Toolholders were designed for mounting cutting tools reliably. They also facilitate the torque transmission from a machine spindle to a rotating tool. It has been a long time since we have encountered significant changes in toolholding, which may suggest we are behind in innovation. Indeed, well-established tool clamping principles, the need for wide interchangeability and unification and standardised designs of machine tool adaptations have resulted in well-defined standards, which specify detailed toolholder parameters. But this doesn’t mean that new innovations and developments are over.

Time puts new demands on machining, which has transformed into new requirements for machine tools, and consequently, cutting tools and toolholders – both elements of a chain that enables the recognition of machine tool capabilities possible when machining a part or a surface. The toolholder relates to the most ‘conservative’ link of the chain and has undergone fewer revolutionary changes for the noted reasons.

The Industry 4.0 philosophy has had a serious impact on toolholding. Smart manufacturing and the demands of tomorrow’s manufacturing is requiring intelligent toolholders to exchange data via Internet of Things (IoT) platforms. This will lead to new information capabilities of toolholders by adding more and more electronic units. Even today, built-in chips provide various data regarding a toolholder that communicates with machine tools, industrial robots, storage devices and more.

Adding a new data function is no doubt an extremely important direction in the evolution of toolholding development. However, it does not negate the need to continually improve mechanical design, which may look a little bit prosy when compared to the enthusiastic data intelligence of smart tooling. However, it should be noted that a traditional development that relates to the advancement of toolholders as mechanical systems, is very far from coming to an end.

Recent improvements in toolholder designs are distinctly seen in the following areas:

1. Heat-shrink chucks

High-speed machining (HSM) methods have brought tool balancing requirements to new heights. In HSM, the dynamic characteristics of a tool cannot be separated from a toolholder, and a particular focus must be given to the assembly on the tool and the toolholder. Hence, minimising the unbalance of such an assembly is one of the challenges tool developers face. They have tried to guarantee the required balance parameters at the design stage before production. This engineered balance design cannot replace ‘physical’ balancing of an assembly, but it substantially diminishes the mass unbalance of a future product and makes ‘physical’ balancing much easier. Axisymmetric heat-shrink chucks optimally meet the requirements of a balanced toolholder for HSM already in the design stage. This explains why the advance of heat-shrink chucks is of priority.

2. Coolant supply

A pinpointed coolant supply through a tool body, such as when coolant flow is directed to a cutting zone significantly improves machining performance. The industry requires more advanced toolholders with internal supply options, especially for machining with high pressure coolant (HPC).

3. Modular quick-change tooling

A modular design principle considerably simplifies finding the optimal configuration of a tool assembly and diminishes requests for special tools.

4. Long-reach applications

Long-reach machining applications inherently require the long overhang of a tool assembly, which leads to poor stability that increases vibration. New solutions with improved assembly strength are just one of the trends of toolholder development in this area.

5. Polygonal taper connection

The ISO-standardised polygonal taper adaptation has proven itself and become common in multitasking machines and turning centres.

These are only a few of the high-profile directions for developing toolholders. The others are focused on high-torque transmission to prevent tool pull-out because of the high axial cutting forces. Other innovations evolve around increasing accuracy and creating more ergonomic solutions. Therefore, the conclusion of a seemingly stagnation in the mechanical design of toolholders is far from correct.

By use of example, let’s consider the newest toolholding releases from ISCAR over the past few years.

Recently, ISCAR expanded its family of heat-shrink holders by adding new chucks with C8 polygon taper shank. The chucks offer several bore sizes from 6 to 32mm. The introduced products feature coolant channels along the chuck bore to provide effective coolant supply to the cutting edge of a clamped tool.

