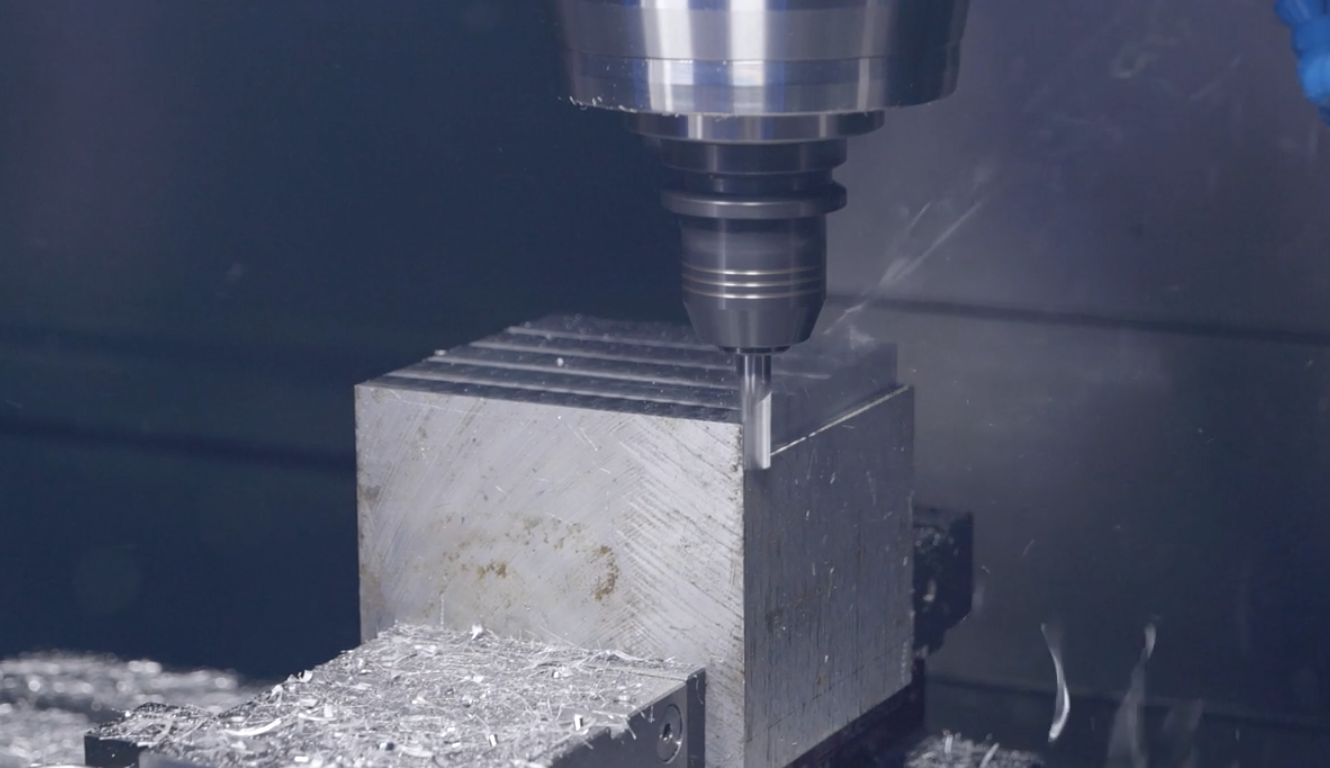

For more than 70 years, Nomura has designed and crafted precise, reliable swiss-style turning machines and offering U.K. manufactures machines that exceed their expectations! Their high precision, durability and innovation are perfect for large volume production of aerospace, medical and automotive parts.

Nomura also manufacture tapping machining centres which are based on their latest design and technology and have recently released the DST 40DS and DST 42DS. These are compact drill and tapping centres, capable of machining highly accurate parts at high speeds and maximising productivity. The standard spindle speed is up to 15,000rpm, with an option of 24,000 rpm if required. These machines are perfect for high-volume parts like medical components and electric car batteries.

