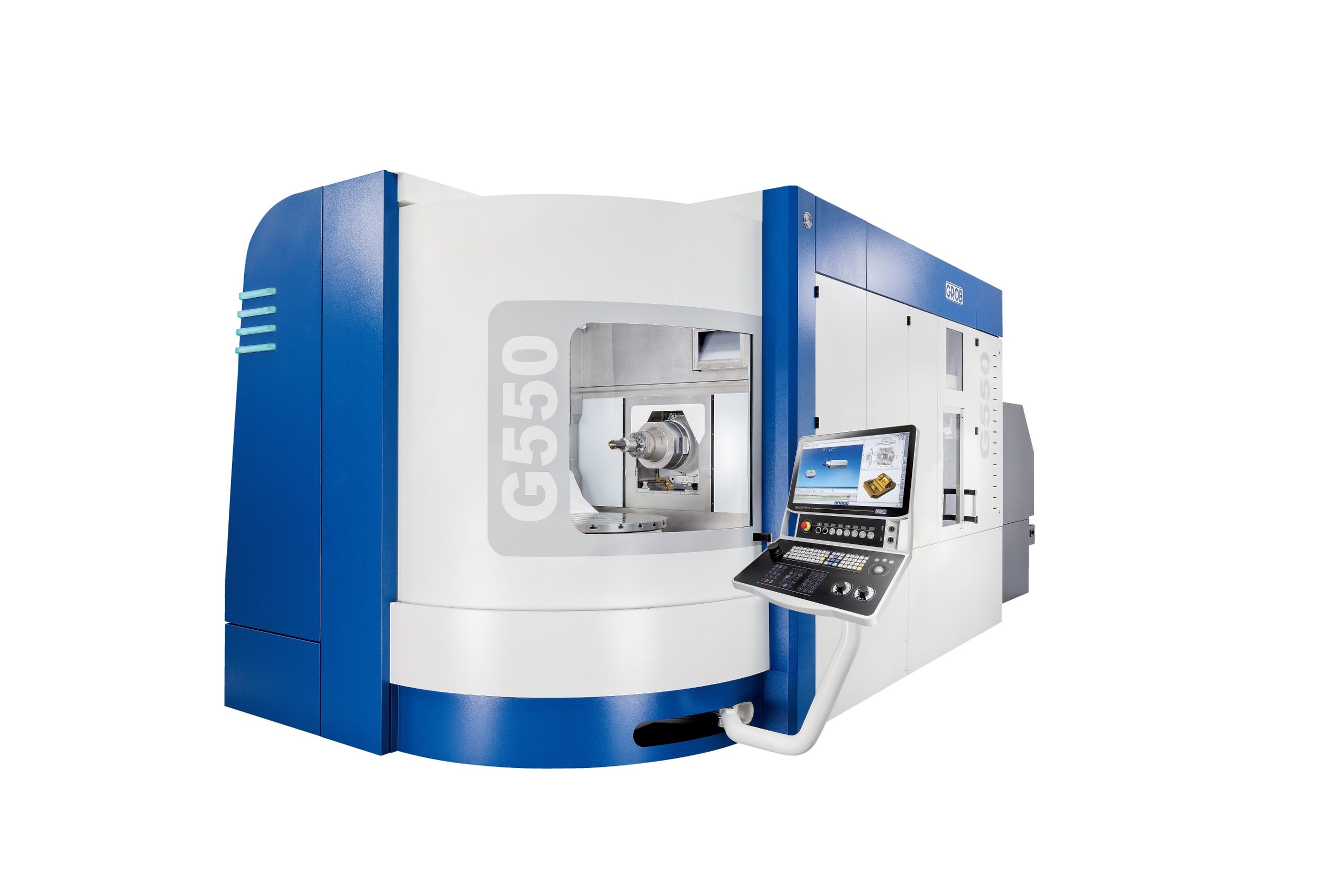

Following its debut in 2014, the Grob Group will be exhibiting for the third time at MACH on Stand 211 in Hall 19. In conjunction with Guhring, Grob will demonstrate the machining of a steel component on a G550 – Generation 2 machining centre.

The latest Generation 2 horizontal 5-axis universal machining centre will showcase a die and mould component highlighting the maximum tool length available on a Grob. The machine will have the pioneering GROB4 Pilot control system and is supplied with a 16,000rpm HSK-A63 spindle with 206Nm of torque and an output of 32kW.

The second-generation machine is characterised by a modern design and some new assemblies and thus provides a whole range of advantages for customers. The G550 – Generation 2 has high dynamic performance and stability as well as a narrow design and a marked reduction in chip-to-chip time. The maximum tool length has been increased to 700mm and the number of HSK-A63 tools has been increased to 137. Like its little sister, one of the impressive features of the G550 – Generation 2 is its ergonomically favourable tool-loading point at the operator’s end.

The 5-axis universal machining centre is an optimally designed machine for the wide range of requirements of individual manufacturing sectors. Now available in the second generation, Grob engineers have integrated several technical innovations and advancements that substantially improve the universal machines. Due to a repositioning of the tool magazine, Grob has reduced the machine width from 2.45m to 2m, thus achieving a significantly smaller machine footprint. Furthermore, the tool capacity now comprises 60 slots, which can easily be increased to 120 slots with the double disk machine.