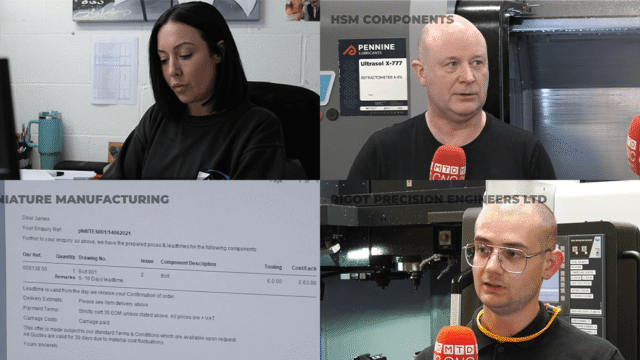

Testimonials for PSL Datatrack

Hear what clients have to say about PSL and their software.

In the third and final in a series of Q&A sessions with PSL Datatrack’s Managing Director, Geoff Gartland, we discuss how to ensure you choose the right production control software system for your subcontract precision engineering business.

As discussed in the first article, production control software helps to manufacture quality parts that are right first time, sold at the right price and delivered on time.

The second article covers many of the benefits resulting from investment in and implementation of production control software. So how do you choose the right package?

What do you need the system to do? This all depends on the size and nature of your business.

Many subcontract precision engineering companies come to PSL Datatrack looking to streamline the entire production process from quotation to invoice and help to achieve or maintain ISO/other accreditations. Others want to improve on one or more major areas such as quoting, scheduling and job costing. As PSL Datatrack is modular, it can be tailored to the exact requirements of the customer in question.

Is it simple and easy to use? This is just as important as the functionality of the software – it is no good having a powerful system if it is overcomplicated and hard to learn.

With PSL Datatrack, all screens are similar in appearance and layout to help users pick up the system easily. Data flows throughout, preventing manual data re-entry wherever possible. Users can also set a ‘Roadmap’ as their home screen to help familiarise themselves with the links between all modules.

What do your customers’ customers need as a result? End customers ultimately need the right components on time for their own parts and products.

PSL Datatrack incorporates a delivery performance report which lists deliveries made against their associated works order due date and categorises them as early, on time, late within 7 days and late over 7 days. Many PSL Datatrack users also run status boards to highlight customer deliveries due out on a particular day.

How about traceability? This is another key customer requirement and an automatic, integral PSL Datatrack feature.

After implementation of a PSL Datatrack system, many companies have thrived from its traceability features including the generation of certificates which are vital to so many industries such as aerospace and defence.

The system can ensure complete manufacturing traceability by providing and recalling full documentation of every job for every customer instantly. PSL Datatrack has a traceability report in its Works Orders module which shows a concise summary for every job of related records from all other PSL Datatrack modules.

How much does production control software cost? Is it in your budget? It is always good to have a budget in mind when considering new software.

As mentioned previously, PSL Datatrack is modular and so the cost is calculated depending on the features and options selected at the start. Additional modules can then be purchased as and when they are required in the future, so you do not need to commit to paying for the entire package at the outset.

Which modules do you need? Again, this all depends on the size and requirements of your company.

PSL Datatrack will always demonstrate the system to prospective customers to show them all areas of the system and how they tie together. The customer can then go away and think about which modules they need from the beginning. The modules/features available are:

The complete system has in excess of 1500 configuration options, many of which have a choice of settings as opposed to a straight yes/no, which can be individually set to the needs of the customer.

Will it grow alongside your business and future requirements? For any business seeking growth and improvement, this is a key consideration – it’s no good investing in a system that will be outgrown in a year or two.

With PSL Datatrack, users can start with a compact package of modules which can be added to as their business or requirements change. Existing modules and the data within them will instantly link with any new modules added at a later stage.

Datatrack is constantly being developed, with a full upgrade released every 1-2 years based on our own developer ideas and those submitted to our customer Wishlist. We encourage new ideas from users and bespoke development can be commissioned where necessary.

Does it need to be designed and supported in the UK? This depends on the nature of your work but the importance cannot be overlooked.

Having provided production control software for over 30 years, PSL Datatrack has a wealth of experience in the British Manufacturing industry and provides technical support to our customers, 09:00 – 17:00 Monday to Friday, from our offices in Bracknell, Berkshire. Wishlist ideas submitted by customers are often topical and more often than not benefit the vast majority of the user base.

Can existing, useful data be imported? Some software packages require a fresh start, whereas some can import historic data to use as a starting point for the new system.

PSL Datatrack has many years of experience and skill in this area to help customers get their system up and running as quickly as is practical, using data formatted in CSV files which can come from one or both of existing systems and accounts systems.

How will the system be implemented? Precision engineers are always busy and so implementing a new piece of software may not seem the easiest thing to do.

However, PSL Datatrack has a clear and concise Implementation Plan to follow with the knowledge that no two implementations, just like no two businesses, are ever the same. We will always remote in and install the system for our customers on whichever PCs they wish to use it on, and will then provide training at a convenient time for the users involved. We want to help, not hinder!

To summarise? There are many factors to take into account when considering which production control software system is right for you and your business.

PSL prides itself on the bespoke and tailored nature of Datatrack and the many positive testimonials from our customers, who are happy to appear on camera and talk about their use of our system.

If you are interested in finding out more about us then please do not hesitate to contact us via any of the following methods to arrange a free, no obligation demonstration today. It could be one of the best choices you ever make for your business!

Be first to see all the updates from MTDCNC

Our newsletters frequency varies dependant on content

All the latest deals from the industry feature on our newsletters