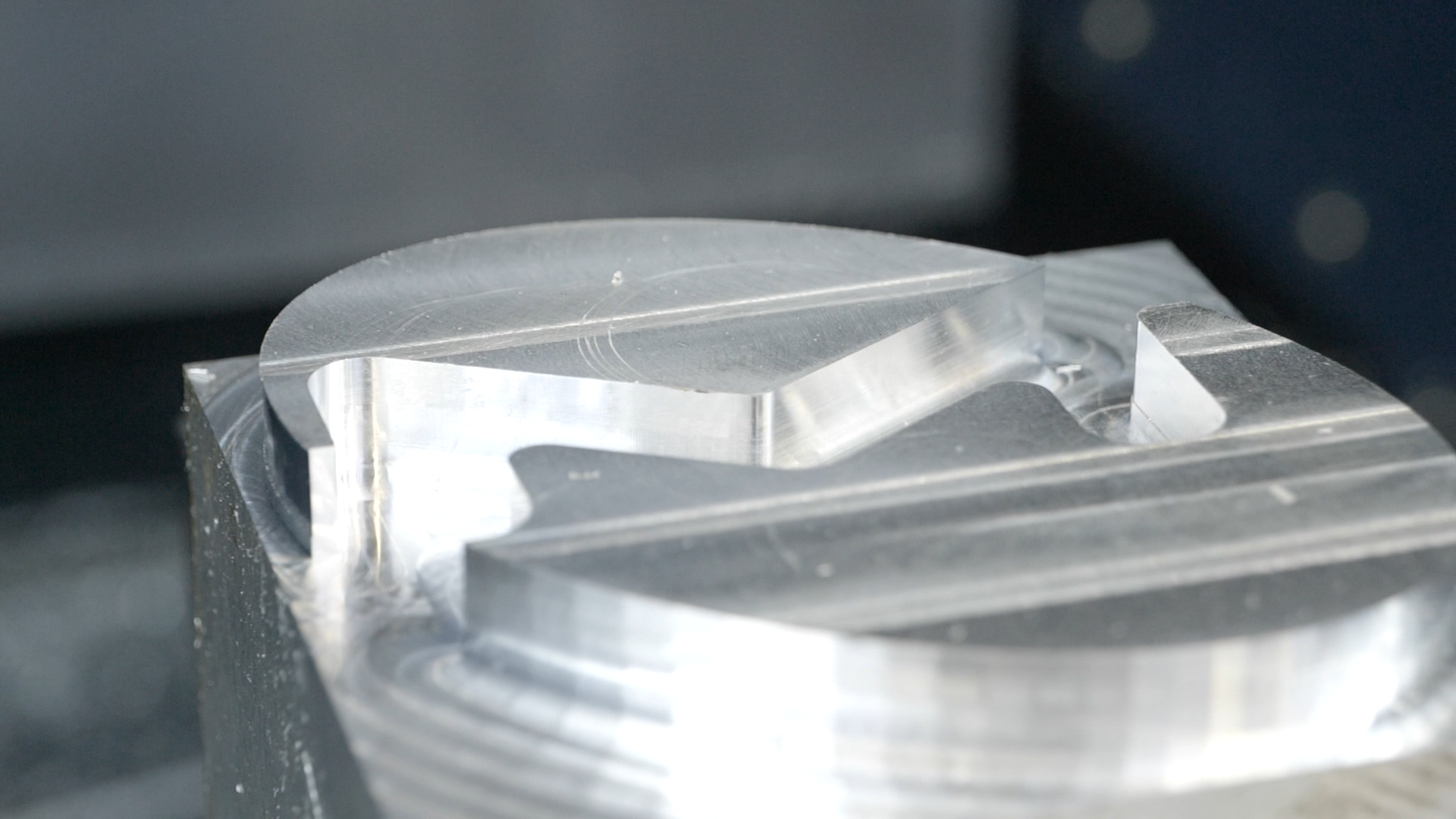

Nomura employs traditional hand scraping techniques that produce an ultra-precise surface with sub-micron flatness of less than 0.0001 mm. The skilled process, which is called Kisage and uses a variety of hand tools, can take up to ten years of practice to perfect and achieve, sometimes taking a day to achieve the perfect desired flatness. The resulting finish is superior to grinding as it improves lubricating oil flow and reduces wear.

For more information on the range of Nomura machines visit www.leadercnc.co.uk/Nomura or alternatively follow us on our social media channels.