Hioki Unveils Innovative Powder Impedance Measurement System to Accelerate EV Battery R&D!

By Ashutosh Arora

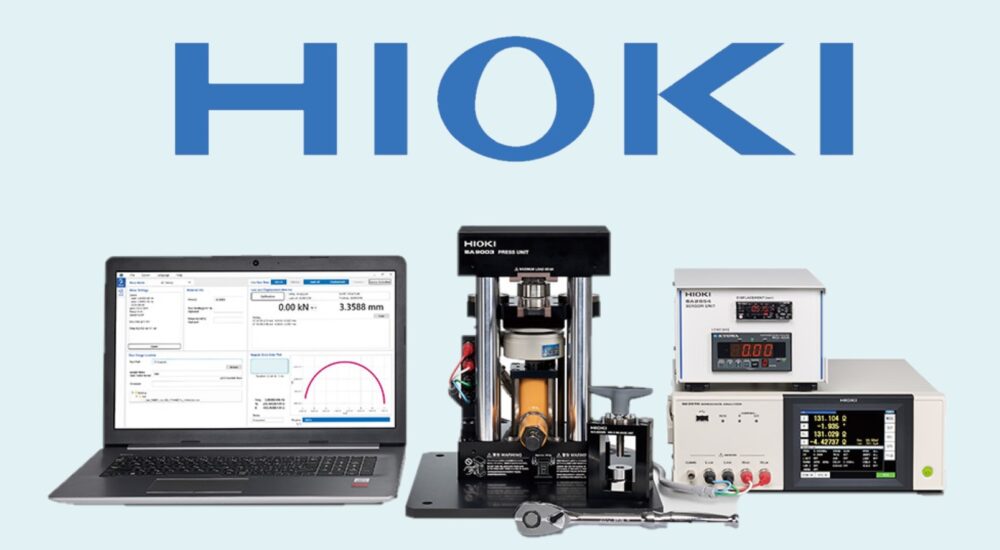

Hioki E.E. Corporation has introduced its advanced Powder Impedance Measurement System, tailored for the electric vehicle (EV) solid-state battery research and development sector. This cutting-edge system enables the simultaneous measurement of critical parameters essential for assessing solid-state battery materials, thereby enhancing both safety and cost-efficiency in the evaluation process. Equipped with a compact press unit, multiple measurement modules, and specialized software, the system operates entirely within a glove box to maintain a controlled environment, reduce contamination risks, and improve work safety.

Solid-state battery research, integral to advancing sustainable energy solutions, faces material challenges requiring precise handling, particularly with sulfide and halide materials that are sensitive to moisture. Hioki’s all-in-one system addresses these needs by offering a glove box-compatible press unit capable of pressing up to 764 MPa, allowing for continuous impedance, thickness, and pressure measurements. By conducting evaluations entirely within the glove box, the system reduces material usage, eliminates the need for multiple samples, and increases experimental efficiency, driving advancements in solid electrolyte technology and safe, high-performance BEVs.

Hioki’s latest technology optimizes the research environment for EV battery development, promoting cleaner and more sustainable energy solutions. This breakthrough is set to be a valuable asset in the push towards renewable energy and the future of electric vehicles.