In November’s issue of MTD, we explored how Hexagon Manufacturing Intelligence unveiled new measurement technologies at Oracle Red Bull Racing. However, the full-day event revealed the same technologies, proven in aerospace applications, are revolutionising automotive manufacturing. By Rhys Williams.

The convergence became clear as the day progressed from aerospace-focused sessions to automotive applications. Riana Rarimamonjy’s keynote on productivity challenges and Dr Ingo Lindner’s masterclass on digital manufacturing established principles that resonate across both sectors. The roar of Formula 1 engines might seem worlds apart, but Hexagon’s partnership with Oracle Red Bull Racing provided an unprecedented glimpse into how sub-micron precision, real-time measurement, and agile manufacturing translate seamlessly between aerospace and automotive.

Revolutionary Product Launches

The unveiling of four major product launches—MAESTRO CMM, ATS800 laser tracker, PRESTO XL inspection system, and Digital Factory as-a-Service—demonstrated how solutions initially developed for aerospace precision could address automotive’s high-volume production challenges.

The MAESTRO coordinate measuring machine, called ‘engineered from the ground up to meet rising productivity demands,’ offers automotive manufacturers fast, precise measurements. The ATS800 laser tracker’s automotive applications proved equally compelling. Its ability to perform accurate feature measurement from up to 40m without scaffolding or physical targets makes it ideal for measuring large automotive components such as body panels, chassis assemblies, and increasingly large electric vehicle battery packs.

PRESTO XL addresses the automotive industry’s fundamental challenge: achieving quality at the throughput necessary for mass production.

Digital Factory as-a-Service addresses automotive manufacturing’s facility modernisation needs as the industry transitions to electric vehicle production. Legacy automotive plants, like their aerospace counterparts, often lack reliable layout data following decades of modifications.

The Pinnacle of Engineering Excellence

Ed from Red Bull Racing’s technical partnerships team provided an insight: “Red Bull Racing created Red Bull Advanced Technologies in 2014 to leverage Formula One engineers on diverse projects, and in 2022, began developing a 1.6L V6 turbo hybrid engine, hiring 1,500 people for this initiative.”

This expansion demonstrates how motorsport engineering excellence translates into broader manufacturing applications. The technical precision required in Formula 1 provides a perfect testing ground for measurement technologies that automotive manufacturers desperately need. “We emphasise tailoring cars for each track’s specific conditions, using CAD software, simulators, and wind tunnels for precise design and testing,” Ed noted.

Speed and Precision Under Pressure

Mark Foden, Head of Quality at Red Bull Racing, illustrated the extreme agility demands that motorsport places on manufacturing systems. “Our turnaround times can be minutes, and designs are released hourly. If we’re not agile, we’re already behind.”

This level of responsiveness requires measurement and quality systems that can keep pace with rapid design iterations whilst maintaining the precision essential for both performance and regulatory compliance. “We’ve grown aggressively as an organisation,” Foden explained. “If we used the same quality levels we used on our first car, we probably wouldn’t have won the championships we have. We’ve had to evolve massively and engage the shop floor more.”

The cultural change that Red Bull Racing has embraced demonstrates how data-driven quality management transforms organisational effectiveness. “The data brings the shop floor closer to leadership,” Foden observed.

Digital Manufacturing Revolution

Dr Ingo Lindner demonstrated how the same data-intensive approach that aerospace requires could revolutionise automotive manufacturing. With nearly 20 years at Hexagon and leadership in developing the organisation’s most successful products, Lindner positioned the current technological moment as revolutionary for both sectors.

“We’re experiencing a tsunami of data generated by machines and systems operating at millisecond intervals,” Lindner explained. “This flood of information, whilst offering immense potential, also presents significant challenges in terms of data management, integration, and actionable insight extraction.”

The parallels between Formula 1’s data-intensive environment and modern automotive manufacturing are compelling. Both domains require comprehensive data collection, real-time analysis, and rapid decision-making to maintain competitive advantage.

