🎧 – What is industrial metrology?

More importantly, what should industry metrologists be doing to be effective and of good value to a business? To answer that question is not as simple as you may think. The purists will say metrology is pure science, set out with trusted and consistent tools and practices. In most metrology roles they are right, but add the word ‘industrial’, in front of metrology and now we start to hit vagaries. By Ian Wilcox

In this first of a two part article, we will look at the different types of metrology, and how those types can differ due to the organisational mission, expected outcomes and therefore motivation and business necessity. The industrial landscape can make its version of metrology more ambiguous.

In the next issue of MTD magazine, we will publish the second part of this article. In part 2, I will give some insight into how industrial metrology can work for a company; what can be done, how it can provide benefit and how to navigate through those vagaries.

Let’s start with some definitions that come from the top. In this case, the top is a definition published by the International Bureau of Weights and Measures (BIPM), they state that there are three types of metrology.

-Scientific Metrology

-Applied Metrology

-Legal Metrology

A simplified description of each would be:

Scientific Metrology

As the name suggests this type of metrology follows the pursuit of scientific advancement. With clear, unfettered and focused goals to advance knowledge, capability, and the realisation of internationally agreed frameworks of the units of measurement – setting specifications for standards and their application. Embedding them into their regional or national economies via stakeholders such as governmental departments and licensees, scientific bodies including technology manufacturers, industry and ultimately society. Scientific metrology forms the foundation for the other aspects of metrology that follow.

