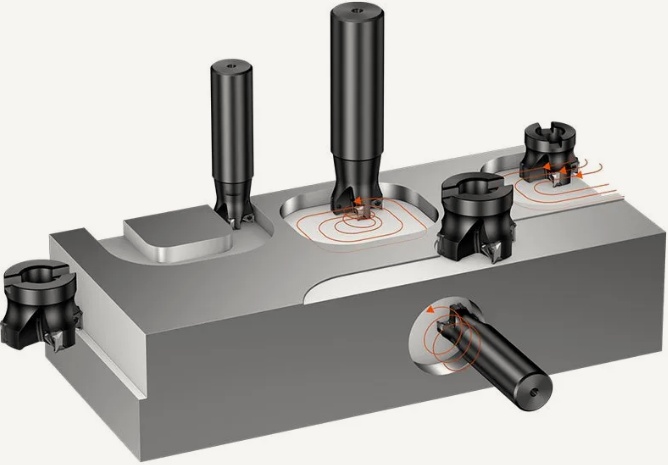

When productivity and cost efficiency are critical, CoroMill® MS60 is a solution you need to try. Designed for demanding roughing and semi-finishing operations, MS60 delivers high material removal rates while maintaining stable and predictable performance. Its robust cutter concept allows you to push machining parameters with confidence, even in tough materials and high-load applications.

CoroMill® MS60 features a unique reversible insert design with multiple cutting edges, maximizing edge utilization and significantly lowering cost per edge. This efficient use of carbide not only improves tool economy but also supports more sustainable machining by reducing material waste. Optimized insert geometry promotes smooth chip flow and controlled cutting forces, helping to protect the tool, the machine, and the workpiece.

Ideal for applications where metal removal and efficiency drive profitability, CoroMill® MS60 helps you shorten cycle times, improve output, and keep costs under control.

See the productivity gains for yourself.

You need to try CoroMill® MS60 in your own operation. Contact us today to arrange a trial and unlock high-efficiency roughing performance.