To celebrate the opening of its new showroom, Hexagon hosted a launch event at the end of September. Exclusively hosted for customers and members of the press, the event presented all of the very latest technology that enables manufacturers to take complete control of all the key stages of their manufacturing processes – from the design concept through to the finished component. MTD magazine went along to find out more.

Hexagon has an unfathomably extensive portfolio of digital manufacturing technologies that span everything from CAE solutions for design and engineering, CAD/CAM and production software, metrology hardware and software as well as data management and analytical tools. Now, with the opening of the new facility, manufacturers can visit the showroom and receive demonstrations and technical application support.

Giving his perspective on the event, John Drover from Hexagon says: “We’ve had a gap of several years during the pandemic, this event and our new showroom is a chance to reintroduce our customers to the latest products and build upon our relationships. We can now have our customers see our technologies on-site in our new showroom and share our journey. We aim to take customers through the entire manufacturing journey. As a family of businesses that are unique in our offering, we have a complete suite of interlinked solutions and at our new showroom, we can demonstrate this.”

Like the unfathomably diverse Hexagon portfolio, the new showroom caters for the expansive needs of the industry with six different product stations. One station encapsulates the potential of the Hexagon portable measuring range with the Leica Absolute Tracker AT960 MR. The AT960 MR offers 3D measurement volume up to 40m in diameter with 6 degrees of Freedom (6DoF) measuring volume up to 20m diameter. The robust laser tracker provides high-speed dynamic measurement as standard. Looking at tracking technology at the event, MTD spoke with Andrew Yeomans, the Managing Director of A-MET Metrology Ltd, Andrew said: “I think it’s been a brilliant event for Hexagon, showcasing all of the latest technologies but also showing where they are expanding and growing into; offering real manufacturing solutions.”

Discussing his relationship with Hexagon, Andrew told MTD: “We offer 3D metrology solutions for everything from production line building to body-in-white solutions and we also offer Hexagon’s full suite of equipment and software; and we have just bought the latest AT500, which will help us expand our business. We have a Hexagon Global CMM and after this, we required portable solutions to go on-site for customers. To take solutions to the customers, we bought an Absolute Arm with a scanner to gather Point Cloud data.”

Discussing the latest investment, the Leica Absolute Tracker, Andrew says: “The portable arm is restricted in the measurement volume that it has, so you only have the measurement volume for the size of the arm. With the new Leica Absolute Tracker AT500, we can take the solution onto the shop floor or even within the manufacturing environment. This gives us up to 160m in one length measurement or 320m as diameter. We can now place the tracker in the middle and measure all around the factory – this will be used in the vehicle building industry and the aerospace sector to validate jigs and fixtures. We have a big project working with a company at BMW UK for measuring the whole body-in-white projects that are being installed at the moment – the new Leica Absolute Tracker AT500 can be used on this project.”

Another station demonstrated data and information management systems. Of critical importance in the modern manufacturing environment, Hexagon displayed how its QDAS SPC suite provides reliable quality data to evaluate processes. This was complemented by the Hexagon SFx platform that integrates, analyses and transforms manufacturing data into actionable information, driving increasingly autonomous processes.

A third station, suited to the design engineering fraternity presented NCSIMUL. This ‘all-in-one’ CNC simulation software manages the complete machining process from the NC program to the machined part. It incorporates automatic G-code programming, simulation and cutting tool management.

