At MACH, Starrag UK will be showing the company’s latest machines – the Bumotec 191neo mill-turn centre for small, complex parts. This will demonstrate how Starrag’s ‘Engineering precisely what you value’ slogan continues to help companies achieve rewards when using Starrag’s product ranges that include Berthiez, Bumotec, Dörries, Droop+Rein, Ecospeed, Heckert, Scharmann, SIP and Starrag.

Targeted at users in the medical, luxury goods and micro-mechanics industries, the new seven-axis Bumotec 191neo can accommodate bar up to 65mm diameter, and with up to 90 tools and an intuitive HMI control system, the machine will enable users to achieve a new standard in high added-value small component production in a single set-up.

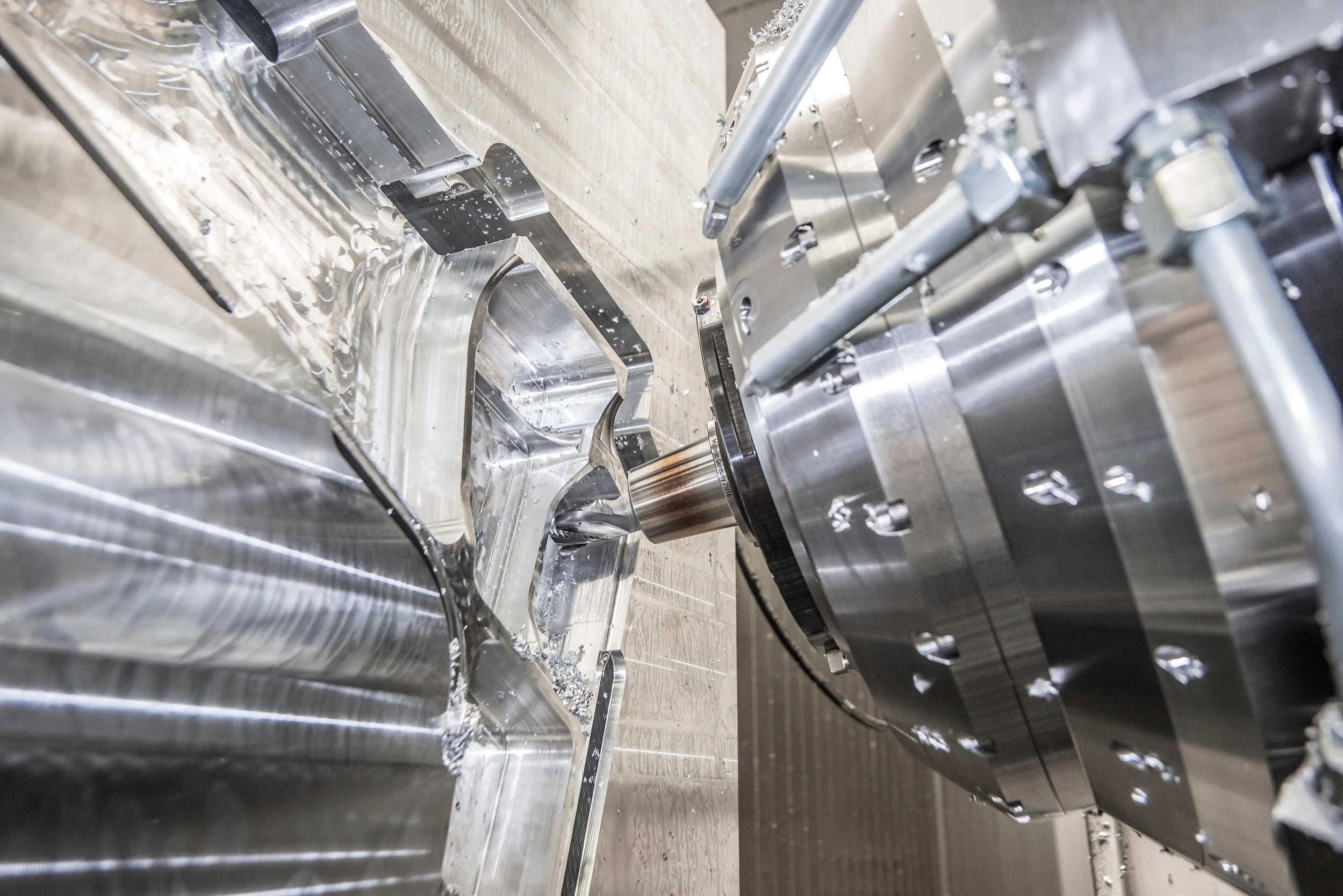

Another example of how Starrag’s success has been built on providing machining solutions for specific market demands is the affordable Heckert H65 machining centre, which was announced last year. Starrag’s new lower-cost Heckert H65 compact horizontal machining centre adds a new dimension to heavy-duty 4-axis machining with unrivalled performance for a machine of its class. Occupying just 24m2, the H65 offers machining speeds up to 30% faster than comparable models and can increase output levels by 80%.

With X, Y and Z axes of 850 by 1,020 by 1,000mm and 630 by 500mm twin pallets that can accommodate loads of 1.5 tonnes, this latest addition to Heckert’s compact H range provides traverse rates up to 80m/min and a standard spindle speed of up to 10,000rpm from its 60kW hollow shaft HSK-A100 spindle.

Aerospace, medical and luxury goods are core industries for Starrag – but so too are energy, transport and industrial components and Lee Scott, Starrag UK Director for Sales and Applications says: “Visitors to MACH from all these sectors may well be surprised, and pleased at how affordable and available many Starrag machines are.”