As a heavy engineering specialist, LBBC Beechwood has invested in its first CNC machine, a Kiheung U1200N milling machine from Ward Hi-Tech. The West Yorkshire manufacturer purchased the machine to replace ageing equipment. MTDCNC visited to find out more.

When asked about the requirement for new investment, General Manager Mr Andy Quayle from LBBC Beechwood says: “We manufacture pressure vessels that can be used in autoclaves and decompression chambers, we also produce heavy machined parts used in the marine industry. Before this investment, we had an old boring machine that was 60 to 70 years old, and it did not comply with the latest health and safety regulations. We needed to invest, as some of our machines are quite old – so we decided to buy a CNC machine.”

Highlighting why the Pudsey based company looked at Ward Hi-Tech, Andy Quayle continues: “I had only heard about the machines about 18 months ago after I saw an article on LinkedIn. It planted something in my mind and when it came to starting to look at investing, I thought we could give Kiheung from Ward Hi-Tech an opportunity.

Installed in 2021, the Kiheung U1200N has impressed LBBC Beechwood’s Kornel Pasztor. He says: “It was challenging to begin with because of the machine size. As we have two big doors at the front of the machine, we have really good visibility and if the cutting tool is cutting at the back of the part, we have the option to move the control panel to the back of the machine to maintain visibility. Additionally, as a universal milling machine, the head can be rotated in all angles and there is nothing that can’t be machined.”

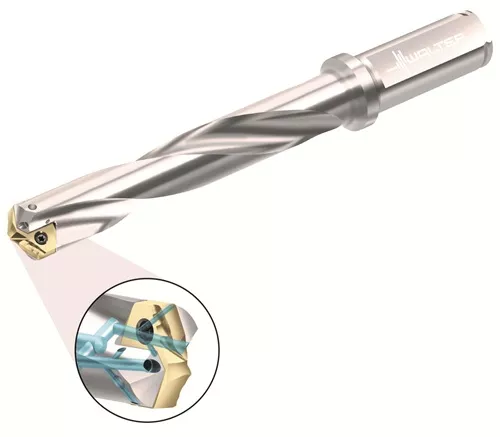

Highlighting the components being machined, Andy continues: “The machine has a 4m bed and the materials we machine can range from aluminium through to inconel, and that is the beauty of this machine – it can cut a huge range of materials. The machine has also opened up new opportunities for us. In the past, we have subcontracted out some work, but as part of the LBBC Group of companies, we have been able to bring all of that work in-house and offer a much wider range for our customers. Customers that have worked with us in the past are now recognising that we have this capability.”

Looking at the power and stability of the 2-stepped gearbox 37kW spindle machine that can accept table loads up to 10 tonnes, Kornel says: “We are regularly cutting at 2 to 3mm depth with the feed rate of 1000 to 1500mm/min. The machine is really stable, and we are cutting beyond 0.5mm per tooth on steel and only getting 10 to 15% spindle load. The machine has 24 tools in the carousel and the Heidenhain iTNC 640 CNC controller is very easy-to-use.”

Referring to Ward Hi-Tech, Andy says: “We explained that we were looking for a universal milling machine and Ward Hi-Tech put us in touch with another customer, we went to visit to see how they use their Kiheung. They showed us what it could do, and it helped to give us an informed decision.”

“It is our first CNC machine, so we needed handholding throughout the process. We had an old boring machine that we had to get out of the factory and Ward Hi-Tech were the only company that offered a complete package where they would project manage everything from sourcing a company to removing the old machine to doing the foundations and installation. They did everything and even provided a lot of training.”