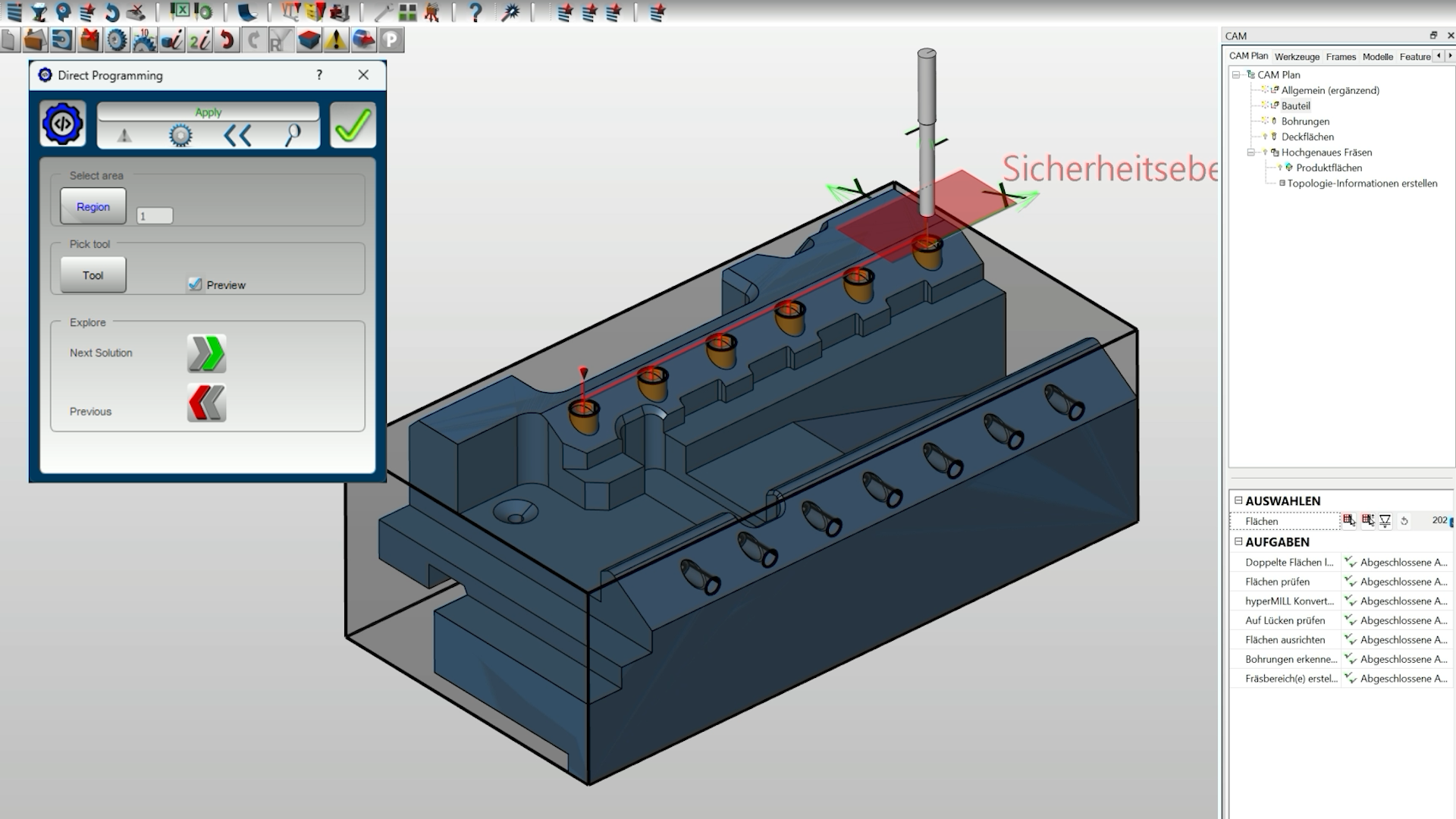

Virtual Manufacturing and Digital Twins

Lindner’s presentation highlighted how virtualisation and digital twins enable automotive manufacturers to optimise processes before physical implementation. “Virtual assembly, virtual jigs, and digital representations of factories allow manufacturers to simulate and optimise processes before physical implementation. This approach reduces costs, accelerates time-to-market, and minimises the risk of errors by enabling ‘first-time-right’ production.”

This capability proves particularly valuable in automotive manufacturing, where the cost of tooling changes and production line modifications can be enormous.

Breakthrough Measurement Technologies

The UK debut of Hexagon’s MAESTRO CMM represents a significant advancement for automotive manufacturing. Jörg Deller, General Manager Stationary Metrology devices said: “By rethinking our hardware and software from the ground up, rather than iterating on existing systems, we’ve had the freedom to create a high-accuracy inspection solution that is so intuitive that anyone from expert to new hires is significantly more productive.”

Cultural Transformation and Skills Development

The panel discussion revealed how automotive manufacturers can learn from Formula 1’s approach to rapid innovation and cultural transformation. The “fail fast, learn faster” philosophy that drives Red Bull Racing’s success offers valuable insights for automotive manufacturers seeking to accelerate development cycles whilst maintaining quality standards.

Mark Foden’s description of Red Bull Racing’s evolution demonstrates how measurement technology enables cultural change: “We’ve had to evolve massively and engage the shop floor more. The data brings the shop floor closer to leadership. Everyone understands what we’re doing and how we’re doing it, which helps them improve their processes.”

Digital Factory Transformation for Automotive

Hexagon’s Digital Factory as-a-Service offering addresses automotive manufacturing’s legacy facility challenges. Nicolas Lachaud-Bandres, Vice President Industry Solutions, explained its automotive relevance: “As manufacturers race to ramp up and modernise, they need precise, up-to-date digital context to make confident decisions.”

For automotive manufacturers adapting existing facilities for electric vehicle production or integrating new automation systems, the service provides critical spatial intelligence.

Results delivered four times faster than traditional site mapping methods, combined with 70% reduction in travel and on-site meetings, provide automotive manufacturers with the agility needed to respond rapidly to market demands.

Strategic Implementation and Market Impact

The event concluded with recognition that the automotive industry’s future success depends on embracing the precision, agility, and innovation culture that drives Formula 1 excellence. Jan Klingen’s closing remarks emphasised how technology enablement creates opportunities for sustainable competitive advantage whilst addressing workforce and productivity challenges.

The partnership between Hexagon and Oracle Red Bull Racing provides ongoing opportunities for automotive manufacturers to learn from motorsport’s approach to innovation, quality, and rapid response.