The GROB G750T Gen 2 mill-turn machine has arrived at Sandviken, Sweden, marking a significant milestone for the flagship center. After a grueling 1,900 km journey from GROB-WERKE GmbH & Co. KG in Bavaria, Germany, the 37-ton machine was welcomed by the engineering team, ready to demonstrate its impressive capabilities.

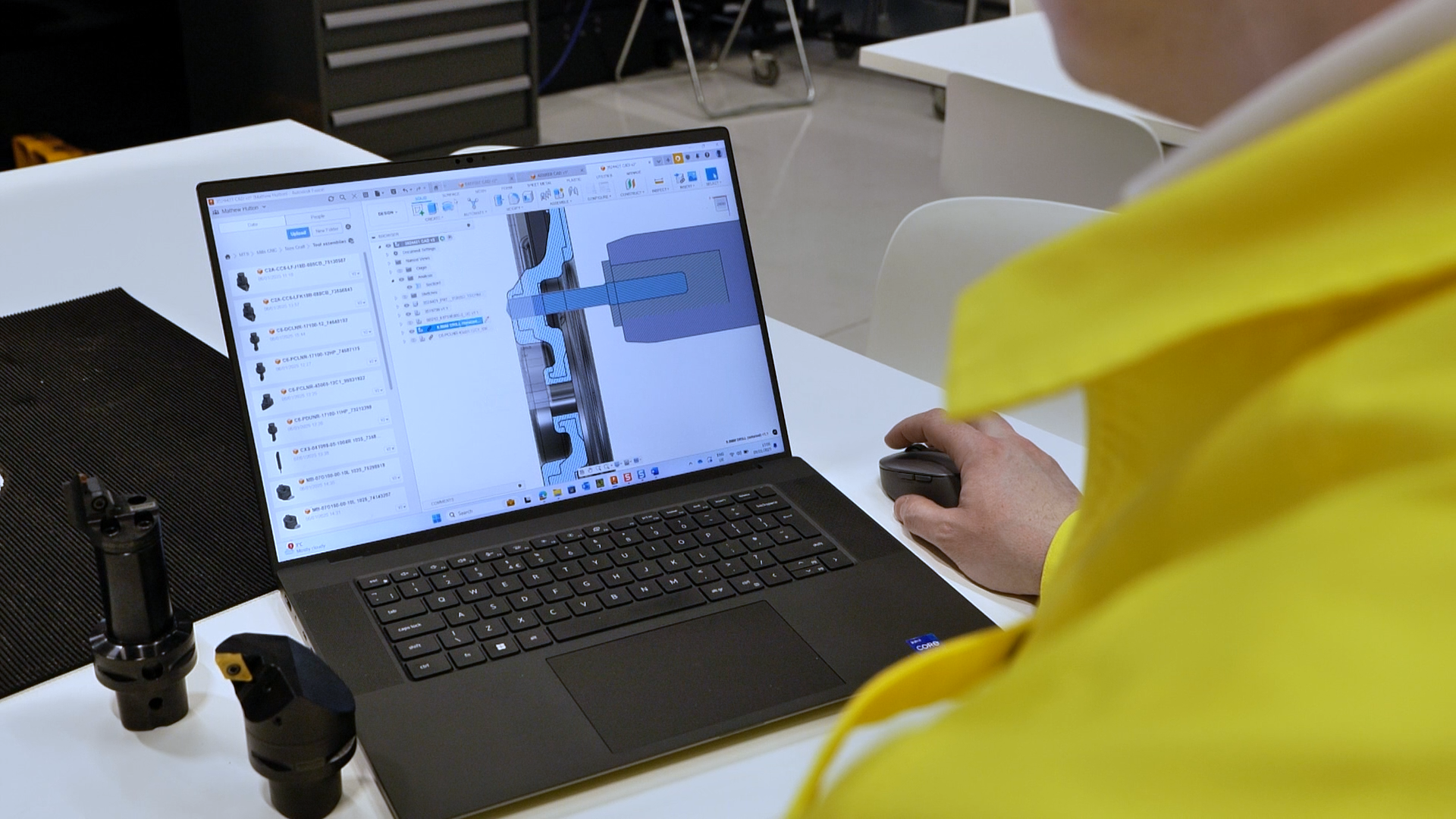

The GROB G750T Gen 2 is equipped with a 50 kW HSK 100 spindle designed for heavy-duty milling. It accommodates large workpieces with its 800 mm pallet and 1,200 mm swing diameter, offering exceptional rigidity and stability due to its considerable weight. This powerhouse is engineered for tasks including milling, turning, and power skiving, particularly suited for large gear components.

An innovative feature of the center is its ability to broadcast live footage from inside the machine. Equipped with internal cameras, the machine’s operations can be transmitted globally, allowing other centers, customers, and colleagues to witness machining processes in real-time. This digital live machining system transforms every cutting operation into a shared experience, crucial for critical tests and collaborative efforts.

The first task for the GROB G750T Gen 2 was not client-related, but rather an internal cutting test using a tool yet to be released. This live-streamed event sets the stage for future cutting-edge assignments.

GROB-WERKE GmbH & Co. KG continues to innovate within the manufacturing industry, and the addition of the G750T Gen 2 emphasizes their commitment to technological advancement and customer collaboration.

Read this post on LinkedIn