As the exclusive distributor of DN Solutions’ and Zayer machine tools, Mills CNC has recently supplied ABG Rubber & Plastics Ltd with two new multi-tasking lathes. The precision subcontract specialist is part of the Oadby group of companies.

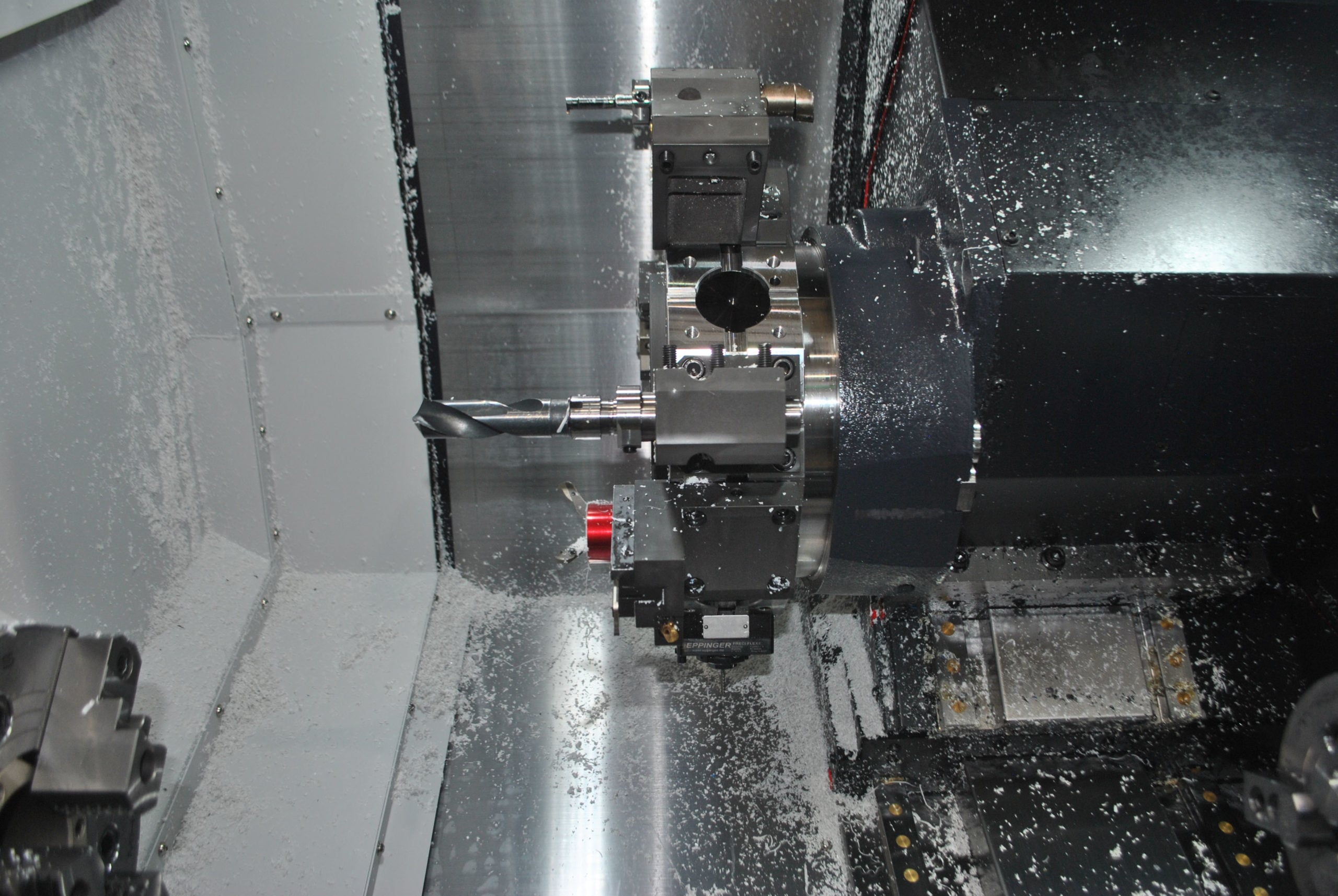

The 10” chuck machines are both FANUC-controlled Lynx 2600SY turning centres that were installed at ABG’s 20,000sq/ft manufacturing facility in Northampton in October. The new Lynx lathes which are the first DN Solutions’ (Doosan) machines to be acquired by ABG, have significantly strengthened the company’s CNC machining resources.

The new lathes are fitted with bar pullers to facilitate a measure of automated operation. Since installation, the machines have been put through their paces, processing a wide range of high-precision parts such as bushes, bearings, shafts, wheels, rollers and cams from a wide range of engineering plastics like PEEK, PVDF, Nylon 6 and Polyethylene. These parts, machined and supplied in medium to large volumes, are often characterised by their intricate features and tight tolerances. They are machined for a diverse range of customers in the automotive, medical, pharmaceutical, materials handling, construction, food & beverage and processing industries.

Despite their relatively recent installation, the turning centres have already made their mark, dramatically improving ABG’s productivity and process efficiencies. ABG’s General Manager Chris Woolley says: “Our Lynx lathes are equipped with productivity-enhancing technology features and driven tooling capability that enables us to machine complex, high-precision parts in ‘one hit’. This ability to reduce set-up and cycle times is helping us improve our process efficiencies and it is already having a positive impact on lead times and the cost-per-part.”

ABG Rubber & Plastics, acquired by the Oadby group of companies in 1998 is a manufacturer of engineering plastics and industrial rubber parts with a reputation based on quality and technical excellence. The ISO:9001 and ISO:14001 certified company has a well-resourced production facility that combines with the considerable technical skill and experience of its staff to offer a complete one-stop solution.

ABG’s Technical Manager, Anthony Morbey adds: “The pandemic hurt certain sectors that we serve, and this naturally caused a hiatus in our investment plans. Thankfully, this was short-lived and, with demand returning for our machining services, we moved quickly and decisively to upgrade and strengthen our CNC turning resource.”

Having previously invested in a lathe with driven tooling capabilities as well as sliding head technology and 5-axis machining centres, ABG did not need to be convinced about the productivity and performance benefits of multi-axis machine tools and the competitive edge they provide. As Anthony Morbey continues: “After careful analysis of our machining operations, we determined that we needed two new high-performance CNC lathes with Y-axes and sub-spindles to meet our immediate and future turning requirements. Space is at a premium within our production facility, which is why both lathes needed to be compact.”

Although ABG had not previously invested in DN Solutions’ or Doosan machine tool technology, the company placed an order for two Lynx 2600SY machines. “We researched the market by talking to several suppliers, customers and third parties. It soon became apparent that DN Solutions’ machines have a great reputation for their performance and reliability,” explains Chris Woolley.