🎧 – Don’t prepare for audit – Live it

Nottingham-based manufacturer Vestatec UK recently renewed its IATF 16949 certification with no minor or major non-compliances. Known in the automotive industry as ‘the double zero’, David Marriott, Quality Manager at Vestatec, discusses how Vestatec’s approach to quality helped them to attain this rare and magic number.

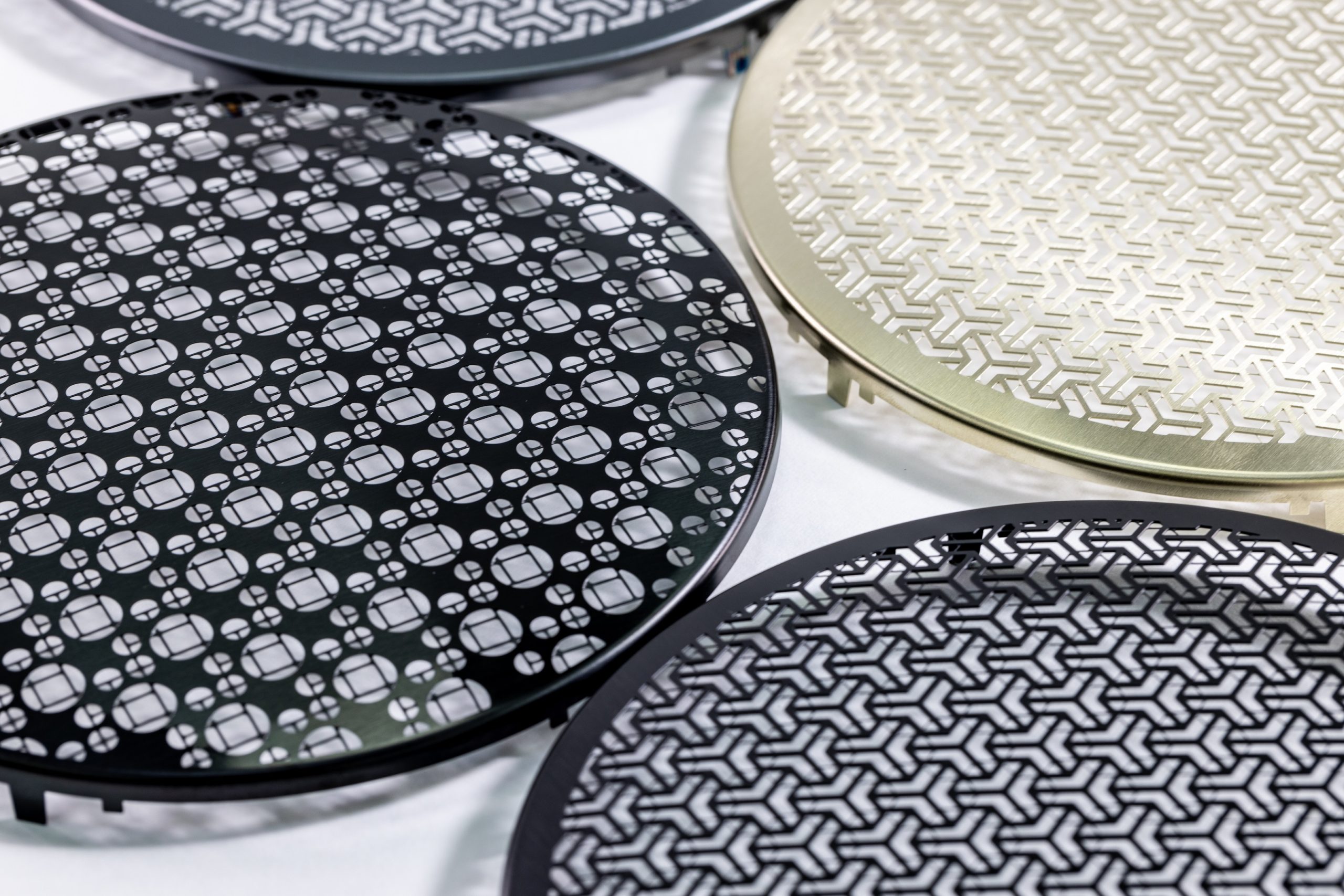

As a supplier to the automotive industry for over 35 years, Vestatec is trusted by leading brands from Rolls Royce and Ferrari to Volvo and General Motors. While having the ability to manufacture across a variety of sectors, Vestatec’s core business lies primarily in the end-to-end manufacturing of interior trim, speaker grilles and styling solutions for luxury vehicles.

As a supplier to the automotive industry for over 35 years, Vestatec is trusted by leading brands from Rolls Royce and Ferrari to Volvo and General Motors. While having the ability to manufacture across a variety of sectors, Vestatec’s core business lies primarily in the end-to-end manufacturing of interior trim, speaker grilles and styling solutions for luxury vehicles.

