Emuge-Franken Expands Solid Carbide Drill Portfolio for Superior Holemaking Performance!

By Ashutosh Arora

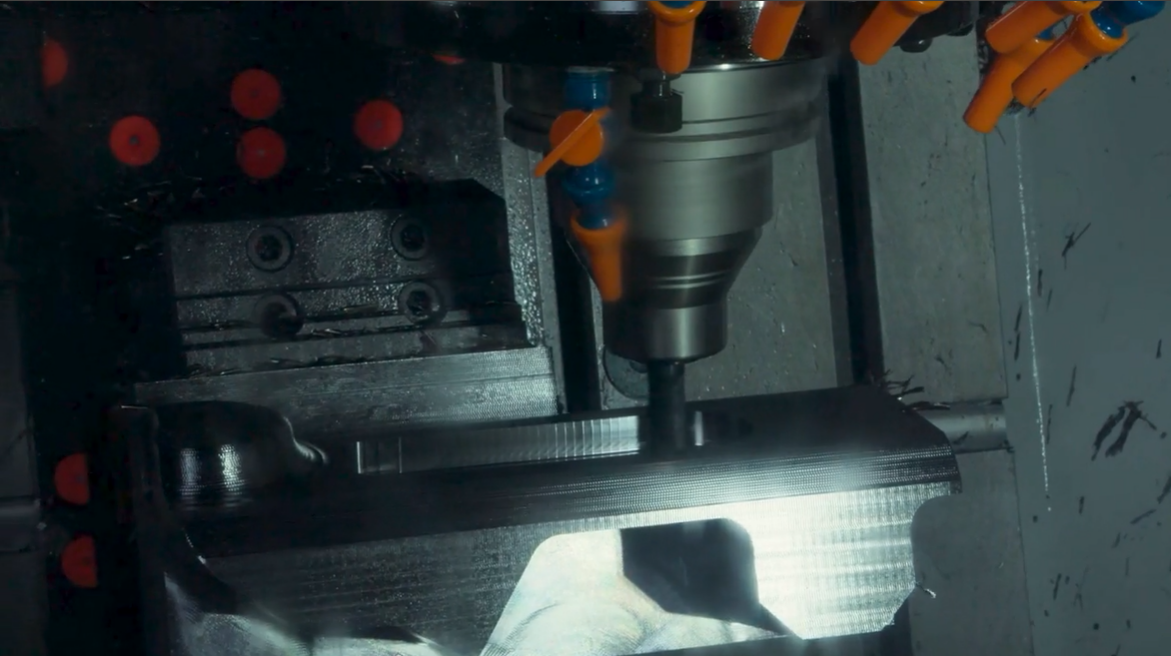

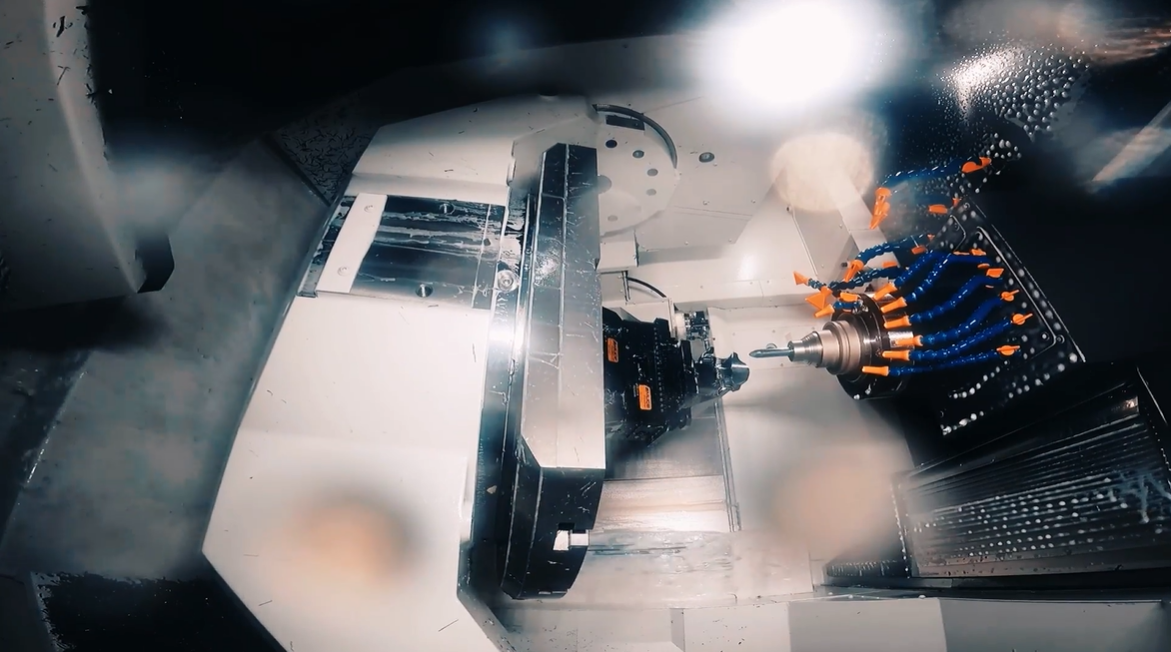

Emuge-Franken USA has significantly expanded its solid carbide drilling solutions with the introduction of new drill lines—SteelDrill and InoxDrill—alongside enhancements to its existing MultiDrill and EF-Drill series. These latest additions are engineered to deliver high-precision hole quality across a broad spectrum of materials and machining applications, reinforcing Emuge-Franken’s commitment to innovation in cutting tool technology.

The newly launched SteelDrill line is optimized for steel and cast materials, but is also capable of handling hard and nonferrous metals. The drills feature a concave primary cutting edge, through-coolant capability, and a double-margin design that ensures superior stability and consistent hole precision. With a specialized coating that promotes smooth high-speed cutting and long tool life, SteelDrill is available in 3×D, 5×D, and 8×D lengths, with diameters ranging from 3.00 mm to 20.00 mm (0.1181″ to 0.7874″).

For machining tougher and stickier materials, the new InoxDrill line is designed specifically for stainless steel, titanium, nickel alloys, and aluminum. It features a single-margin design to minimize material adhesion and improve guidance, and benefits from Emuge’s proprietary coating and polishing process for enhanced performance. InoxDrill also includes through-coolant functionality and optimized edge preparation for efficient drilling. The drills are available in 3×D and 5×D lengths, with diameters from 3.00 mm to 19.05 mm (0.1181″ to 0.7500″).

Emuge-Franken has also extended its MultiDrill line, now offering 8×D length drills in diameters from 3.00 mm to 16.00 mm (0.1181″ to 0.6299″). The MultiDrill Micro Drills lineup is bolstered with 6×D micro drills, featuring diameters from 1.00 mm to 2.95 mm (0.0394″ to 0.1160″). These micro drills include an advanced flute profile for superior chip evacuation and a radius cutting edge for optimal shearing. The specialized ALCR-99 coating provides exceptional heat and wear resistance, while a unique point geometry helps generate short chips and enhances drilling efficiency across varied materials.

To address the demands of deep hole drilling, the company’s EF-Drill series has been expanded to include 12×D drills in diameters ranging from 3.00 mm to 14.00 mm (0.1181″ to 0.5512″). These drills are designed for applications requiring tight straightness tolerances and premium surface finish, offering reliable performance in challenging machining conditions.

With this expanded drill portfolio, Emuge-Franken provides machinists and manufacturers with an exceptional array of precision holemaking tools tailored for a wide range of materials, part geometries, and depth requirements. The integration of advanced coatings, cutting geometries, and coolant technologies makes these tools ideal for aerospace, medical, automotive, and general engineering sectors where hole quality and tool performance are critical.