For the ongoing production of a part for a defence industry customer, subcontractor PRV Engineering in Pontypool has invested in a Spinner U5-630 trunnion-type, 5-axis VMC. Delivered by Whitehouse Machine Tools, the U5-630 is devoted to producing a fabricated steel hatch measuring approximately 300 by 200 by 200mm for an armoured tank in a cycle time of 5.5 hours – more than 20% faster than when the machine first arrived on the shop floor approximately 6 months ago.

The subcontractor confidently expects to reduce the single-setup cycle by a further 20 minutes as it becomes more familiar with programming the new VMC. The previous production route was to mill and bore the three-part fabrication on either of two much larger 5-axis machining centres having a 3m by 800 by 800mm work envelope, a travelling column and a swivelling B-axis spindle head. Three setups were required and the total production time was 10 hours, which meant that it was not feasible to produce one hatch per day during a single shift.

Nearly halving the cycle time, another reason for investing in a VMC dedicated to the job was a need to free up the larger capacity plant to fulfil an increasing amount of plate work. Additionally, it is more difficult and time-consuming to hold tolerance on a larger machine, as the heavier moving elements tend to cause vibration, added to which the B-axis providing one of the rotary axes is not as strong as a trunnion arrangement.

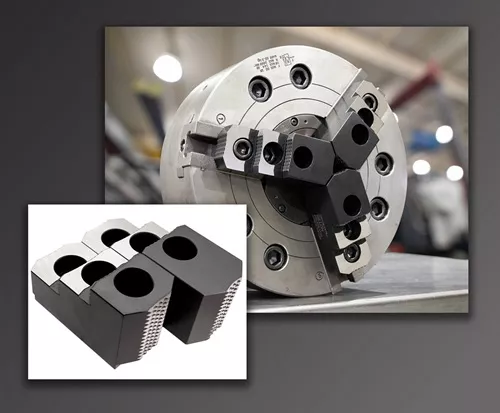

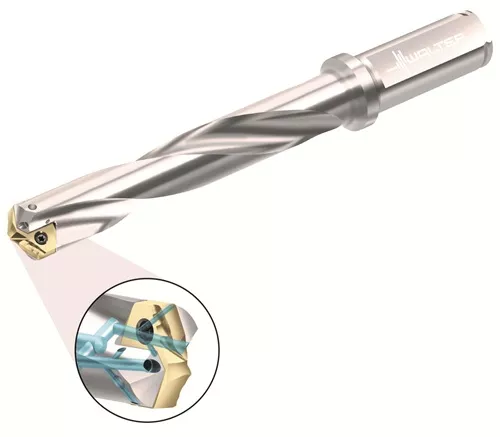

To this end, PRV Engineering’s Managing Director Simon Jones and Works Director Alun Cox set about researching the market for a 5-axis trunnion-type VMC that was appropriately sized for this defence industry contract. The Spinner option was chosen partly due to its generous 630 by 530 by 465mm working envelope in a footprint of just 2.75 by 2.53m. Ex-showroom availability from Whitehouse Machine Tools’ Kenilworth headquarters were other positive factors that influenced the decision. The high standard specification was also a bonus, as it includes a 21kW spindle motor that is ideal for machining S690QL and Hardox 400 steels, high-pressure coolant, a 32-station tool magazine, hydraulic clamping, and linear scales feeding back axis positions to a Siemens 840DSL touchscreen control with built-in ShopMill software.

The U5-630 has to be highly accurate, which pre-sales demonstrations in Kenilworth confirmed was achievable. Some tolerances are very tight on the hatch fabrication, which comprises three pre-machined and welded parts. The run-out of two holes bored from either side of the component after rotation through 180 degrees has to be to within 0.04mmTIR, while the diameter tolerance is 25µm.

Better accessibility of the cutters to the workpiece on the smaller machine is a major benefit. CNC setter-programmer at the Pontypool factory, Darek Krochmalny, explained that it is possible to use shorter and therefore more rigid tools than on the larger machine, enabling faster feeds and speeds for higher productivity.

Mr Cox concluded: “Over half of our turnover is defence industry work, with the rail, high voltage switchgear and Formula 1 sectors also regularly served. We pride ourselves on providing a full service from design-for-manufacturability through fabrication and machining to wet spray painting and powder coating.”