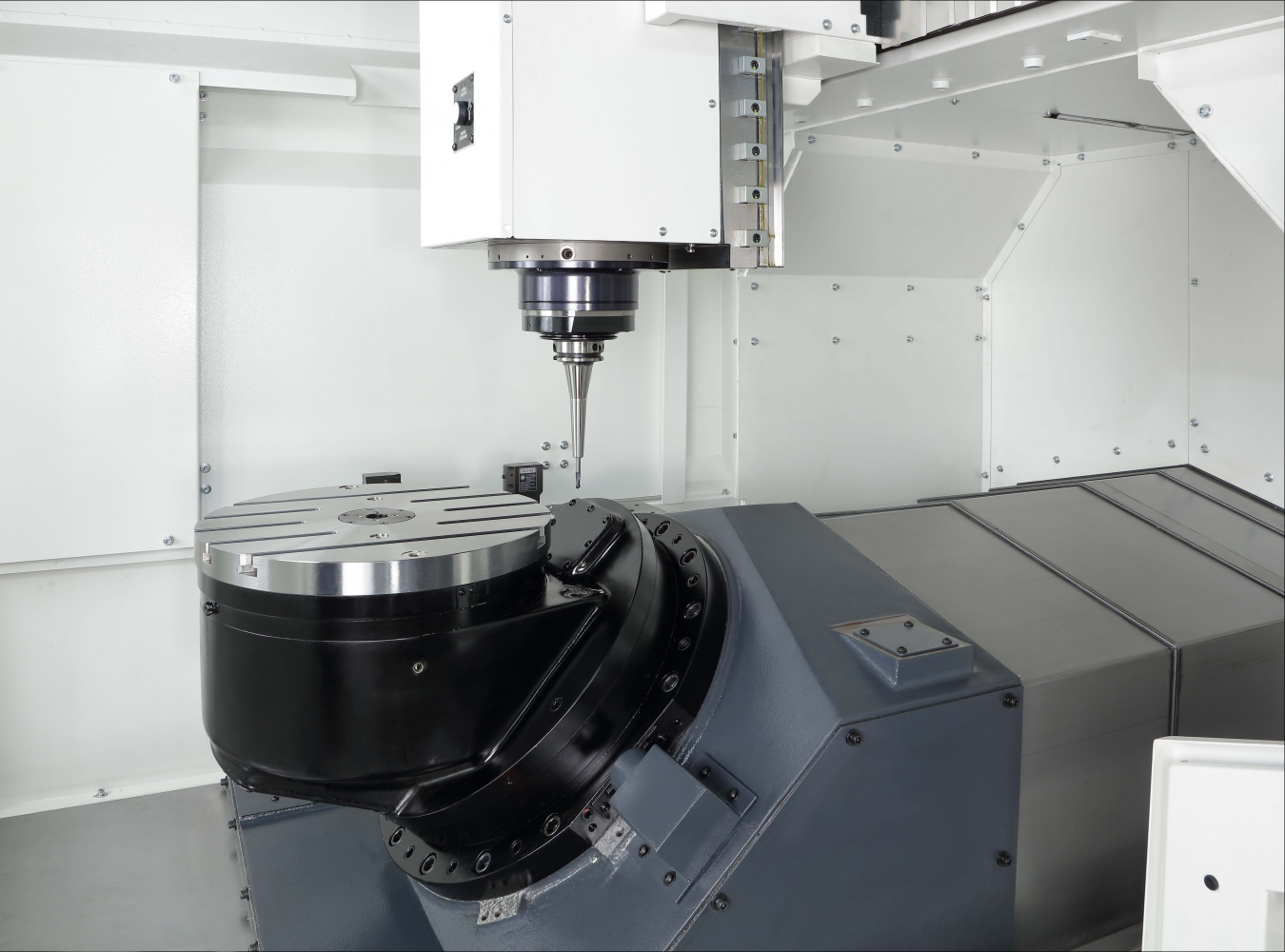

DC4 by axile

The DC4 is a new 5 axis masterpiece from AXILE with a 400mm size table and a machine structure which results in the combination of speed, rigidity, and accuracy. The Double Column design is comparable to a Bridge type construction with the table assembly moving along the X axis.

DC4 design places the spindle nearer to the centre of mass of the machine, increasing rigidity and offering superior stability. It reduces vibrations and maintains a high level of precision even during high-speed machining or when dealing with hard materials. This platform is perfect for application in aerospace, medical as well as die and mould industry. The machine can be equipped with different magazine capacity, starting at 80 tools up to 320 tools depending on your workload batches, the automation and the autonomy required.

The industry 4.0 technology, ART, the intelligent monitoring system is also available for AXILE DC4. AXILE offers a fully spec machine with everything you need to produce high-end parts with superior accuracy, so, equipment like linear scales, laser tool setter, workpiece probes, kinematic compensation software and even hydraulic and pneumatic ports for zero-point clamping systems, are all standard features in the DC4.

A snapshot of the AXILE – DC4:

- 400 mm size table and a machine structure which results in the combination of speed, rigidity, and accuracy in simultaneous 5 axes operations.

- Double-column bridge construction allows for greater rigidity, as well as greater control over thermal deformation.

- The unique rotary table design ensures that the centre of gravity of the table and workpiece are always captured within the centre of rotation of the A and C axis.

- High speed agile machining – Torque motor technology based rotary table with unbeatable acceleration and A axis speed at 100 RPM speed and C axis at 200 RPM.

Technology information

|

Model |

Description |

Unit |

DC4 |

|

STANDARD LINEAR AXES |

X |

mm |

715 |

|

Y |

mm |

670 |

|

|

Z |

mm |

400 |

|

|

STANDARD ROTARY AXIS |

Table diameter Ø |

mm |

400 |

|

Table load |

Kg |

300 |

|

|

A axis driven system |

Swivelling |

Torque motor |

|

|

C axis driven system |

Rotary |

Torque motor |

|

|

STANDARD AXIS DRIVE |

Ballscrew pitch |

– |

12 |

|

Maximum feed rate |

m/min |

36 |

|

|

Guideways |

m/min |

45 |

|

|

Lubrication type |

– |

Grease |

|

|

standard spindle |

Driven system |

– |

Built-in |

|

Maximum speed |

rpm |

20,000 |

|

|

Power S1/S6 (40%) |

kW |

23/36 |

|

|

Torque S1/S6 (40%) |

Nm |

77/120 |

|

|

Interface |

– |

HSK-A63 |

|

|

Bearing lubricant |

– |

Oil air |

|

|

Water chiller |

degree |

±0.2 standard |

|

|

STANDARD ATC |

Magazine capacity STD |

– |

80T |

|

Smart tool load station |

– |

Standard |

|

|

STANDARD VALUE-ADDED FUNCTIONS |

3 x hydraulic + 1 x pneumatic port interface on A/C table. |

||

|

Roof with door opening for overhead crane loading |

|||

|

Air through spindle (wet/dry rotary union) with solenoid to adjust air pressure |

|||

|

Linear scales for X/Y/Z axis |

|||

|

EMC + Safety module for CE regulations |

|||

|

LED signal lamp with 3 colours |

|||

|

Electrical parts preparation for BLUM laser tool setter |

|||

|

SMT function – TPC – Tool-tip Positioning Control |

|||

|

SMT function – SVS – Spindle Vibration Supervision |

|||

|

SMT function – AAC – Axial Accuracy Control |

|||

|

DCM function (Dynamic Collision Monitoring) |

|||

|

Levelling pad (height adjustable) |

|||