For more than 50 years, Quickgrind has been a company revered as an industry leader in the solid carbide cutting tool space. Now, the Tewkesbury manufacturer has launched a new product line – and it’s a modular range of cutting tools.

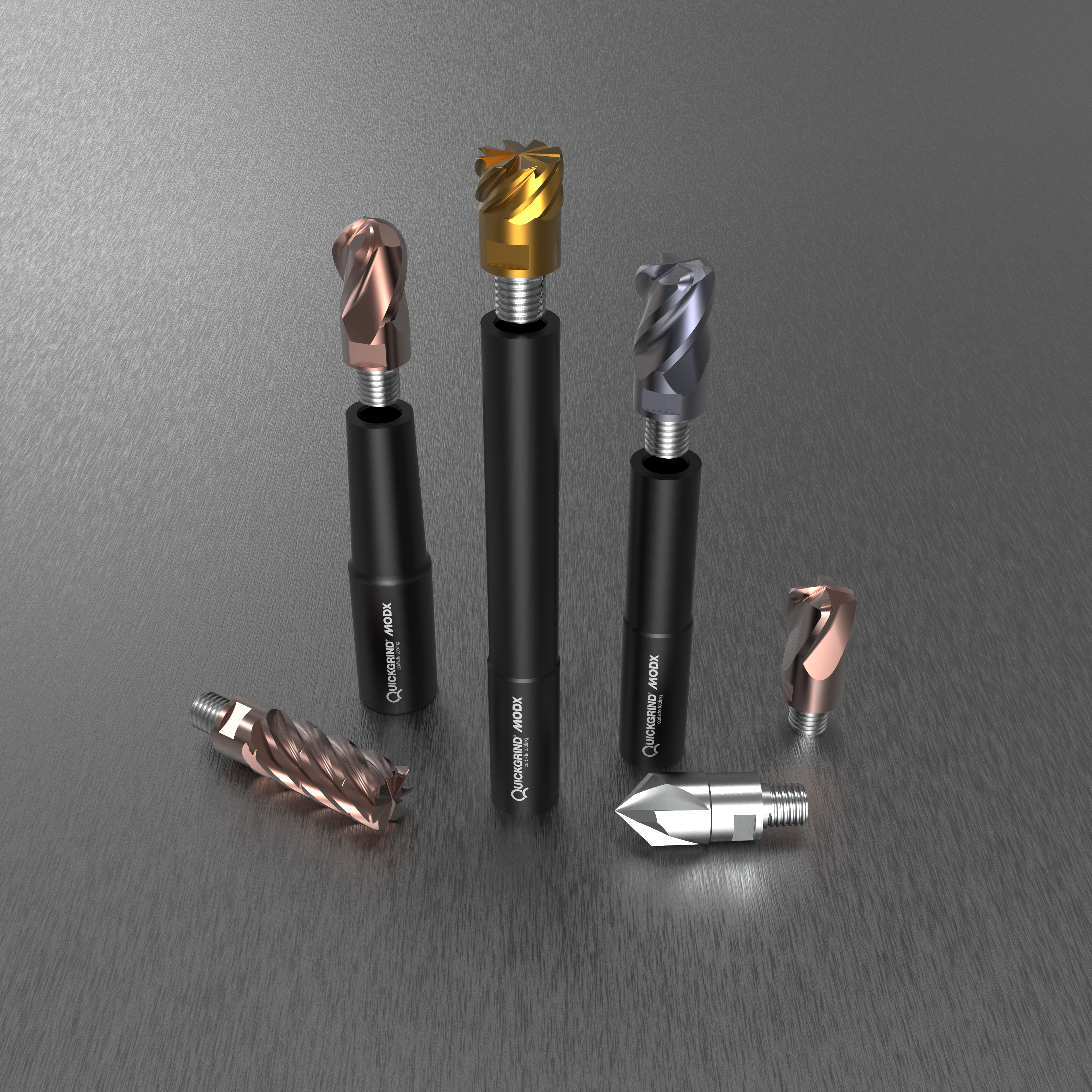

The new ModX series from Quickgrind is in response to the ever-evolving demands of the marketplace for an expanded range of machining solutions – and as a company with the ‘Infinite Possibilities’ ethos, Quickgrind has responded with a product line that once again exceeds the realms of what is possible from rival cutting tool manufacturers. Combining the performance and durability of its solid carbide range with the modularity of interchangeable head tooling, the new ModX provides machine shops with the blend of flexibility and performance.

From a quality perspective, the carbide shanks are manufactured to a 2µm runout tolerance for reliable precision machining. The modular, high-quality carbide tool shanks present superior rigidity than steel alternatives, and the shanks can also be stepped or tapered to the customer requirements. The tool shanks also incorporate the company’s innovative locking mechanism ensuring maximum coupling stability. Existing Quickgrind customers familiar with the ‘Infinite Possibilities’ ethos will certainly be interested in considering the potential benefits of this system. For manufacturers new to Quickgrind’s ‘Infinite Possibilities’ means that the tool dimensions and type can be specified to meet the exact requirements of your business – there are no set dimension parameters here.

Connecting to the solid carbide shank is the modular cutting head. Once again, Quickgrind is keen to stress the ‘Infinite Possibilities’ programme and its unfathomable depth of options. Each modular head has a face and taper connection that creates a secure connection with the tool shank for maximum strength and performance. To secure the head in the shank, the ModX series has a physical stop that indicates when the head is correctly tightened.

With the changeable heads, this is where the range of opportunities becomes apparent. Customers can select the head length, diameter, tolerance, number of flutes, helix angle, anti-vibration, coating and more. The ‘Infinite Possibilities’ stretch through a complete range of options with end mills, ball-nosed end mills, barrel tools, roughing end mills, aluminium cutters, high-feed end mills and chamfer tools.

Within this selection band, the options expand further. For example, the end mills can be chosen with 2 to 7 flutes and a choice of coatings and geometries for all types of materials and applications. This also applies to the roughing end mills that have flat-crested geometry and variable helix options to enhance performance when undertaking trochoidal machining strategies.

The ball-nose tools are offered with various flute counts and a selection of lengths and coatings to enhance chip flow and wear resistance; likewise, the aluminium heads have 2 or 3 flute options, square or ball nose and roughing heads for a complete range of aluminium alloys. As a pioneer in the development of barrel tools, Quickgrind has also introduced a range of interchangeable conical, lens, tangential and type-F heads for finish and semi-finish machining strategies that can reduce cycle times by up to 90%. Complementing the barrel tools is a series of high-feed end mill heads with 3 to 5 flutes with precision ground geometries that reduce cutting forces and maximise swarf evacuation to improve productivity by up to 60%.

For manufacturers that would like to investigate the ModX range of possibilities, the system’s simplicity is that manufacturers can select the shank length and diameter and then pick the neck specification. Once these parameters are chosen, customers can select the modular cutting head specification. With ‘Infinite Possibilities’, Quickgrind is inviting manufacturers to discuss the limitless opportunities that are available with the new ModX series.