One of the UK’s leading industrial filtration specialists is heading to MACH 2020 with a simple message for manufacturers… create ‘clean air’ workshops and production environments to protect your staff and ensure compliance with Health and Safety Executive (HSE) regulations at the same time.

Filtermist Systems, which opened a brand-new purpose-built distribution centre in Telford last year, will be exhibiting for the first time as the new enlarged group and is promising to deliver a complete solution in one place.

Latest products from Kerstar, Ecogate, FastClip and Dustcheck will be taking centre stage on its stand (6-420), whilst a new Augmented Reality app will give visitors a closer look at the technology and technical experts will be available to talk about the best way of ensuring workplaces are free from contaminants, including oil mist, dust, smoke, fume and VOCs.

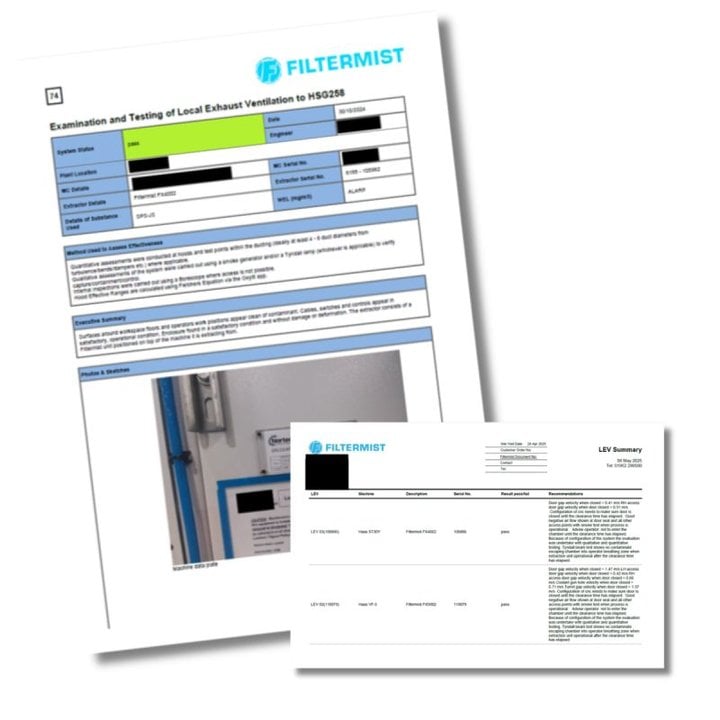

Given that the HSE’s current inspection programme aims to target 800 fabricating companies in 2020, Filtermist is confident that having access to expert advice throughout the week will be welcomed by MACH visitors.

“New guidance has been released about welding fumes (including mild steel) being classed as carcinogens and this, along with minimising exposure to metalworking fluids, needs to be addressed by manufacturers spanning automotive and aerospace to high value engineering and renewables,” explained Andy Hives, Director of Group UK Sales for Filtermist.

“As part of the recently introduced enforcement changes, the HSE is stepping up its number of inspections and firms will need to ensure they’ve taken the necessary measures to be compliant or face costly fines.

“Products, including Filtermist’s newly introduced F Monitor 2, are designed to make it easy for machine operators to spot if their Filtermist oil mist filter needs servicing, helping manufacturers ensure they’re continually providing a clean working environment for employees.”

