Serving success on a pallet

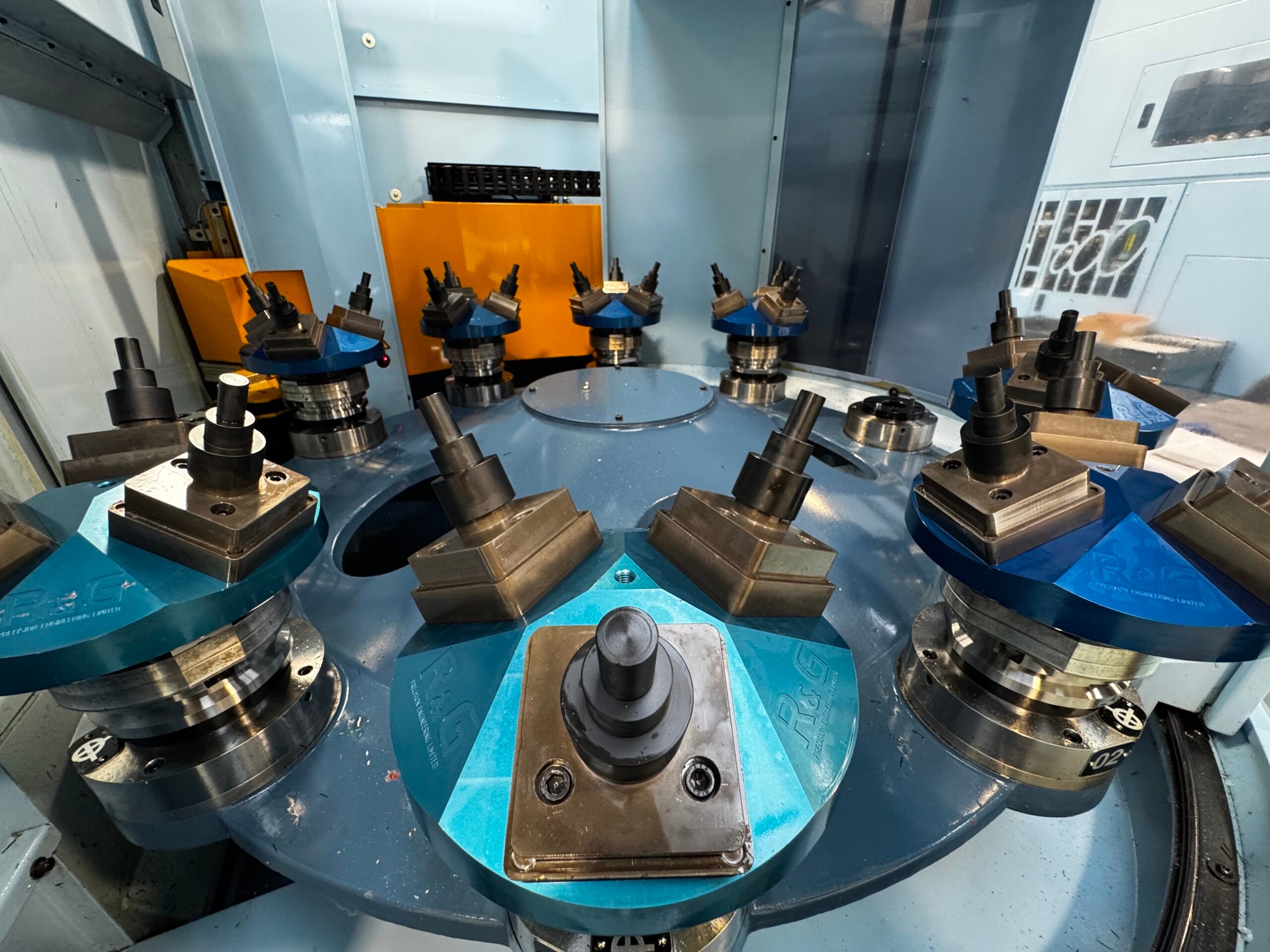

Servicing manufacturers in the medical, oil and gas, aerospace, automotive, MOD, and F1 sectors, Rushden-based R&G Precision Engineering Ltd prides itself on the level of service it delivers to its customers. To meet its clients’ tight deadlines and quality demands, the company founded 50 years ago has invested in a series of multi-pallet machining centres from Matsuura.

However, the shop floor at R&G Precision looked different four years ago from how it is today. Enzo Chiarelli from R&G Precision Engineering Ltd says: “We recall looking back to our first multi-pallet lights out machine and thinking back to when we were first looking at it – we were thinking ‘this is never going to work’. Now, we are predominantly lights-out multi-pallet machining, and the plan for the next 3-4 years is to swap more single spindle and single pallet machines for the multi-pallet variants.”

“It’s nice to sit at home now and think, ‘I am making money.’ With the RiMM software, you can control that. So, when your team says the machine was running all night, you can come in and look at the RiMM system and say – oh yeah, it was running at 2am this morning.”