Technical Metrology

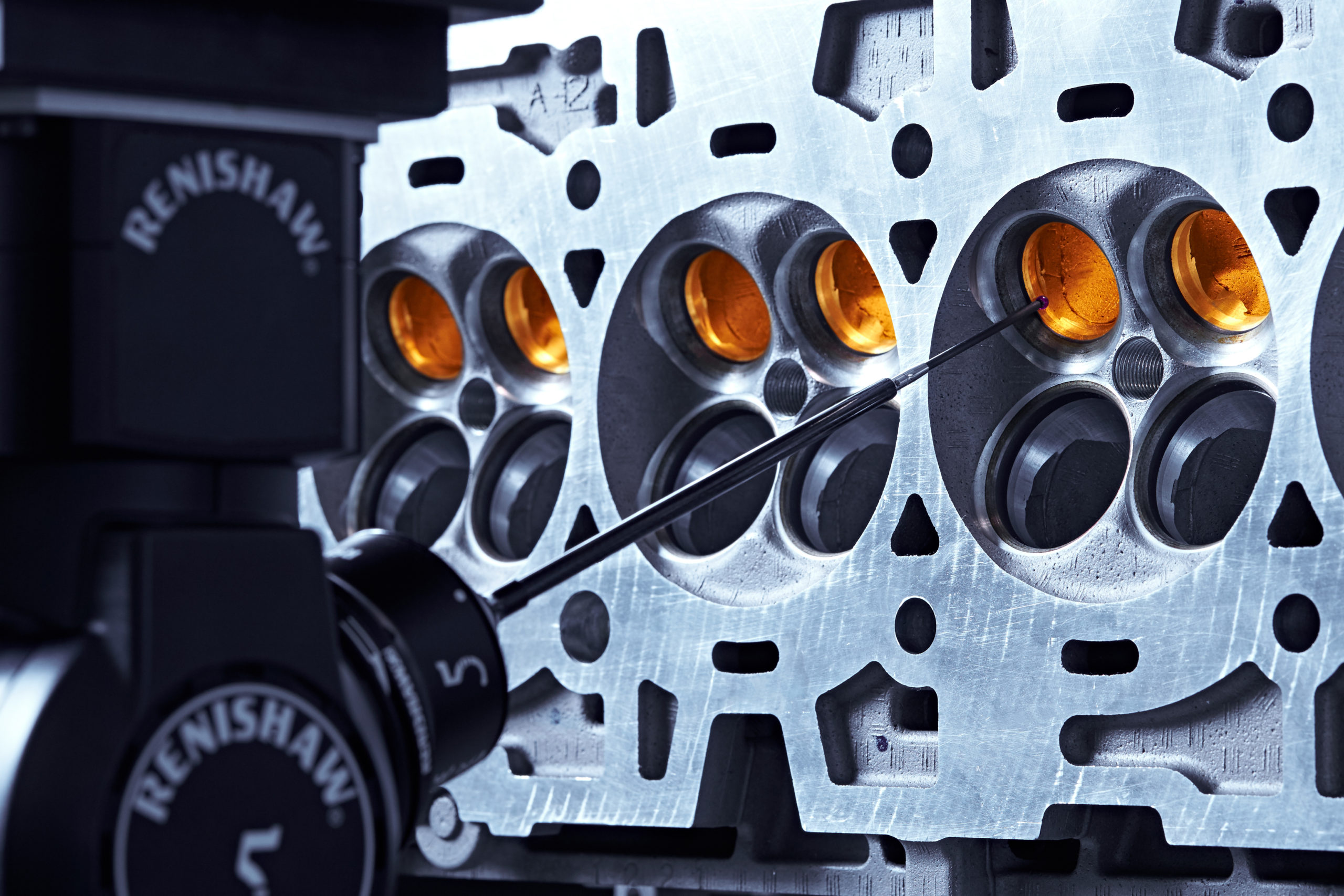

Also known as Applied Metrology. This deals with the end use of measurement and its application, including but not exclusively, industrial and manufacturing processes. A stream within technical metrology supports industrial and other non-industrial applied metrology such as calibration and verification.

Legal Metrology

This relates to law and regulation, both national and international to ensure fair trade. This also constitutes other areas where metrology provides assurance of compliance and where applicable, safety. Providing impartial transparency in measurement and equipment capability, legal metrology protects traders, consumers and the wider public.

Both scientific and legal metrology are well-defined, independently regulated, audited heavily and often peer-reviewed. They also have a quality function that is focused almost exclusively on a good metrology outcome. Metrology is their purpose, its service and advancement are their output. Being heavily audited and regulated leaves individual organisations very little wiggle room in how their metrology can deviate. Often your license or contract to deliver can be revoked if you do not comply with the set standards.

Contrast that with industrial metrology as applied in manufacturing. Metrology practices are not usually specified or independently regulated, specific requirements if any, are set by the purchasing company in a supply chain contract. Alternately, requirements can be specified whereby individual companies are masters of their own metrology (or lack of) if it is not customer specified. Supply contracts may have some generic requirements, but these are often vague on metrology specific activities and mainly focused on higher quality metrics.

Some large ‘prime’ or top of the supply chain companies do set out metrology-related requirements but these vary widely. Some industry sector initiatives also exist but can suffer from a lack of take up and/or funding. Examples of where these can be found are in medical device manufacturing. Anything made with an airworthiness certificate and other safety-critical parts such as brake components on a vehicle. In these cases, managing quality with more stringent and specific metrology practices may be specified, or at least implied.

But outside of those examples and far more common across the broad spectrum of industry, is that each manufacturer is unregulated and left to create their own ad-hoc approach to metrology and measurement strategies. Or when companies are unfamiliar with what metrology is, they miss it out completely and just measure in blind faith that technology and calibration is enough.

I must raise and recognise that a stream within technical metrology is also tightly regulated and audited, and that is calibration and verification. Requiring compliance to ISO:17025, a quality standard that is a must, if you want to offer calibration services. It is a standard that specifies metrology tools and evidence of completion of metrology activities. Their processes are also keenly audited and assured. Calibration gives assurance, and compliance and sets benchmarks that provide the opportunity for manufacturers and supply chains to be comparable and therefore collaborate and subsequently trade. As a manufacturer though, do not assume your metrology can be managed simply through calibration.

If you are a manufacturer and in that third area of Technical Metrology, ask yourself what requirements you adhere to regarding actual measurement strategies and metrology practices. Not Quality but Metrology.

Is Industrial Metrology the ‘Wild West’ that I paint here? I should and can temper the ‘Wild West’ analogy because even in Wild West America there was a Washington, a San Francisco and other places where higher standards were applied. Some of you will feel that this is not the world you occupy or recognise, and to varying degrees I accept that there are some good industrial metrology practices out there. But a significant number of manufacturing companies have lost their way on metrology.

With little clear guidance on company-level metrology strategies and their benefits, skills not keeping up with modern manufacturing, and add to that a measurement technology explosion that exacerbates the ever-widening gap between metrology good practice with its productivity benefits – the actual reality is that has an often-undiagnosed drag on productivity. That may sound harsh to some, but based on my own experience dealing with manufacturers from SMEs to big international household names, a lot of you will recognise elements of what I am trying to say.

Good measurement is a must for companies. Good measurement just doesn’t happen, you must manage it. You need the insights gleaned from metrology activities to make better decisions around measurement strategies. Metrology can give you this insight. Once you have reliable measurement data and process control, lean and other productivity related activities are boosted by confidence in reliable data.

In the next issue, I will switch to what you can do and what benefits can be achieved. In other words, how to reap the productivity bonus. Be more Washington and San Francisco than Tombstone and Deadwood.