Mastercam has introduced a new solution for the manufacturing industry that enhances the deburring process, promising significant improvements in part quality and performance reliability. The company’s Asymmetric Edge Setting is designed to handle intricate geometries with precision, offering seamless toolpath continuity that reduces the need for manual finishing.

By integrating this advanced toolpath technology, manufacturers can achieve consistent and repeatable edge breaks. This not only enhances the aesthetic quality of the parts but also ensures their performance reliability, which is essential in high-precision manufacturing sectors.

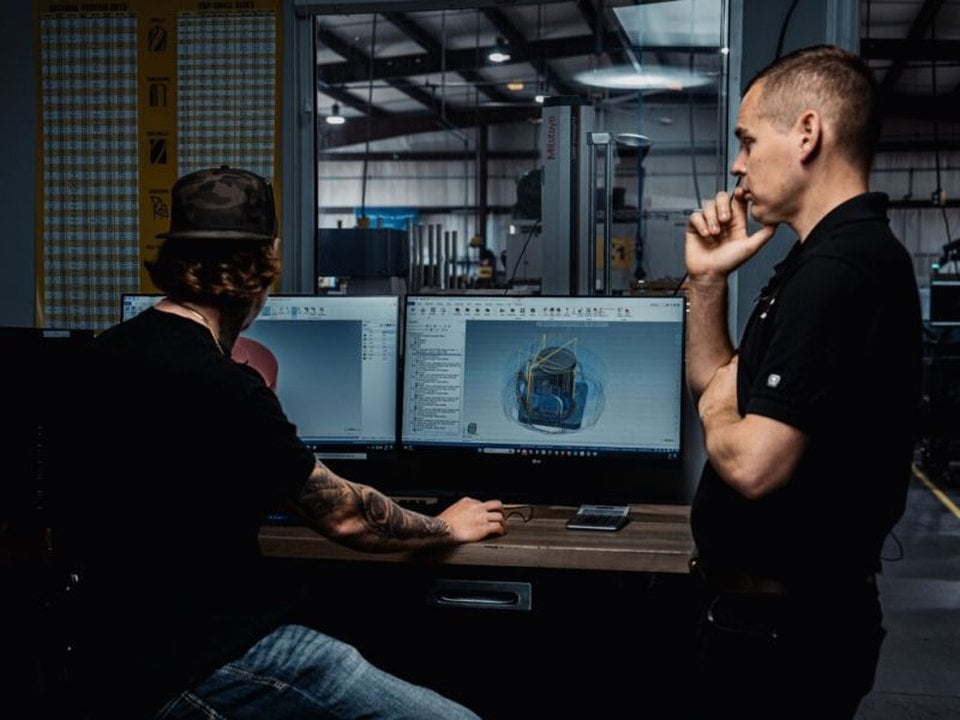

The Asymmetric Edge Setting technology by Mastercam reduces the time and labor costs associated with manual finishing processes. This technology is particularly beneficial for manufacturers working with complex designs where traditional deburring methods may fall short. With improved toolpath accuracy, manufacturers can focus on maximizing efficiency and output without compromising on part quality.

Mastercam’s commitment to innovation in the manufacturing industry is evident through continuous updates and feature enhancements. This latest advancement aligns with the company’s broader strategy to provide cutting-edge solutions that meet the evolving needs of the industry. Manufacturers utilizing Mastercam’s software suite can expect to see improvements not only in product quality but also in operational efficiency.

As the manufacturing industry increasingly moves towards automation and precision, technologies like Mastercam’s Asymmetric Edge Setting play a crucial role in setting new standards for part finishing and quality assurance.