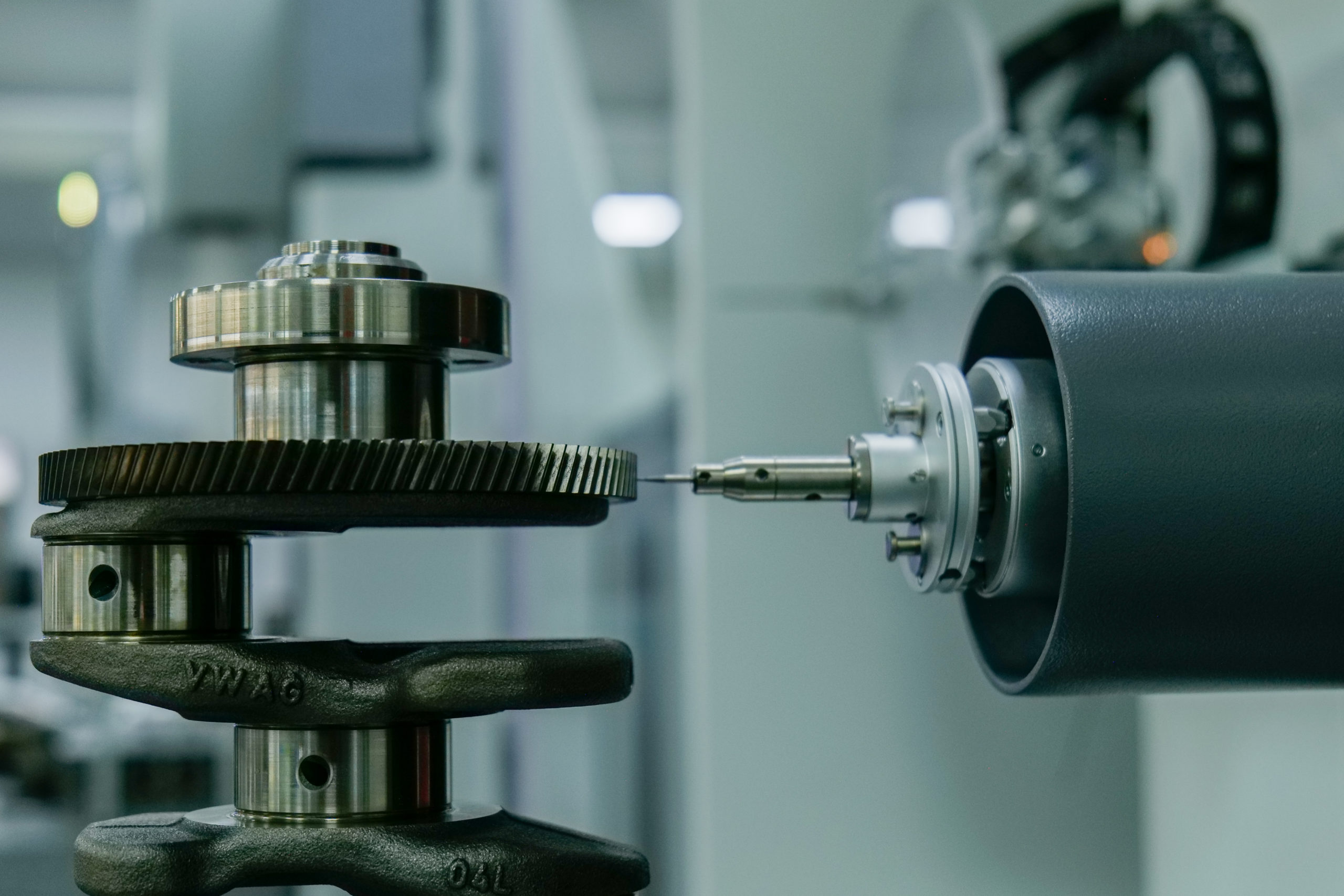

The next station introduced the stationary measuring portfolio with the Leitz SIRIO CMM that can tackle a virtually limitless number of measuring tasks with its automatic probe changer, rotary table and pallet system. At the event, the Hexagon stationary measuring technology highlighted its potential with e-mobility and powertrain component demonstrations from the automotive industry.

Discussing this, Hexagon’s Oliver Noakes alluded to the Precision Measuring Machine (PMM) saying: “This system comes into its own when we are talking to customers with really high accuracy demands. We apply this technology to customers that come to us with examples such as gearbox and transmission requirements. We can change between different contact sensors on the CMM. This varies from optical sensors to roughness sensors and laser solutions. We can use all of these in combination in one measurement run to get the best out of the machine.”

Looking at the horizontal solution that was on show, Oliver adds: “The vertical solution is configured to the absolute point of accuracy for final inspection. The Leitz Reference Sirio HP is perfect for sampling one in 10 or 20 parts to sample the process – it provides higher throughput with a very high level of accuracy.”

The Production Software station presented solutions for CNC machine shops, the sheet metal industry and also the wood/stone machining industry segment. The Hexagon software division incorporates EDGECAM, ESPRIT, RADAN, VISI, WORKNC, WORKXPLORE, SURFCAM, SMIRT, JAVELIN and many more packages that cater for different production methods. Leading the industry in everything from CAD/CAM, simulation, digital twins and smart factory solutions that encompass the entire manufacturing ecosystem from ERP and MES to planning and control systems.

The final station was all about automation and flexibility with the Absolute Scanner AS1 demonstrating its capabilities on an automotive ‘body-in-white’ example. The AS1 is the flagship 3D scanning sensor for the Absolute Tracker AT960 and Absolute Arm 7-Axis systems that uses cutting-edge blue-laser technology and advanced programming for non-contact 3D measurement. This worked in situ with TEMPO, the cost-effective automated part-loading system that increases throughput and maximises operational capacity. TEMPO enables autonomous measurement free from interruption. Whether you have overnight production requirements or staff need to switch their focus to other important tasks, TEMPO allows manufacturers to maintain output even when CMM operators are unavailable. Discussing this solution, Kieron Mcloughlin from Hexagon said: “Our new automation cell demonstrates laser tracking technology from Leica and incorporates a FANUC robot to simplify the throughput of components. We are using the system with super cat-eye reflectors to track the accurate positioning of the turntable, which essentially helps to stitch the data together. Traditionally, you would have to program the robot with the controller, but with our new software, this can be done off-line. On this system, we can measure a volume of 3m with a payload of approximately 3 tonnes – this makes it perfect for body in white applications and other instances where you need to have increased throughput.”

The event welcomed some of the most prestigious manufacturers in the UK and these key customers were quick to dig into the detail of the new technologies with application experts from Hexagon. If you would like to visit the facility and investigate the vast range of technologies available, readers can contact Hexagon for further details.