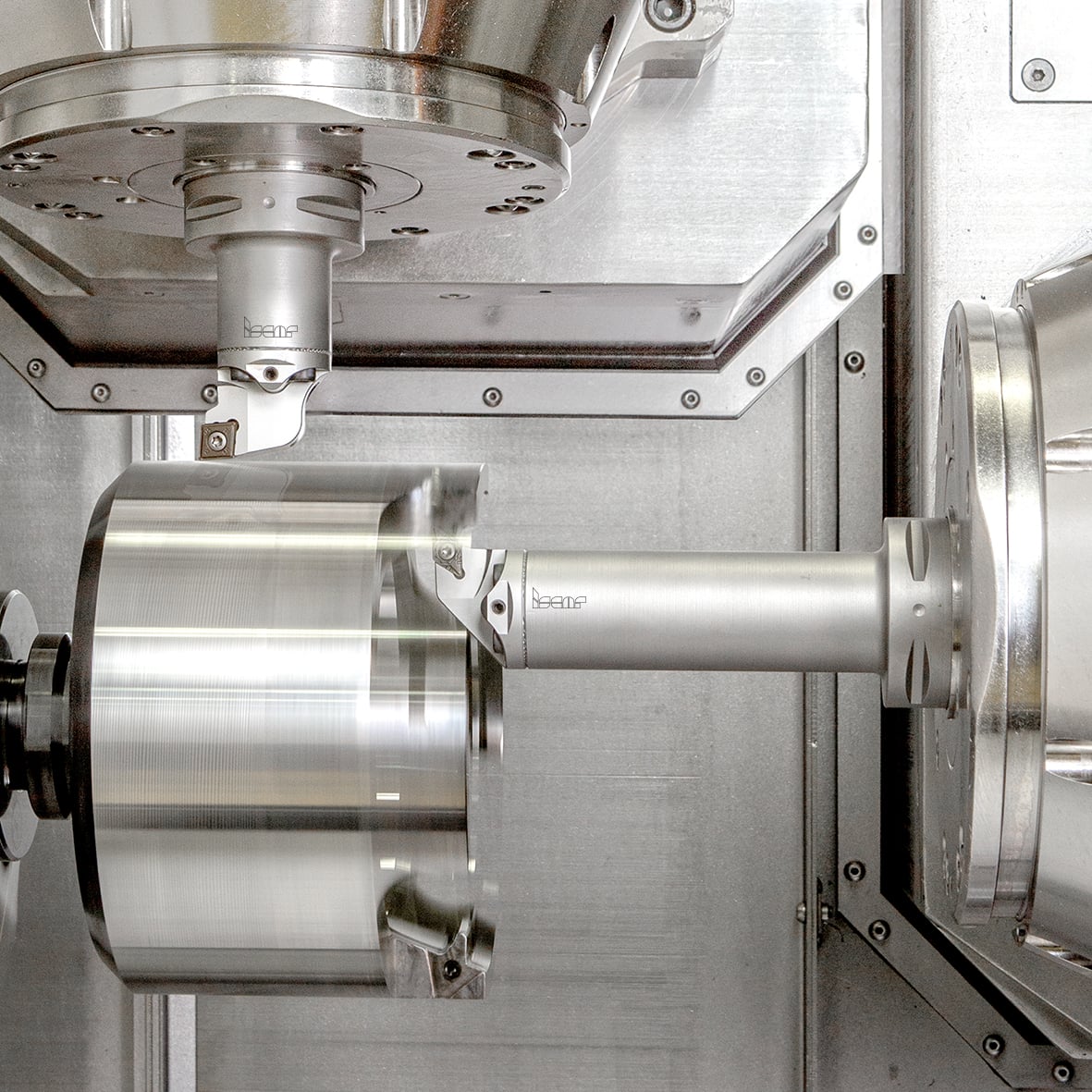

Due to increasing popularity of the polygon taper adaptation, ISCAR has developed a new tool family for external and internal turning and threading applications. A modular concept enables various tool assemblies using a wide range of cutting heads with indexable inserts. These are mounted on toolholders with polygon taper shanks with a serration-face connection.

What else can be seen as new in ER spring collets? Tool manufacturers have developed a rich variety of precise collets that offer coolant supply capability. For example, ISCAR’s new updated ER rubber sealed collets with an extremely narrow collapse range ensure better clamping force, maintain high runout accuracy of 0.005mm and facilitate four cooling jets.

ISCAR’s integral collets, tools with a tapered shank for direct mounting in ER chucks are accurate and rigid tools. These are considered as toolholders in their own right. The front of the collet has its own adaptation for mounting cutting heads with indexable inserts or they are fully made from cemented carbides.

Hydraulic chucks ensure high gripping torque that is vital for heavy-duty machining. During recent years, ISCAR extended its product range of hydraulic chucks, they are now available with BT-MAS, DIN 69871 and HSK shanks. In addition to a high-torque transmission and fast tool-change capabilities, the hydraulic chucks are characterised by excellent vibration damping properties and high accuracy.

ISCAR developed a system of quick-change assembled tools specifically for turning aluminium wheels. A tool assembly comprises of a cutting head and a holder. The head is mounted on the holder by use of a dovetail connection. The dovetail mechanism assures full-face contact between the holder and the head with very high clamping forces and this enables it to resist tough cutting conditions when turning wheels. The holders are produced with VDI40, VDI50 or round shanks.

We can see that progress in toolholding is far from exhausting the resources of advanced design. Although high-quality toolholders have reached the right level of performance to meet the needs of today’s manufacturing challenges, the smart factory of tomorrow demands an even higher level. Intelligent design in combination with progressive technology, continues to play a key role in toolholding improvement.