At the EMO exhibition in Hannover, OPEN MIND Technologies presented a ground-breaking addition to the hyperMILL® CAD/CAM suite. As one of the world’s leading CAD/CAM solutions, OPEN MIND presented its hyperMILL® ADDITIVE Manufacturing suite for satisfying the requirements of industrial 3D printing processes. As a universal software solution, hyperMILL® – together with this option will provide efficient hybrid processing with simultaneous additive and subtractive processing on one single machine platform.

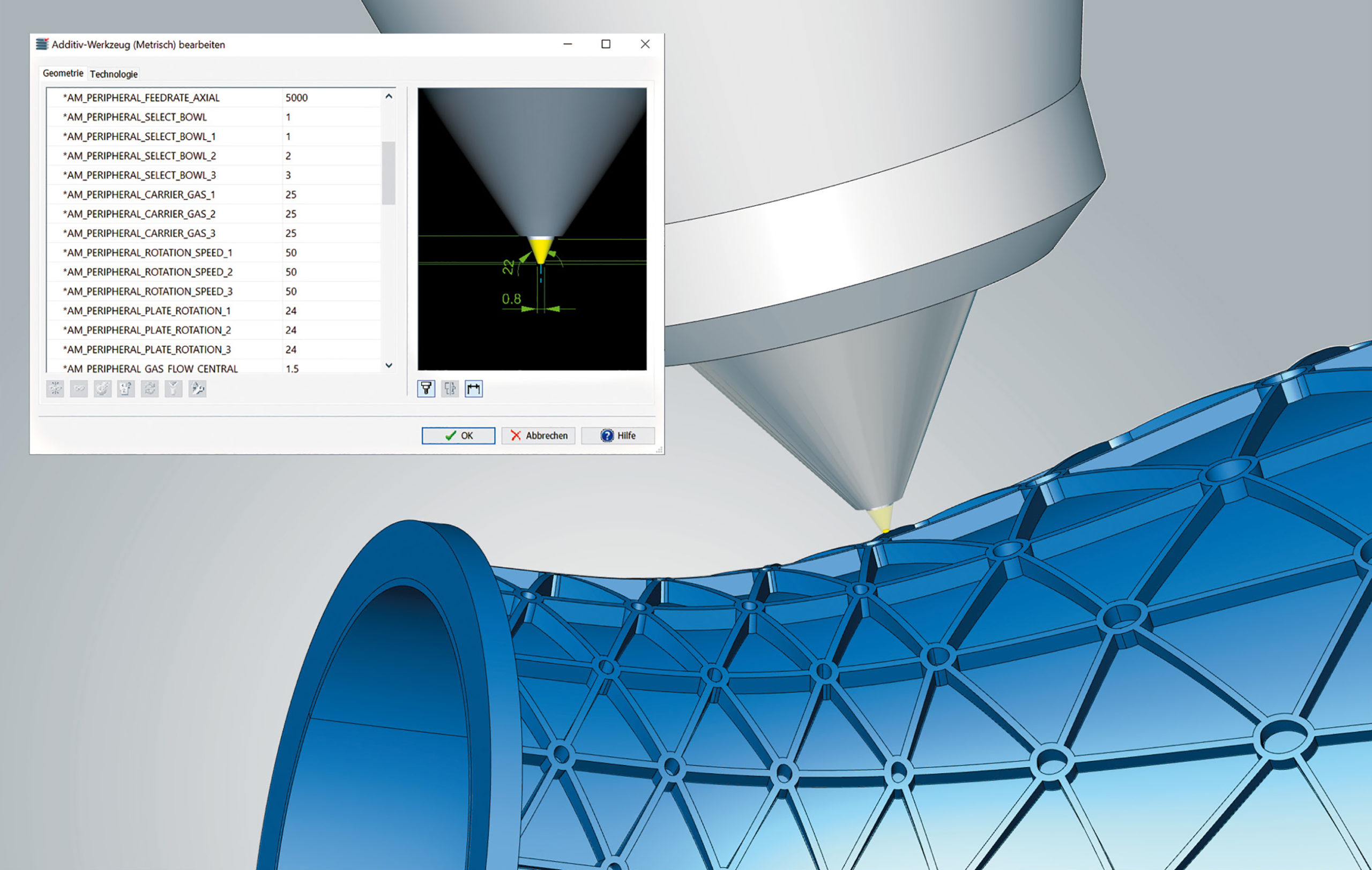

hyperMILL® ADDITIVE Manufacturing opens up an array of flexible options for Directed Energy Deposition processes (DED) and Wire Arc Additive Manufacturing (WAAM) in terms of highly complex 5-axis simultaneous processing. Both laser-based powder nozzle machining heads and wire arc additive manufacturing can be controlled using the software from OPEN MIND for selective material deposition, as well as conveniently programmed and automatically simulated for collision avoidance.

