In the world of manufacturing, digitalisation is often celebrated for its role in improving efficiency, providing data insights, and ensuring process reliability. However, one of the most crucial, yet often overlooked, benefits of digital tools is their potential to enhance operator safety. Tobias Unosson, partner manager for digital products and services at Sandvik Coromant, sheds light on how digital tooling is helping create safer working environments for machinists.

A Shift Toward Safer Machining Environments

Machining has traditionally been a hands-on job, where operators rely heavily on experience, instincts, and manual skill. This work often involves close proximity to heavy machinery, sharp tools, and fast-moving components, all of which come with significant safety risks. While manual skills remain essential, the growing adoption of digital tools has introduced new ways to monitor and manage complex machining tasks with safety in mind.

Mr. Unosson noted, “This shift is particularly critical as the industry faces a growing skills gap. A recent Korn Ferry study predicts a global deficit of 7.9 million manufacturing workers by 2030. Ensuring safety, especially for less experienced operators, is now more urgent than ever.”

Remote Monitoring: A Game-Changer for Safety

A major advancement in digital tooling is remote monitoring, which provides real-time visibility into machine performance, allowing operators to detect potential issues early on. Traditionally, operators would need to get physically close to the workpiece to assess things like vibration, heat build-up, or tool deflection, which increased the risk of accidents.

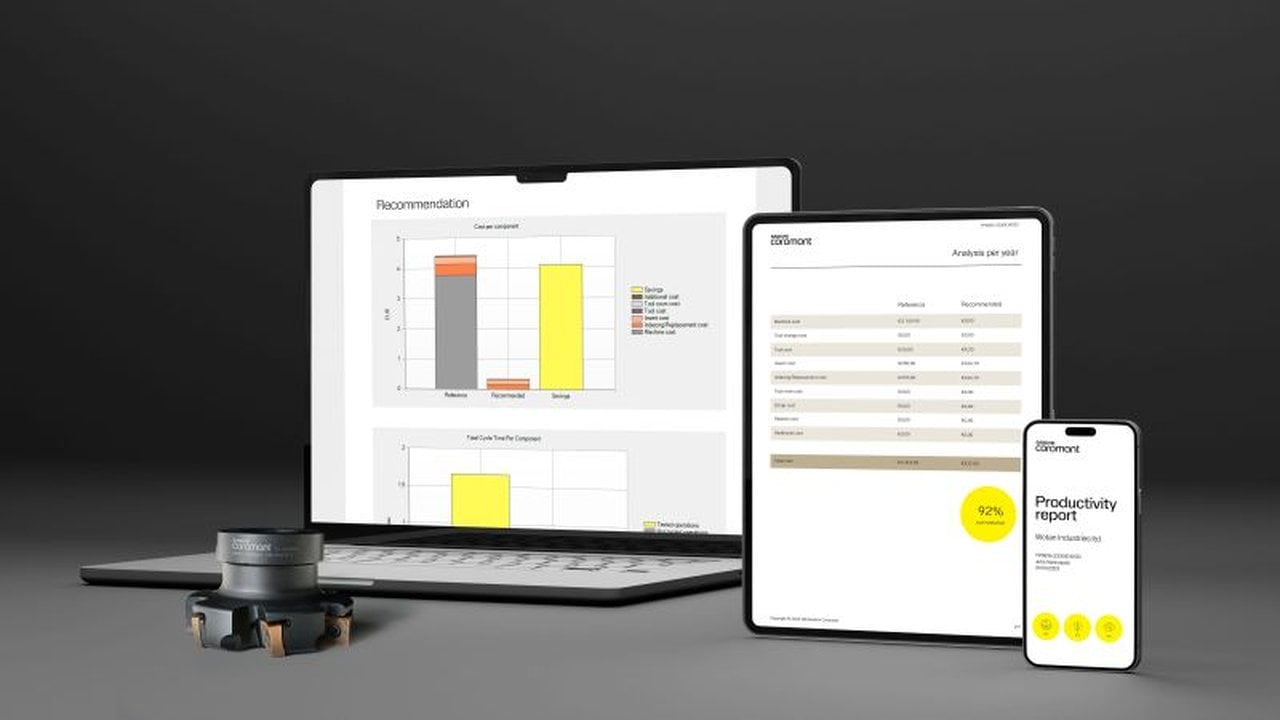

With digital tooling, many of these tasks can now be performed from a safe distance. Sensors embedded in cutting tools or tool holders track key parameters such as load, vibration, and temperature throughout the machining process. This data is transmitted to a display interface, tablet, or even directly to the CNC machine, enabling operators and engineers to monitor performance without being right next to the equipment.

Vibration Control: A Key Safety Focus

One of the most critical challenges in machining is vibration. While vibration is often seen as a factor affecting part quality and tool life, excessive or uncontrolled vibration can also jeopardise operator safety. Unstable machining conditions can lead to tool breakage, damaged workpieces, or even accidents that endanger the operator.

Traditionally, operators detect dangerous vibration through audible cues or by feeling unusual movement. However, these signals often appear too late to prevent damage or safely intervene. With digital tooling, vibration levels can now be continuously monitored. Sensors provide early warnings when conditions begin to change, allowing operators to make proactive adjustments — such as altering feed rates or spindle speeds — before instability becomes an issue.

Advanced Systems for Autonomous Mitigation

Silent Tools Plus, an advanced product from Sandvik Coromant, takes this a step further. This system, which is equipped with sensors, works in tandem with CoroPlus® Connected technology to automatically mitigate machining issues. If vibration exceeds safe thresholds, the system can automatically initiate a stop and retract process, based on the limits set by the operator. This level of automation reduces the need for manual intervention, which is particularly beneficial in high-precision or lights-out machining operations.

This is especially valuable in industries like aerospace or mould and die manufacturing, where parts often have long overhangs, thin walls, or delicate materials that make vibration more likely — and dangerous. Real-time feedback ensures that cutting stability is maintained, helping engineers keep operations safe without the need for frequent manual checks.

Long-Term Benefits for Operator Health

Beyond immediate risk reduction, digital tooling also contributes to the long-term health of operators. Continuous exposure to vibration, heat, and noise can lead to chronic conditions like hearing loss or repetitive strain injuries. By reducing the need for close-up inspections and constant manual monitoring, digital technologies help reduce these physical stressors, improving the overall health and safety of workers.

Mr. Unosson continued, “This aligns with Sandvik Coromant’s philosophy of Manufacturing Wellness — a holistic approach that not only focuses on productivity but also on creating sustainable and resilient operations. Reducing physical strain, minimising unplanned interruptions, and improving control over machining conditions all contribute to a safer and more sustainable future.”

A Smarter, Safer Future for Machining

As the manufacturing industry continues to embrace digital solutions, it’s critical that safety remains a central priority. By integrating smarter, more connected tools, manufacturers can protect their most valuable asset — their operators — while enhancing the performance and longevity of their machines.

Mr. Unosson concluded, “The adoption of digital tooling technologies offers manufacturers the opportunity to enhance safety, improve operational efficiency, and ultimately create healthier, more productive environments for all involved.”