Front of the Q

With its ‘Infinite Possibilities’ cutting tool philosophy, Quickgrind is an industry leader in bespoke cutting tool solutions. Now, to support the ‘Infinite Possibilities’ ethos, the Tewkesbury manufacturer has introduced its new ‘Q’ Series of standardised end mills.

As a company that delivers solutions for the challenges of the industry, Quickgrind already had more than 120 different product items in its standard range that complement the specialist tools. However, the new ‘Q’ Series adds a completely new lineup, taking the standard lines to more than 400 items.

Providing a tool for every application, the new additions to the standard line-up include the new QPlus2 range of 4-flute 30-degree helix MX coated end mills with a variable index geometry for machining a wide range of materials. The sharp corner geometry makes it a preferred choice when trying to achieve a square edge. Ranging from 1 to 20mm in diameter with tools from 1 to 6mm available in 0.5mm increments, the series is also available with additional extended reach. This comes in the form of the QPlus2-LS which is available from 3 to 20mm in diameter. This extension to the 4-flute 30-degree helix MX coated long series end mill makes it suitable for reaching into cavities and other surfaces where reach and rigidity can be a challenge.

Also new is the QBall, a 4-flute MX coated ball nose tool with a variable index. Perfect for profiling, this range is available from 1 to 20mm diameter with increments in line with the QPlus2 series. Complementing the QBall is the exemplary new QChamfer. This 4-flute 90 degree CX Plus coated chamfer mill is suitable for a diverse range of materials and is ideal for chamfering, countersinking and spot drilling; making this a universal solution for end users.

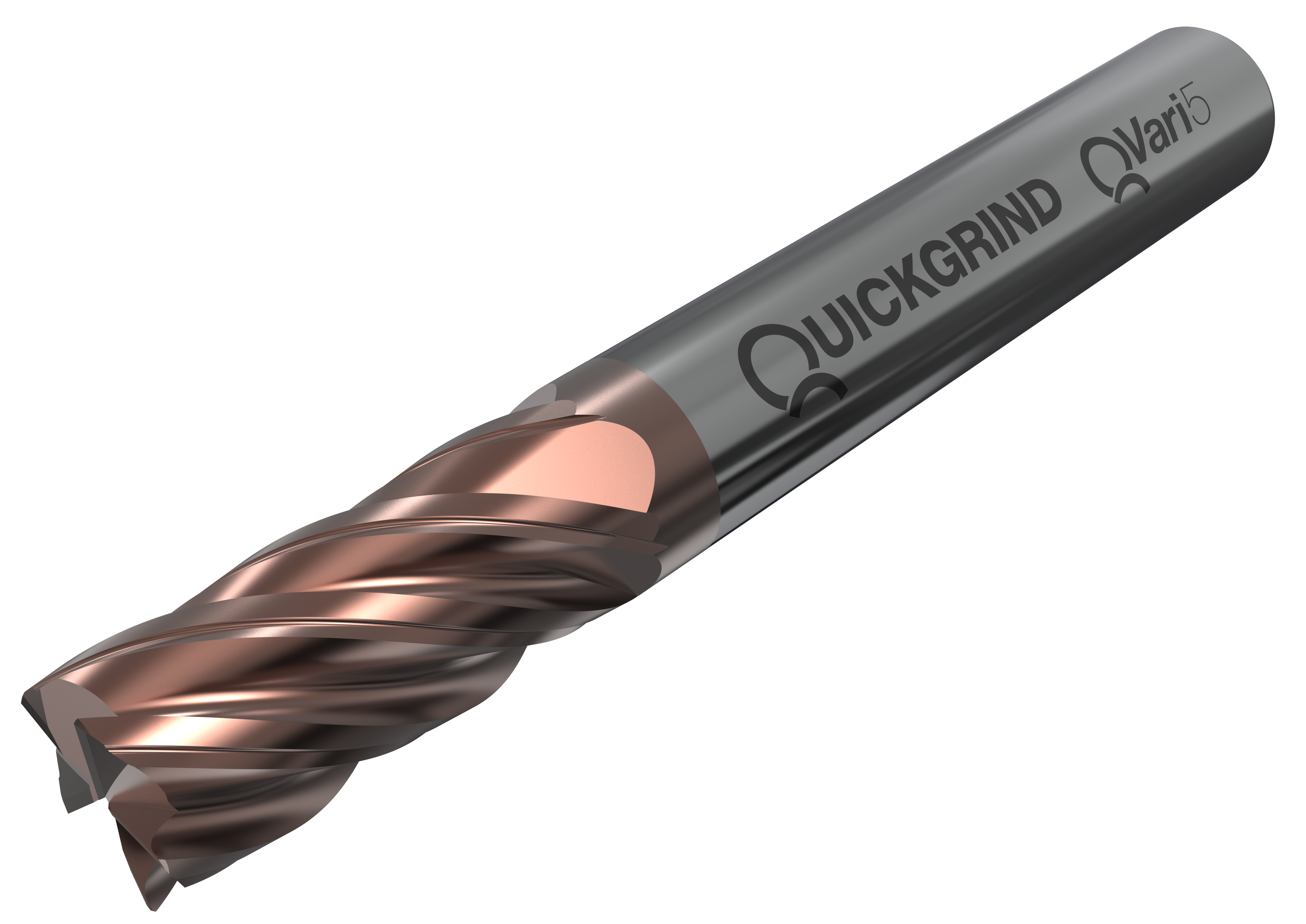

For high-performance machining, Quickgrind has unleashed the new QVari. Available with 4, 5, or 7 flutes, the QVari has a variable helix and design with X-Red coating that makes it an astute choice for roughing and finishing with one tool. It is suitable for both conventional or trochoidal machining strategies. The QVari is also available with another variant, the QVari CR. This is available with a corner radius for profiling components. The quality carbide and coating make it suitable for machining steels and HRSA type materials. The QVari is also offered with a long series version from 6 to 20mm diameter to ensure that high performance can be attained on all types of components. When it comes to trochoidal milling strategies and high-performance cutting, the 5 and 7-flute variants are Quickgrind’s first choice performers.

Completing the new product range is the QAlu. Available with three variants that include the QAlu, QAlu-CR and QAlu-R, this 3-flute 40 degree helix tool with polished flutes and 3 teeth provides balanced HSM when machining aluminium and non-ferrous materials. The QAlu and QAlu-CR tools can be used for both roughing and finishing applications at high speeds and feed due to the geometry. Suitable for either conventional or trochoidal machining strategies, the series is offered in a diameter range from 3 to 20mm. Each tool has a specific purpose with the QAlu-CR suited for both roughing and finishing applications at higher speeds and feeds due to its geometry. Suitable for either conventional or trochoidal machining strategies with a wide range of corner radii for each diameter, this tool is suitable for machining aerospace-type parts. Complementing the QAlu-CR is the QAlu-R roughing tool with an NF flat created geometry and TX-R coating for use in both conventional or trochoidal machining strategies with increased material removal rates.