Reworking and hybrid manufacturing in one process

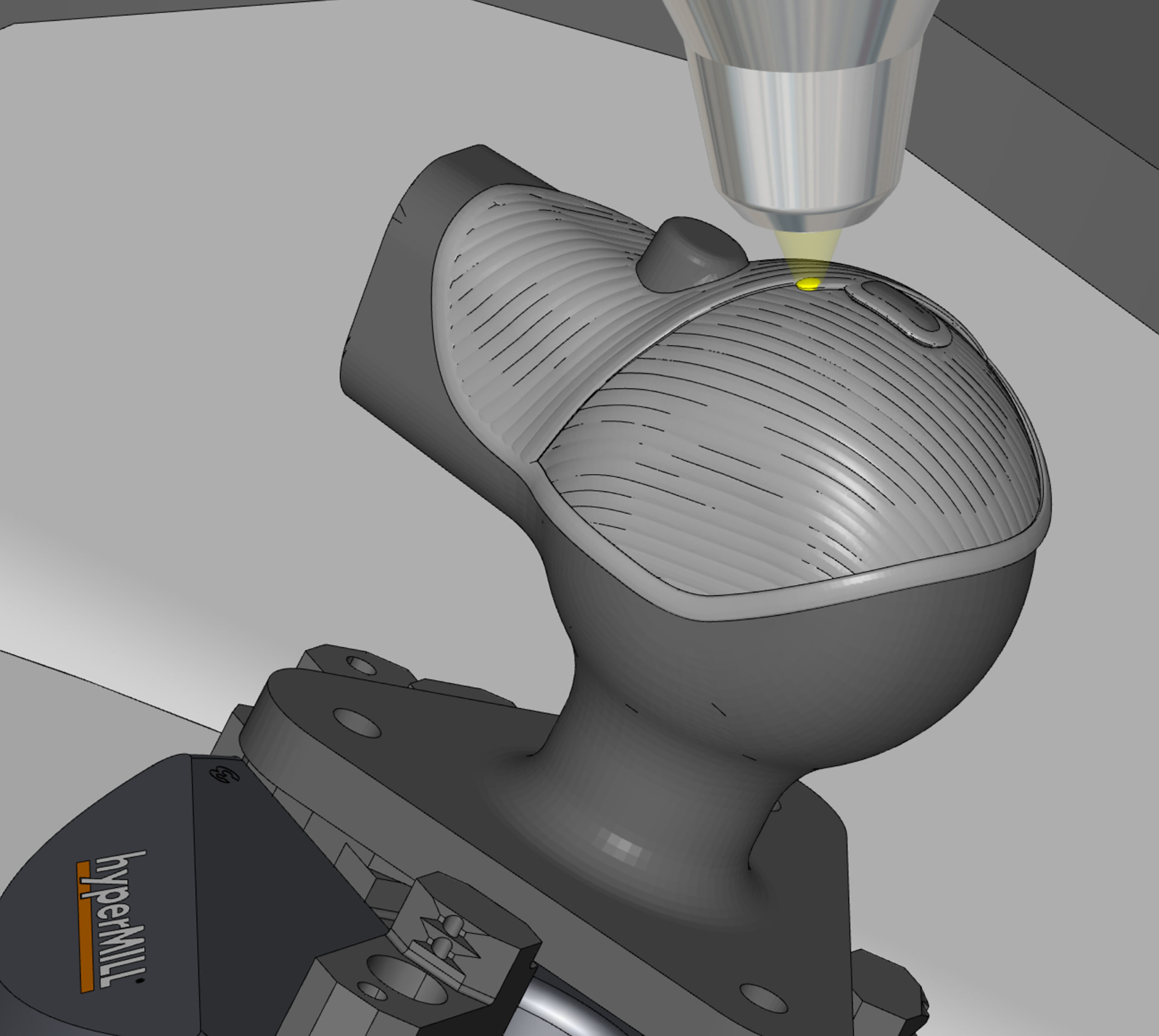

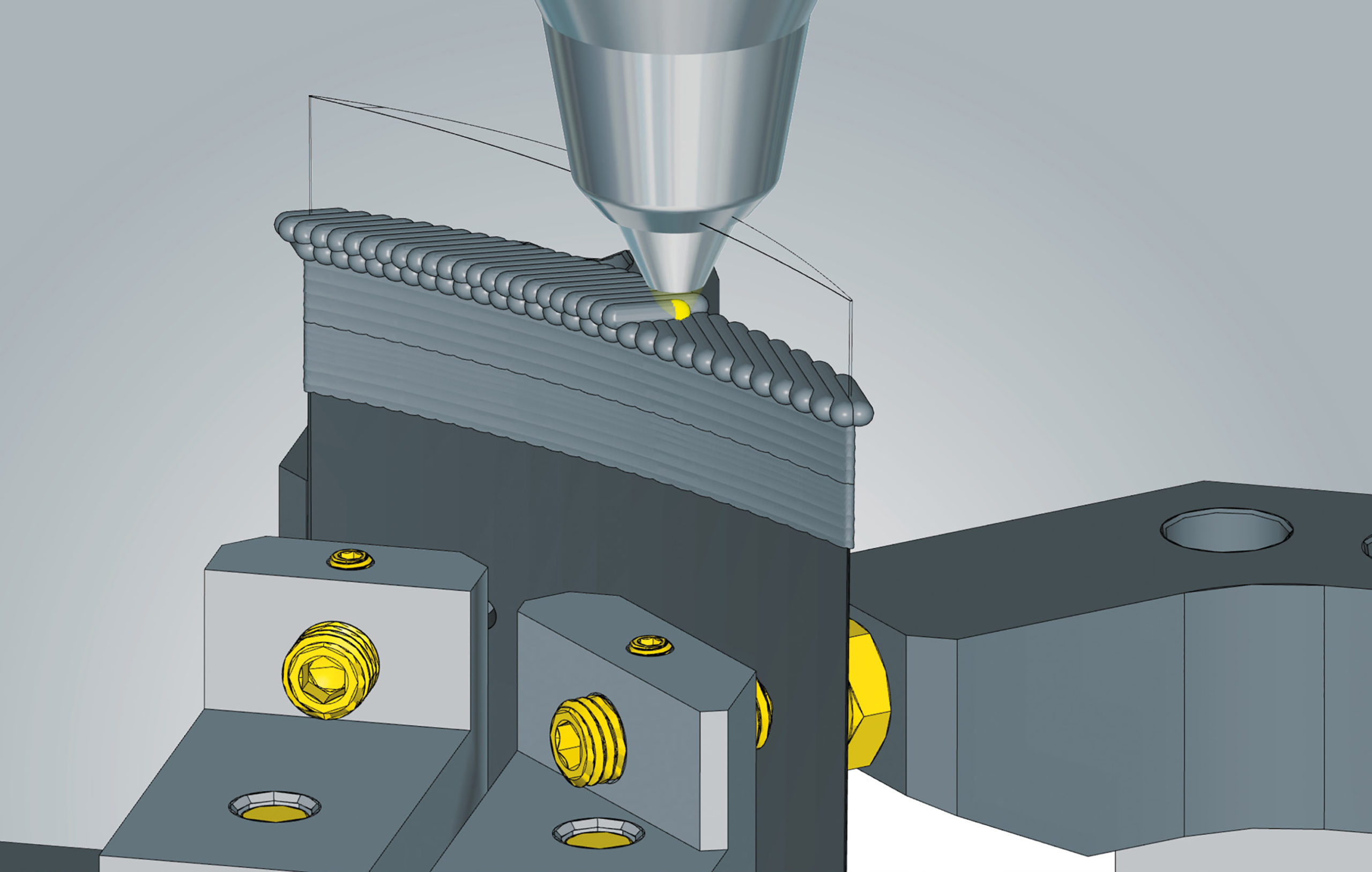

hyperMILL® now allows the potential of additive manufacturing to be truly exploited using Powder Bed Fusion (PBF). If 3D-printed parts do not offer the desired precision or support structures have to be removed, the parts can be machined afterwards by means of 5-axis machining. Even hard-to-reach areas can be machined in a secure manner using hyperMILL®. As an integral part of the process chain, the CAD/CAM system from OPEN MIND supports reworking of this nature. The printed components are analysed, milled to size and examined.

As the industry leading CAM specialist, OPEN MIND is indeed driving forward implementation of integrated process chains. Additive and subtractive manufacturing are combined in one single machine tool for hybrid manufacturing. hyperMILL® now enables users to perfectly program the cladding and the milling together. True-to-detail application and removal simulation as well as stock tracking between the individual machining steps guarantee the greatest possible process reliability.

Efficiency and process reliability

“Our early work on industrial additive manufacturing processes is now bearing fruit. hyperMILL® ADDITIVE Manufacturing allows us to boost the efficiency, precision and process reliability of additive and hybrid manufacturing. We want to integrate these new procedures in established process chains, thereby increasing their efficiency and opening up potential applications,” says Volker Nesenhöner, CEO at OPEN MIND Technologies AG. “We are able to contribute to many innovative solutions and significantly expand the range of applications for these new procedures.”

Important applications will include repairing damaged components, such as in mold-making and toolmaking or repairing turbine blades in the aerospace industry. This also opens up totally new options for combining different materials, such as when high-quality material layers have to be applied to carrier materials.