🔊Subcontractor now up to 21 Citizen lathes

The decision to set up a turned parts subcontracting business has paid dividends for Yian Stavrou and George Dingley, joint owners of Luton-based Sub-CNC Precision. Supporting their evolution from earning a few thousand pounds monthly in 2008 to turning over a predicted £3m this financial year has been continued investment in lathes supplied by Citizen Machinery UK.

The subcontractor has bought 25 machines, part-exchanging a few to leave 21 on the shop floor as of November 2025. Two-thirds are Cincom sliding-heads for producing parts from 0.5 to 38mm diameter, with the remainder being Miyano fixed-head turning centres. Many run around the clock, lights-out. In total, there are 27 CNC machine tools on site.

The introduction of Citizen’s LFV software assisted unattended machining. In 2017, Sub-CNC installed one of the first LFV machines in the country, a 20mm bar capacity L20-VIII, followed by a 12mm capacity L12-VII. Their ability to break stringy swarf into short chips meant machines could run unattended. The lathes were immediately deployed onto copper and phosphor bronze, where LFV’s chip-breaking effectiveness was especially apparent. Monel, Inconel, titanium alloys and other exotics, including for submarine components, were similarly machined reliably.

Encouraged by this success, Yian and George have ensured no new Cincom has entered their factory without LFV since then. When machining copper, LFV is switched on most of the time to prevent ribbons of swarf. It also promotes chip-breaking when turning stainless steel, aluminium and plastics including nylon, PEEK, acetal and PTFE. The function can be programmed using G-codes to switch on and off during a cycle, with different modes to adjust chip size.

George mentioned other advantages including 140-bar high-pressure coolant delivery to the cutting zone, which further assists chip breaking, especially during parting-off. The removable guide bush takes about half an hour to swap. When removed, economical use may be made of lower quality, unground bar, whilst bar remnant length is reduced, resulting in further savings.

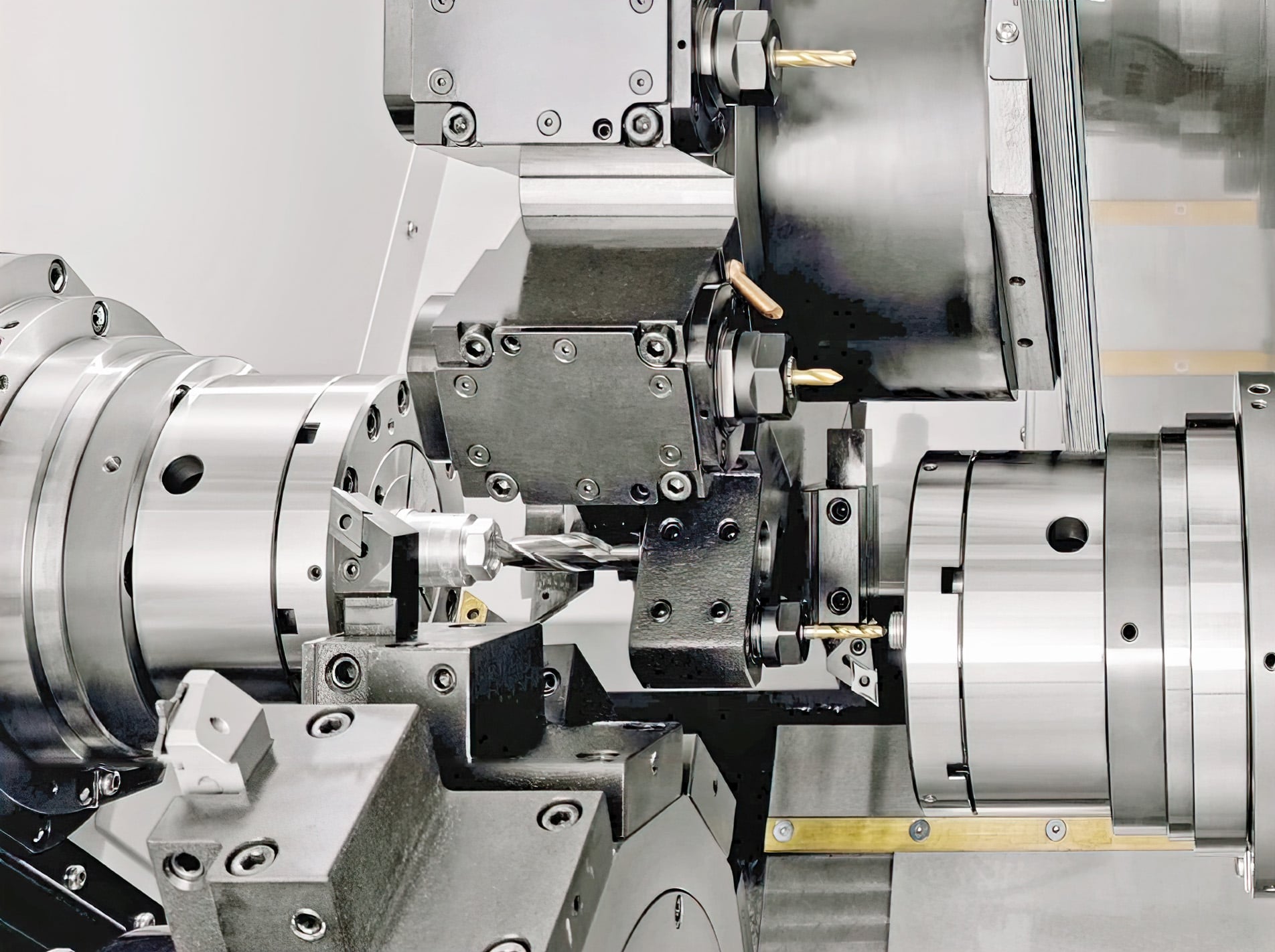

The fixed-head Miyano lathes produce parts from bar ranging from 8 to 65mm diameter, or from billet up to 200mm diameter. They started arriving in 2012 with a pair of 42mm bar capacity BNA-42MSY turning centres for complex turn-milled components in the oil and gas sector. Latest to be installed, in July 2025, was a Miyano BNE-51MSY. Three new lathes from Citizen arrived on the shop floor in the first seven months of 2025.

The BNE-51MSY was preceded in 2022 by a BNE-65MYY, extending component diameter capacity to 65mm. The lathe has Y-axis movement on both tool turrets, enabling efficient production of an aircraft component in one hit using superimposed machining with three tools in cut simultaneously. Central to operations is a well-equipped inspection room. Quality assurance begins before production with thorough review of technical drawings, continuing throughout with first-off and in-process inspections using touch-probe and optical measuring equipment. Everything is traceable from raw material receipt through to despatch.

Sub-CNC specialises in high-volume turned parts production. Recent contracts include 20,000 stainless steel automotive components weekly, 3,000 complex sensor parts weekly for utilities, and five brass components for oil and gas totalling 10,000 monthly. The subcontractor also undertakes design and prototyping followed by short runs of 10 to 20 off, often turning into long-running contracts.

In conclusion, Yian said, “We were always impressed by their performance, so choosing a Citizen lathe when setting up our business was the natural decision. If you set up a Cincom or Miyano correctly, it is practically impossible to end up with a bad part. Without adjustment, they carry on producing components hour after hour.”