For Vestatec, the IATF 16949 certification is crucial in demonstrating to customers that our people and processes are set up in a way where we can reliably deliver projects, however specific, challenging, or detailed – and regardless of volume.

Originally developed by American carmakers to improve reliability, reduce risk and driving continual improvement for the industry, the IATF 16949 certification takes ISO:9001 a step further for automotive suppliers. It is focused on driving forward product quality by mitigating all manner of process capability issues that could result in defects, inconsistency, excess waste and supply chain disruption.

In our most recent audit, we proudly achieved zero major or minor non-compliances, which is rare by any stretch of the imagination.

In our most recent audit, we proudly achieved zero major or minor non-compliances, which is rare by any stretch of the imagination.

Driven by detail

When asked how we achieved it, there are several answers. But the honest answer is that we didn’t prepare for it. Instead, we live it. By becoming familiar with the requirements of the IATF certification, we can ensure that processes are continually monitored, and improved upon where possible. Achieving impeccable quality and meeting the stringent demands of the automotive sector can’t be achieved in weeks, or even months. The IATF audit is all-encompassing, and it is impossible to pull the wool over an auditor’s eyes. These people are specialists that can sniff out non-compliant processes a mile away.

The audit consists of over 40 pages of criteria looking at all aspects of management, from product development and design to process capabilities and manufacturing control. There is also a big emphasis on the products themselves, looking at the processes that could potentially affect the product throughout its lifetime.

Our customers often seek to create truly unique design solutions. Through our capabilities and attention to detail, we are helping customers improve user experience, and add brand differentiation and financial value at every step. We do this by ensuring repeatability of precision and quality, for both low and high volume. Creating this detail requires a commitment to quality that must be ingrained into every process and operator.

Cross-company collaboration

In the 1960s, President John F. Kennedy visited NASA. When he asked the cleaner what role he played, he famously replied, “I’m helping to put a man on the moon.” It’s this sort of approach we take at Vestatec. We ensure that all our staff understand their role within the company and also the purpose and result of their work. Everyone must share our vision.

In automotive parts production, there is little room for error. Every rejection or failure impacts our parts per million (PPM) scores, a standardised KPI which measures quality performance by measuring how many defects exist within every 1 million parts produced.

For our business, one of the key components to driving quality and keeping PPM as low as possible has been our drive to involve staff at every level in our ambitions for improved processes and educating them on why they are important.

Every one of our employees, either directly or indirectly, is critical to the quality of the components we produce, as well as playing an active role in the auditing process. We ensure all customer portal scores are shared across the entire business, so our shop floor staff can see the impact of their hard work and also identify areas of improvement.

As part of our IATF 16949 audit, all staff are asked to explain our processes. By ensuring ‘buy-in’ to the standards we work to, all staff can passionately and proudly present what they do. If you have operators that are nervous or unsure about what they do, it’s reflected in their final product. Only through thorough engagement throughout the entire process have we been able to realise rock-solid performance scores with our customers.

Customer and supplier engagement

Our suppliers and customers play a key role in the quality of our components. Having the strongest possible relationships and ensuring suppliers are aware of our commitments to quality means they can be transparent with any problems that may lead to defects. Even though IATF 16949 doesn’t mandate it, we also audit suppliers regularly; through the great relationships we’ve built with them, we can continue to operate with a high degree of trust.

For customers, we ask that any defects or inconsistencies are reported to us immediately. Instant replies to customers are mandatory in our organisation so we can take swift action to identify the problem without major issues.

With vehicle manufacturing and delivering parts to trackside, late replies or lack of transparency can present a huge problem. But if you have the right relationship with your customers, it can make life a lot easier. If customers have confidence in you as a supplier, issues can be managed rationally and professionally.

The personal touch

The nature of what we produce means there is a subjective human assessment of quality – bringing quality into the realms of opinion. With aesthetic products like interior trim, a human still needs to make a judgement. This is not as easy as reading a measurement off a dial as one would when producing a component like a nut or a bolt with a tolerance of ±0.01mm. So, in addition to digital inspections, we also incorporate human inspection into our quality assessments. Be it a 20-second visual inspection from half a metre away, we can safely say there is nothing there that shouldn’t be there.

Our work is complex. We often take on projects that other suppliers wouldn’t risk, therefore sometimes defects are a given. One way we manage this expectation is to complete a thorough pre-production approval process.

Before we enter the production stage of any project, we will prototype and test performance to identify any risk of defects. We always advise customers where we foresee potential issues. As such, we’ve never had a dimensional issue that we haven’t known about and communicated to the customer during the pre-production phase. This detailed level of quality and transparency with clients means that we achieve 0 PPM scores on many of our projects.

For us, quality is at the heart of everything we do and goes far beyond tensile, bend and impact testing. True quality lies in collaboration, transparency and consistent commitment at every level of the business.