Thinking back to 2020, Enzo recalls: “I remember thinking, ‘What have I done? It’s such a big investment with lights-out machining. It’s worked, and it’s a journey we’re so glad we started. It’s exciting and gives us a vision of where next.”

With a machine shop filled with Matsuura machines like the MX330, the company was nervous about diving into ‘lights-out’ machining. Recalling what the company has learnt, Enzo says: “I did a lot of research, we had to weigh up the pros and cons. The pros are running when nobody is here with multiple set-ups. The cons are all around making sure you got the process right – as you can have tool breakages, blockages, you could have coolant issues and a multitude of other variables – and that is always a worry.”

“We also had to think ‘how do you start’ – do you go slowly and build up or go in straight at the top? However, it was all about learning from the first machine for us and learning about how to get to a complete lights-out process that gives you the confidence to say, ‘OK, I know what I’m doing now. I have to prove out every job during the day for 2 to 3 weeks before swapping out and making the switch – and that is what we did.”

Now with 8 Matsuura machines, Enzo recalls the first machine: “That was an ES-450HII machine that is still running, and for us, that was an investment in a company that we’d never done business with before. The sales rep pushed me towards lights-out machining, which is how we got to eight machines.”

The company progressed to buying the Matsuura MX330 multi-pallet machines acquired for a batch of work the company had at that time. However, that was two years ago, and the company has since changed direction. As Enzo adds: “The Matsuura MX330 machines were bought for smaller components in repeat orders we were doing at that time. That work increased, so we bought a second MX330 with 10 pallets. However, Dominic from Matsuura asked us why another MX330 was needed.”

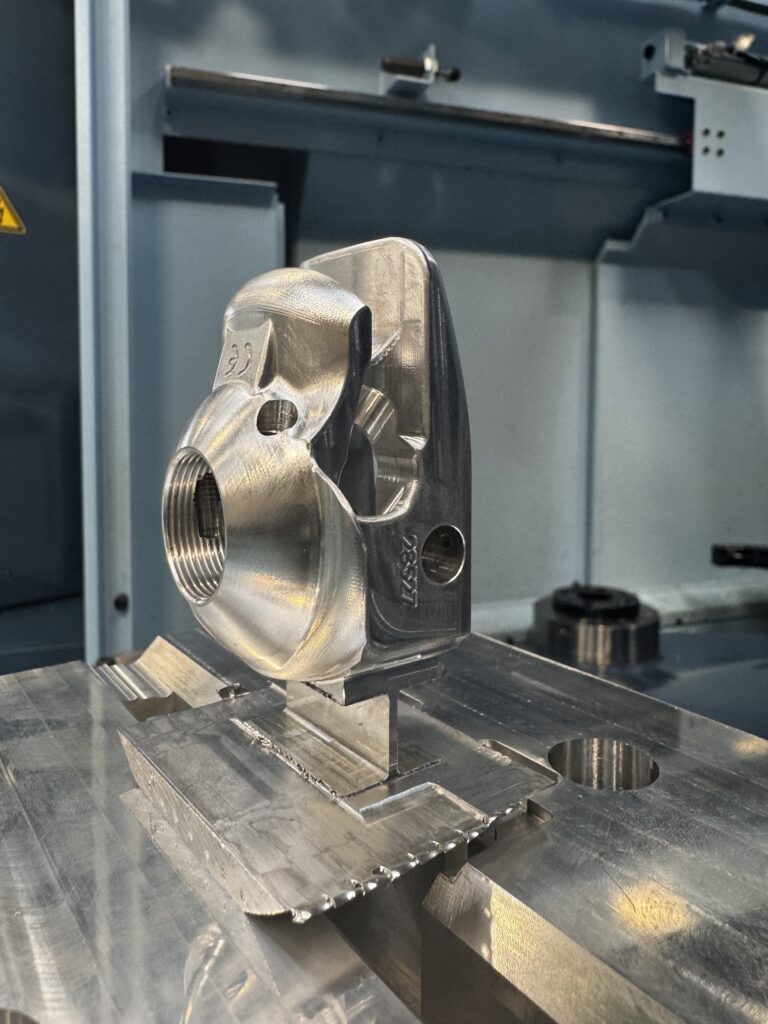

“We sat down and showed Matsuura the portfolio of parts in the pipeline, and he instantly said no, you need a MAM. So, we purchased a MAM72-63V, and it worked. Now, we will continually show Matsuura the portfolio of parts we have, and they will tell us what machine to buy – and it works well.”

“The contract we bought the MX machines for is completely separate from a new contract that has arrived. The first contract ran for four years and continues to run, where we machine repeat orders for 50 to 100 parts a month. The other contract we had to invest in with another five Matsuuras is a 15-year aerospace contract that will run until 2035. That is a contract where I sat with Dominic and said, ‘You have to advise me on whether we need to invest in the MX range, the MAM machines or other models.’ I’m glad we took his advice, we opted for a MAM35 and a MAM63, which also gave us a size difference. On the MAM63 machine, we can do larger parts and a mix of smaller parts. On the multi-pallet machine, we can do everything, and we have no downtime at all.”