ModuleWorks has launched 2025.12 release of its software components for digital manufacturing and digital factory. This latest release offers a range of new, automated features designed to enhance machining efficiency, process safety and part quality.

Complex moulds and dies often feature deep pockets and sharp internal corners that are difficult to machine due to limited access and tooling constraints. Traditional 3-axis milling relies on long, slender tools, leading to higher costs, greater risk, and residual material that requires manual finishing.

ModuleWorks 2025.12 introduces a new Corner Finishing toolpath, designed to overcome these challenges by detecting uncut stock, generating stable tool centre lines, and merging optimised paths to minimise repositioning. It automatically adjusts toolpath strategies for both steep and shallow areas, ensuring accurate material removal, high surface quality and reduced manual polishing.

FeedControl dynamically adjusts toolpaths according to cutting forces and individual machine capabilities, helping engineers maintain stable cutting conditions, extend tool life and speed up machining cycles.

ModuleWorks 2025.12 offers a new option for defining custom process constraints directly within the FeedControl interface. By specifying parameters such as side load, chip load and power-torque limits, users can now fine-tune toolpaths to optimise machining efficiency and safety.

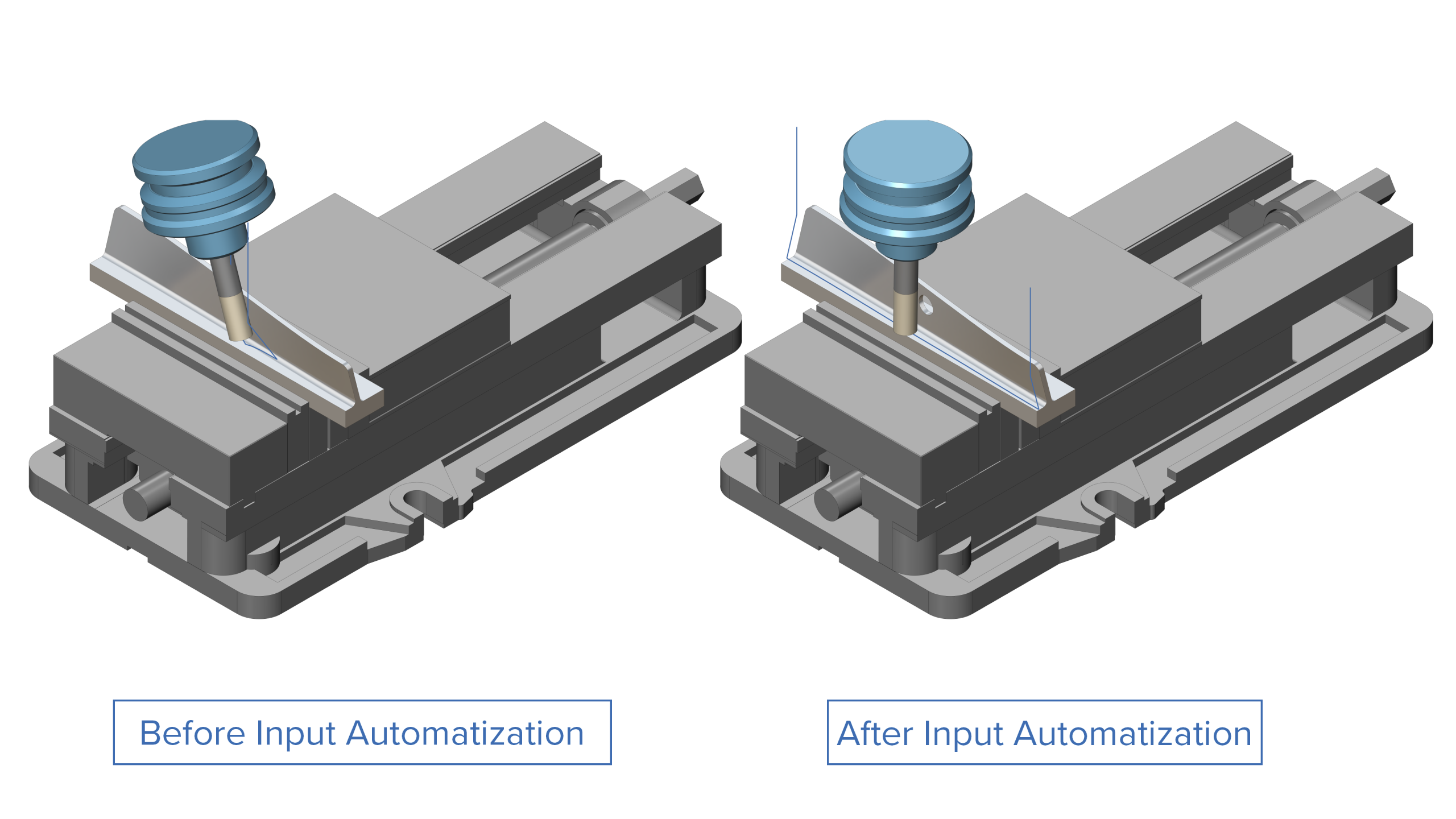

ModuleWorks 2025.12 offers a major improvement for SWARF machining. The latest update introduces enhanced logic for reliably detecting guide curves on surfaces, even those with rounded boundaries. This overcomes previous limitations, enabling consistent curve selection regardless of edge geometry. It also simplifies and speeds up the programming workflow, making it easier for users to handle diverse part topologies and achieve consistent results in complex machining scenarios.