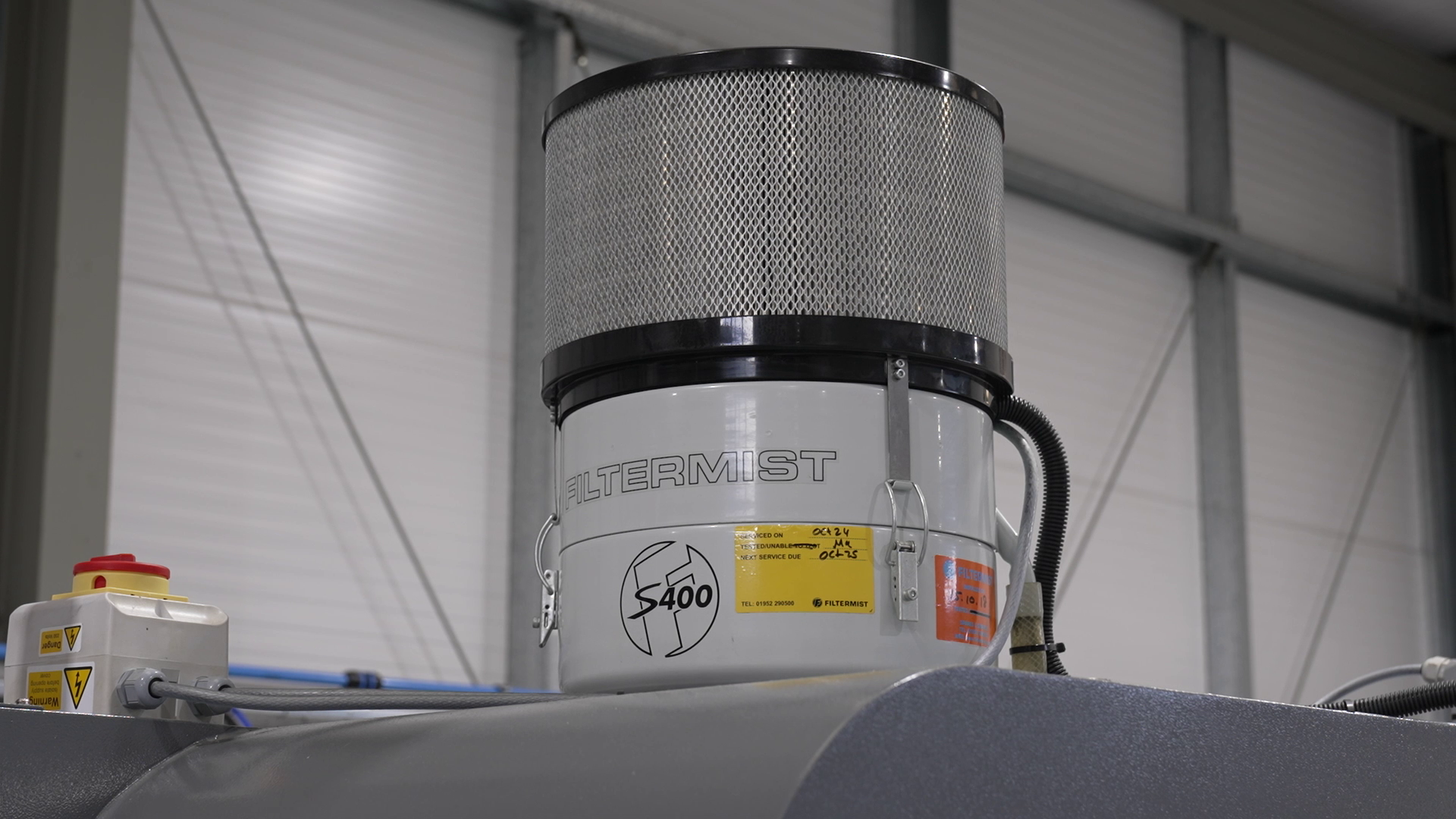

Historically, Filtermist is known for manufacturing a range of compact centrifugal oil mist filters, but as the UK distributor for sister companies Absolent AB and Bristol T&G International GmbH, it also offers static filter media filtration systems and electrostatic filters.

Andy went on to add: “We have provided effective oil mist extraction solution for customers’ specific requirements for more than 50 years.

“Our recent acquisitions have now given industry a single-source solution to tap into for a much wider range of contaminants. Whether that is initial advice and LEV testing, right through to supplying the latest oil mist filtration systems and state-of-the-art wet collectors. Our Systems business can also project manage the entire installation.

“Creating a ‘clear air’ workshop has so many more benefits than just meeting legislation. It has been proven to improve morale and increase productivity, whilst also reducing staff sickness. MACH 2020 will offer delegates an insight into the latest technology we can deliver.”

New products that will be showcased include:

Kerstar Swarf Vacuum Cleaners

The KSV 45/2 C is a portable industrial unit designed to pick up metal chippings and swarf (excluding spirals) from milling machines and lathes for example, where most of the liquid (suds) have drained into a sump.

The motor unit is protected from the ingress of metal by a liquid resistant filter assembly, whilst the filter assembly is protected from metal chippings by the cyclonic separator.

The cyclonic separator directs the majority of the metal chippings downwards into the swarf basket in the canister, which holds the metal chippings. When the basket is lifted out of the canister any liquid drains out through the perforations in the basket and back into the canister, making it easy to dispose of.

FastClip

High performance clip-fit extraction ductwork and accessories, manufactured in Filtermist Systems’ Yorkshire manufacturing facility, are commonly used for transporting dust and fume.

Ecogate

Ecogate technology can reduce the costs of running extraction systems by as much as 75%. Sensors monitor when machines are in use and automatic dampers direct airflow where it is needed – minimising unnecessary extraction and significantly reducing energy consumption.

Dustcheck Wet Collectors

Dustcheck’s Wet Dust Collectors (also known as wet scrubbers) use water and air pressure to ‘scrub’ dust from the air.

Wet Dust Collectors send the dust through a water spray then, using gravity, dust is separated from the water and the dust can be removed. Dustcheck’s range can be used on metal finishing applications, such as grinding, finishing and fettling, where the materials used could include aluminium, titanium and magnesium for instance, which may present a fire or explosion risk.

A dedicated wet collector specialist will be on the stand from Monday to Thursday.

Andy concluded: “MACH 2020 is one of our biggest shows and we’re delighted to be presenting the full Filtermist range to an industry that needs to take more strides towards delivering cleaner factories and production facilities.

“Our turnkey solution gives customers a simple way of accessing the latest technology and the unrivalled expertise of a 250-strong workforce. That’s a pretty powerful combination and this is reflected in continuing demand for our offer.”

For further information, please visit www.filtermist.co.uk or follow @filtermistuk on twitter