BVK4-50-3A

Wednesday 11 February 2026

Supplier Information

Detailed Specification

BVK4-50-3A by balance-systems

Automatic balancing machine

Features

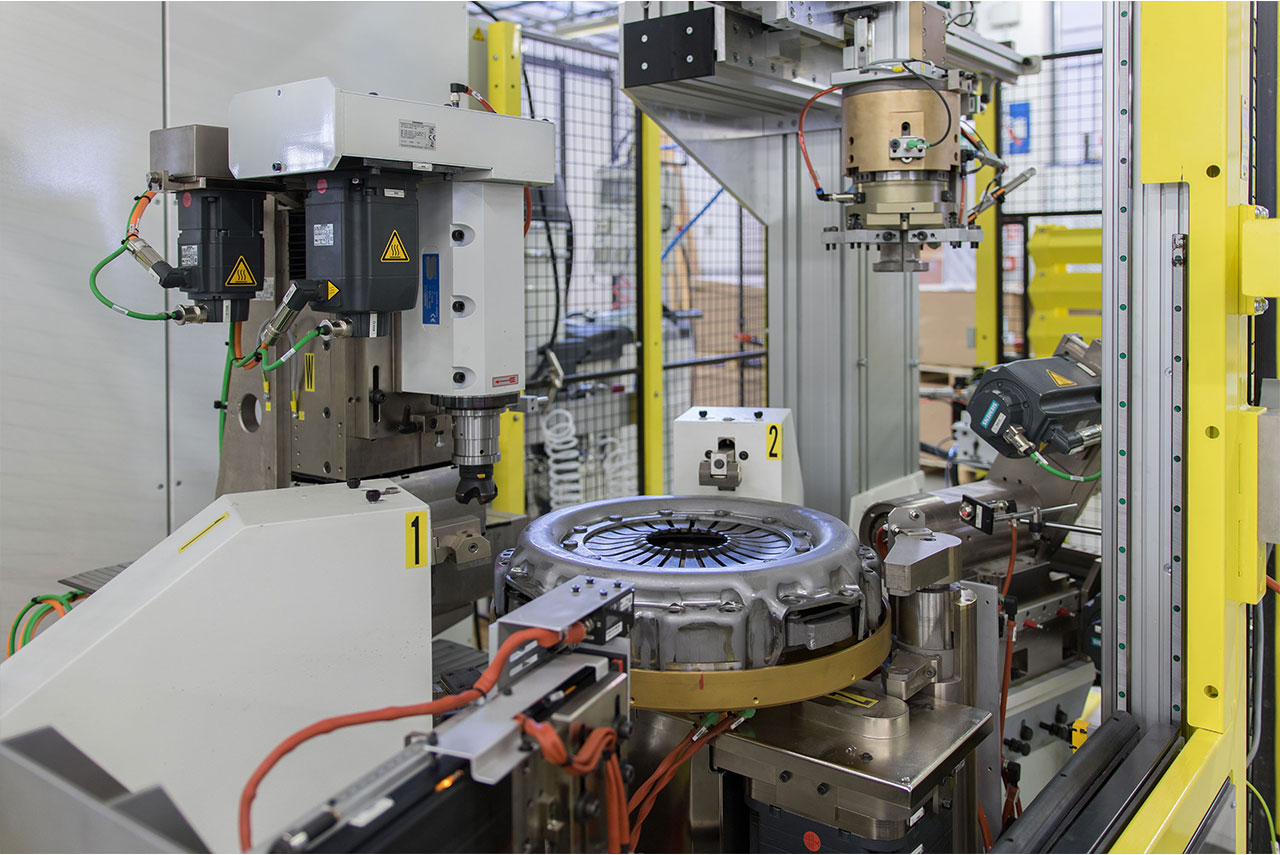

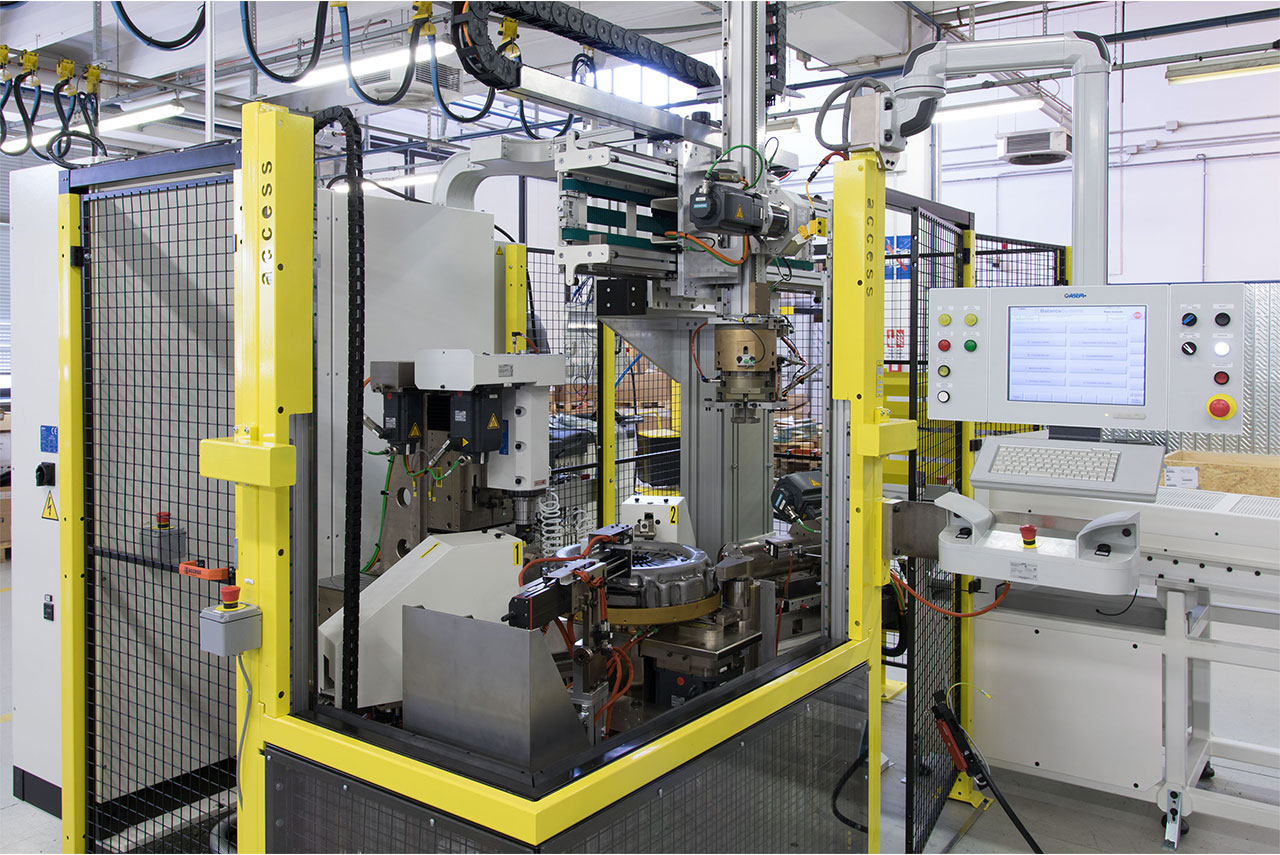

- Vertical automatic balancing machine, specifically developed for the balancing of assembled clutches on one plane (static). The unbalance is automatically corrected by axial milling and/or radial drilling.

- The milling unit is controlled by three axis and the correction is carried out by axis interpolation.

- It is composed of; measuring unit, axial milling with three controlled axis and an axial drilling unit (option).

- Parts loading is performed by an operator, while parts unloading is automatically performed by a controlled pick and place with an expandable gripper.

- High level of flexibility and quick production changeover.

Advantages

- High measuring precision

- High balancing precision

- Quick return on investment

- User friendly

Technology information

| Max rotor external diameter: | 500 mm (19.68 in) |

| Max rotor internal diameter: | 260 mm (10.24 in) |

| Max rotor height: | 80 mm (3.15 in) |

| Max rotor weight: | 60 kg (132.28 lb) |

| Cycle time: | < 100 s |

| Balancing method: | Axial milling and/or radial drilling |

| Balancing speed: | 500-700 rpm |

| Controlled by: | Industrial PC |

| Power: | 7 kVa |

| Power supply: | 400-480V+PE three-phase 50/60 Hz |

| Machine weight: | 3200 kg (7054.79 lb) |

| Machine dimensions (LxWxH): | 3500 x 3500 x 3320 mm (137.79 x 137.79 x 130.71 in) |