CoroMill® MS40 – Engineered for Stability, Consistency, and Control

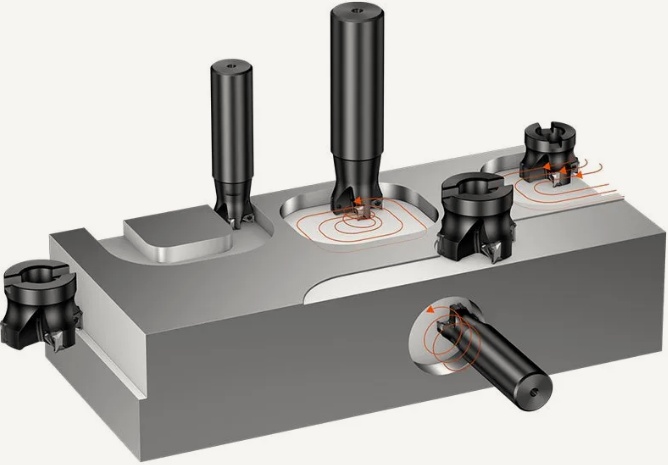

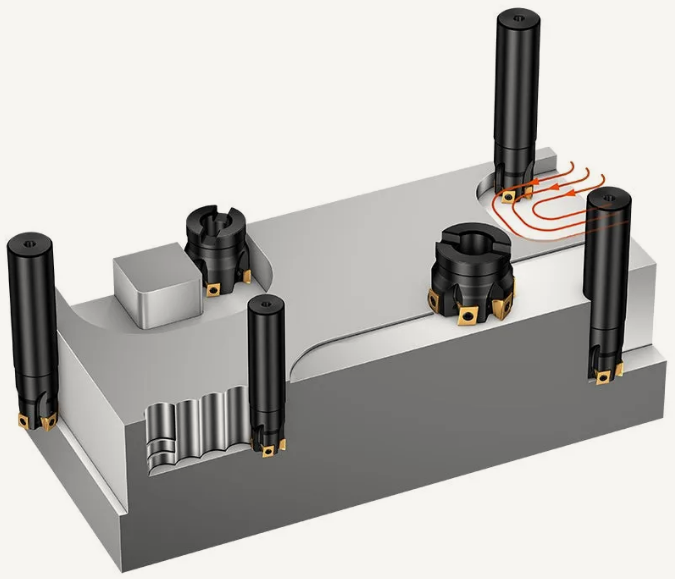

When your application requires repeated passes, long overhangs, or demanding wall machining, CoroMill® MS40 is a solution you need to try. Purpose-built for stability, MS40 features a robust tangential insert design that directs cutting forces into the cutter body, delivering superior rigidity and excellent vibration control. The result is a more stable process, tighter dimensional control, and reliable surface quality—pass after pass.

CoroMill® MS40 is designed to perform in high-load and high-duty-cycle environments. Its insert geometry and secure clamping system provide predictable tool life and consistent wear patterns, making it easier to plan tool changes and maintain uninterrupted production. With multiple cutting edges per insert, MS40 supports efficient chip removal while helping to reduce overall tooling costs.

This cutter is an ideal choice when process security is critical and variation is not an option—whether machining walls, shoulders, or complex profiles where accuracy and repeatability matter most.

Prove it in your own production.

You need to try CoroMill® MS40 to fully appreciate its stability and control. Contact us today to arrange a trial and experience reliable performance in demanding milling operations.